Continuously vertically lifting conveying platform supported bilaterally

A vertical lifting and conveying platform technology, which is applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of inclination of the conveying platform, poor work reliability, and large space occupation, and achieve stable work, high work reliability, The effect of taking up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

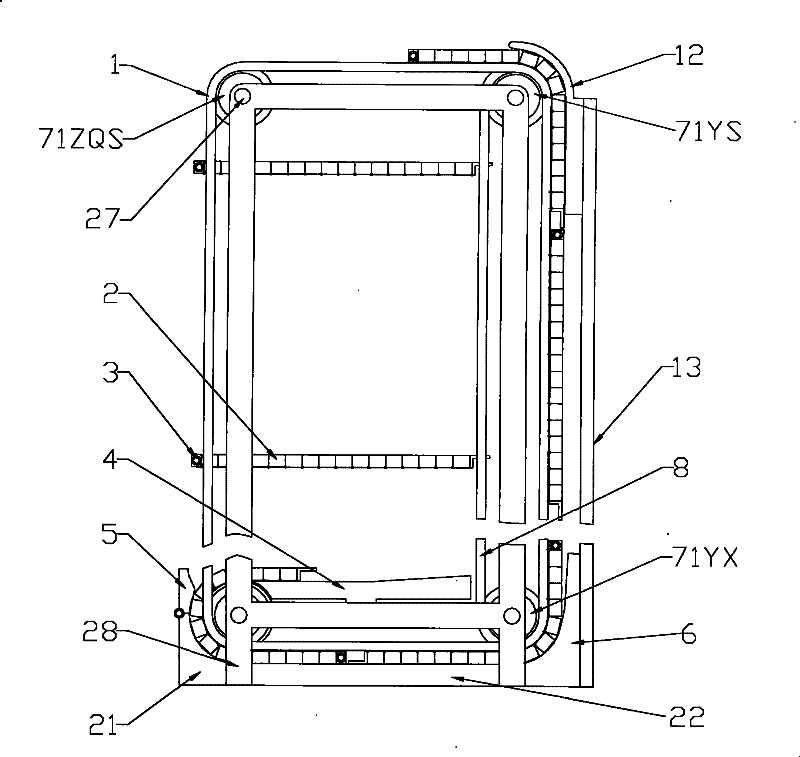

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] Such as Figure 3-Figure 11 shown.

[0035] See Figure 4 , Figure 6 , the present invention bilaterally supports the continuous vertical lifting conveying platform device, which includes a bracket 28 , a motor 23 mounted on the bracket 28 and a reducer 10 connected to the motor 23 .

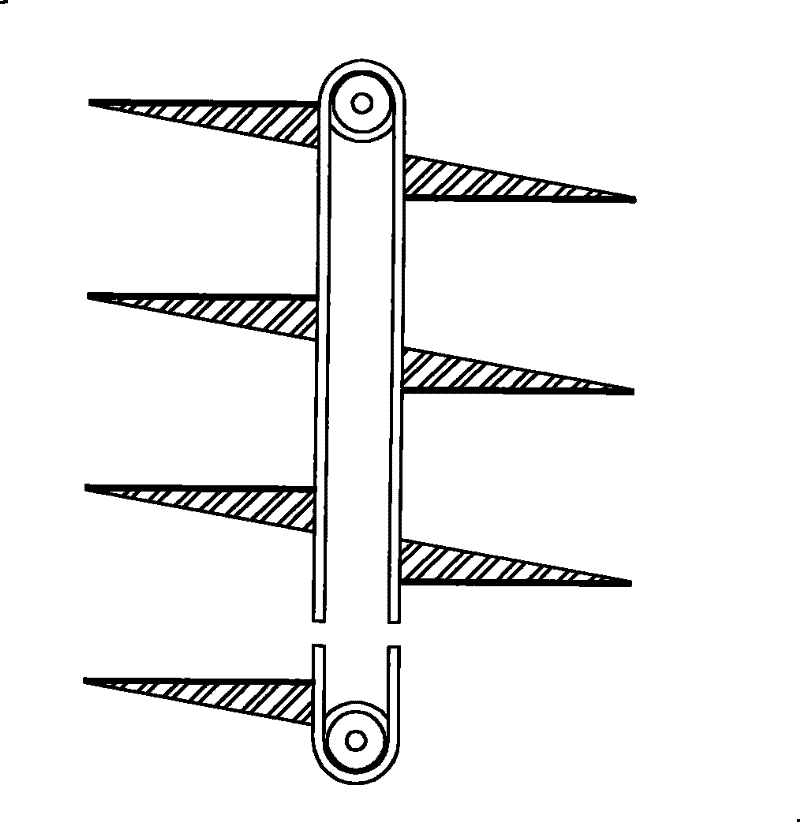

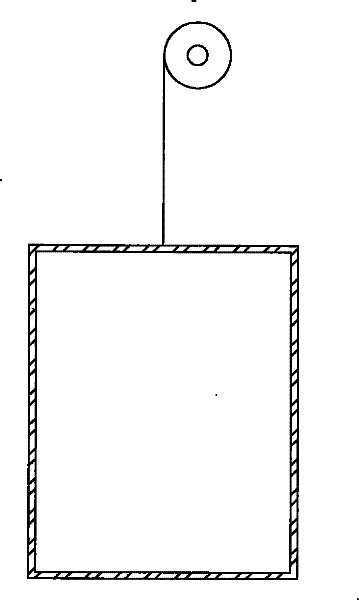

[0036] See image 3 , Figure 4 , Figure 5 ,, Figure 6 , Figure 7, the double-sided supporting continuous vertical lifting conveying platform device of the present invention also includes two sets of identical chains and sprockets, and each set of chains and sprockets includes a long chain and four sprockets engaged with it, that is, upper left, upper right, lower left, and lower right Four sprockets, the long chain is connected end to end to form a closed long chain ring 1. Every group of chains and sprockets also includes a short c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com