Stirring friction welding tool capable of welding with rolling

A technology of friction stir and welding, which is applied in the direction of manufacturing tools, welding equipment, non-electric welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

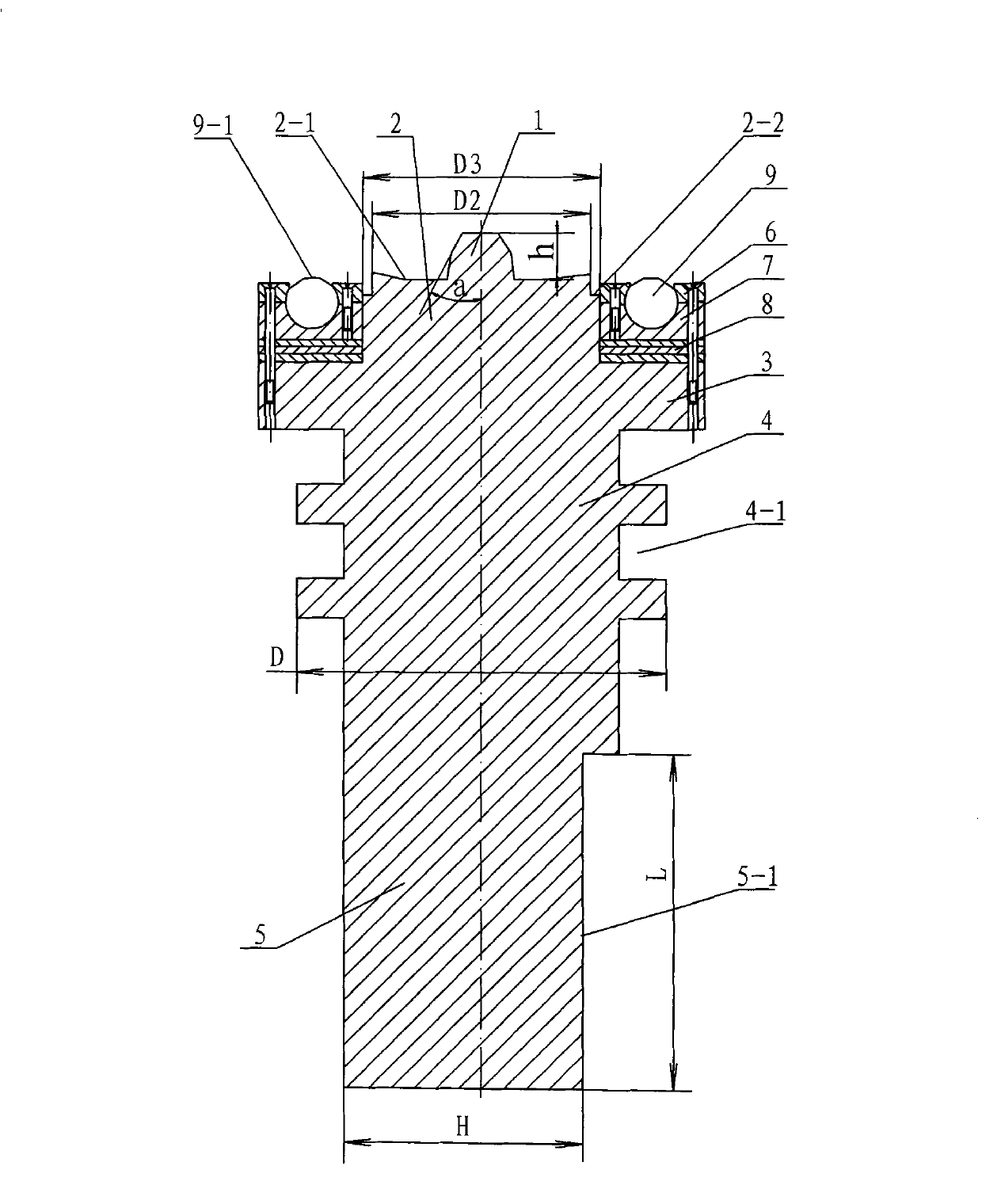

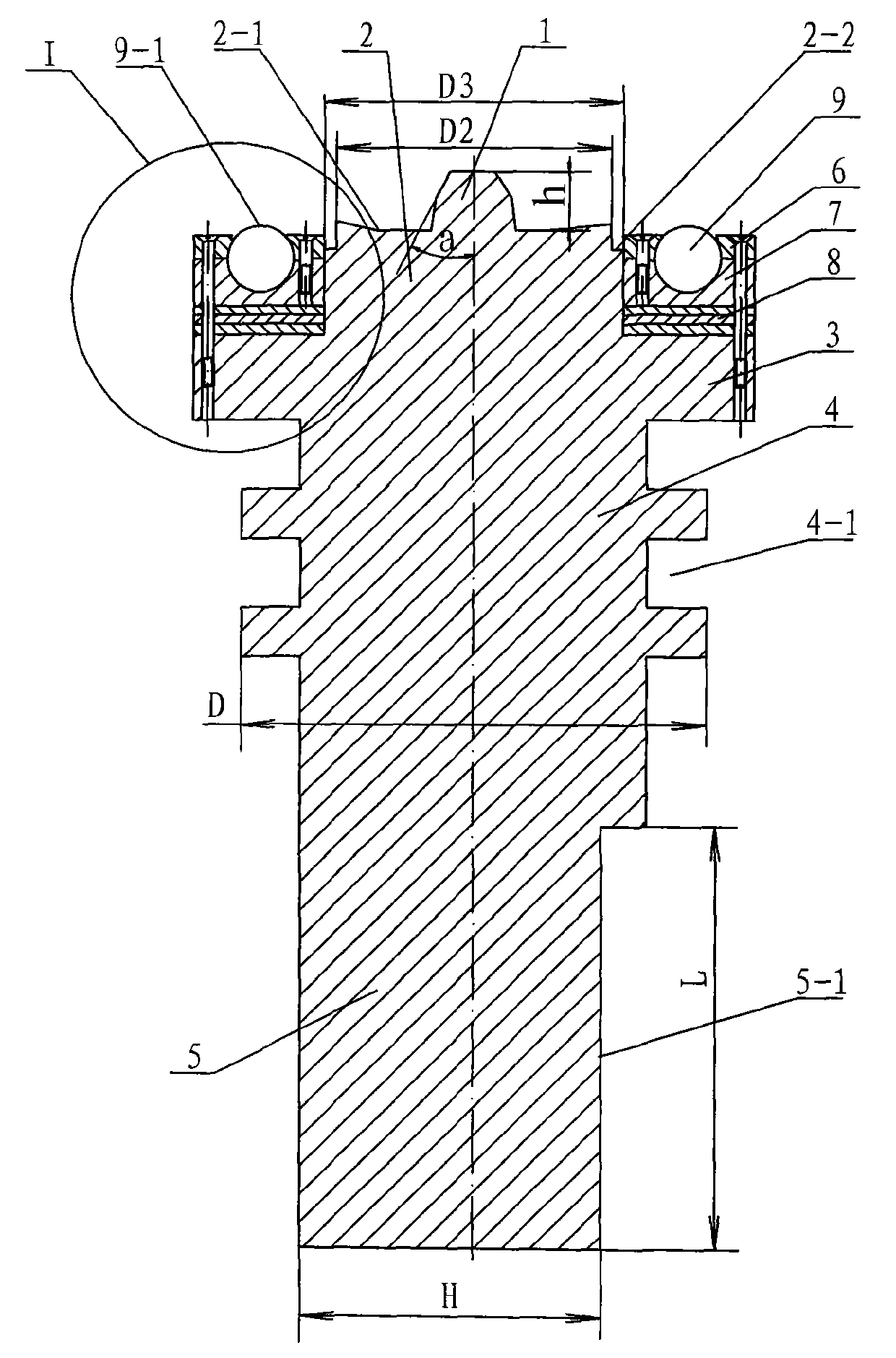

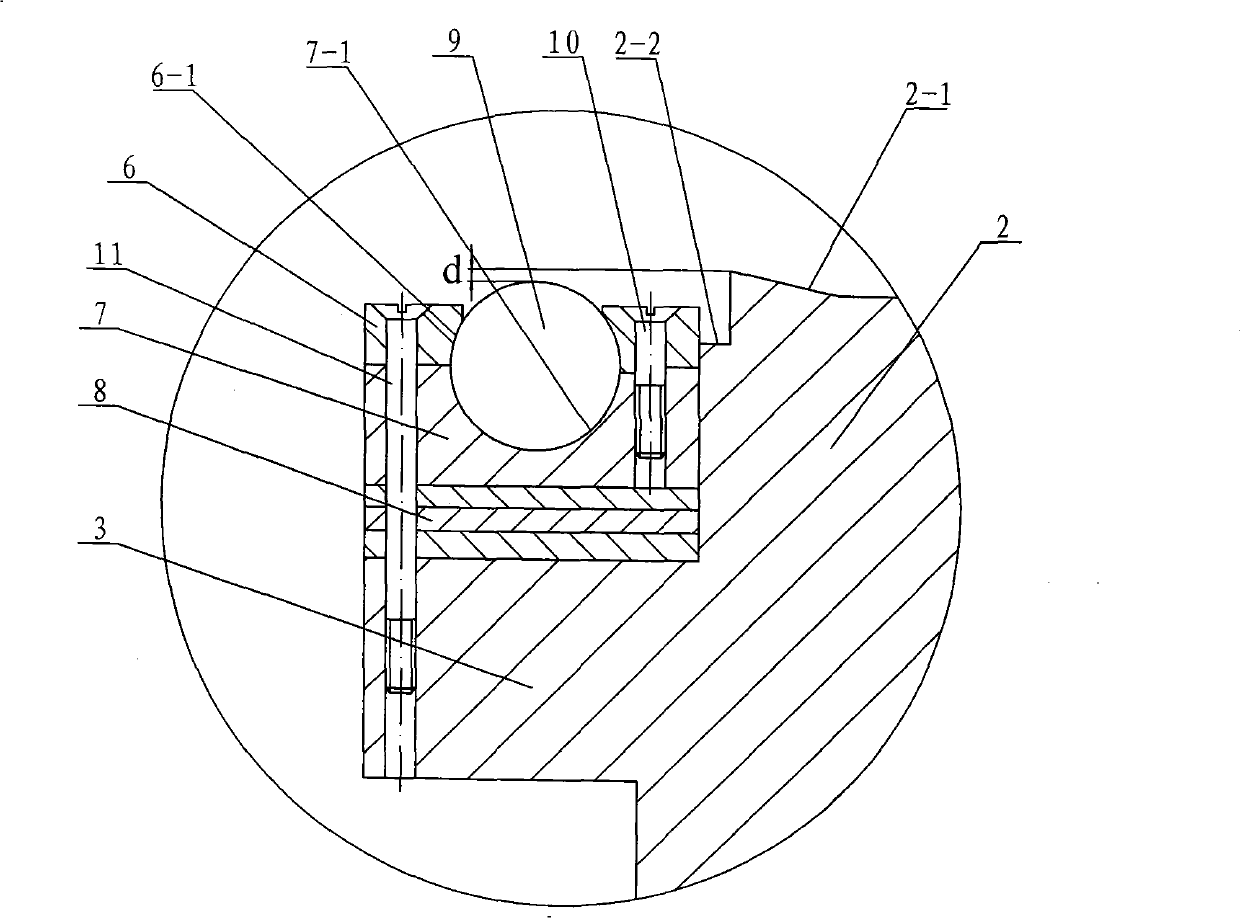

[0010] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment, this embodiment comprises stirring head, upper clamping body 6, lower clamping body 7, at least one spacer 8 and at least three evenly distributed rolling balls 9, stirring head is made up of stirring pin 1, shaft shoulder 2. The positioning shoulder 3, the cylinder 4 and the clamping body 5 are composed of the stirring needle 1, the shaft shoulder 2, the positioning shoulder 3, the cylinder 4 and the clamping body 5 are sequentially integrated from top to bottom, and the stirring needle 1 Located at the axis of the front end of the shaft shoulder 2, the clamping body 5 is provided with a clamping surface 5-1 to fit with the inner hole of the stirring spindle and locked with a fastening screw. The stirring needle 1 is a cone, and the shaft The upper end surface of the shoulder 2 is a concave shoulder surface 2-1 whose outer edge is higher than the center, the outer diameter of the u...

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 and Figure 4 To illustrate this embodiment, the rolling surface 9-1 exposed outside the end surface of the upper clamping body 6 on the rolling ball 9 of this embodiment is a spherical surface or a plane processed into a smooth chamfer. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination figure 1 and Figure 4 To illustrate this embodiment, the number of rolling balls 9 in this embodiment is 3-8, the diameter of the rolling balls 9 is 5-12mm, and the spherical radian of the rolling surface 9-1 is 90°-150°. This is designed to prevent the carbide ball from falling out. A single rolling ball 9 is positioned, and there is no mutual interference between rolling balls 9 and rolling balls 9 . Other components and connections are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com