Serial rare-earth borate laser glass and preparation method and purpose of same

A laser glass and borate technology, applied in the direction of active medium materials, etc., can solve the problems of complex crystal growth process, and achieve the effects of good optical uniformity, easy processing and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

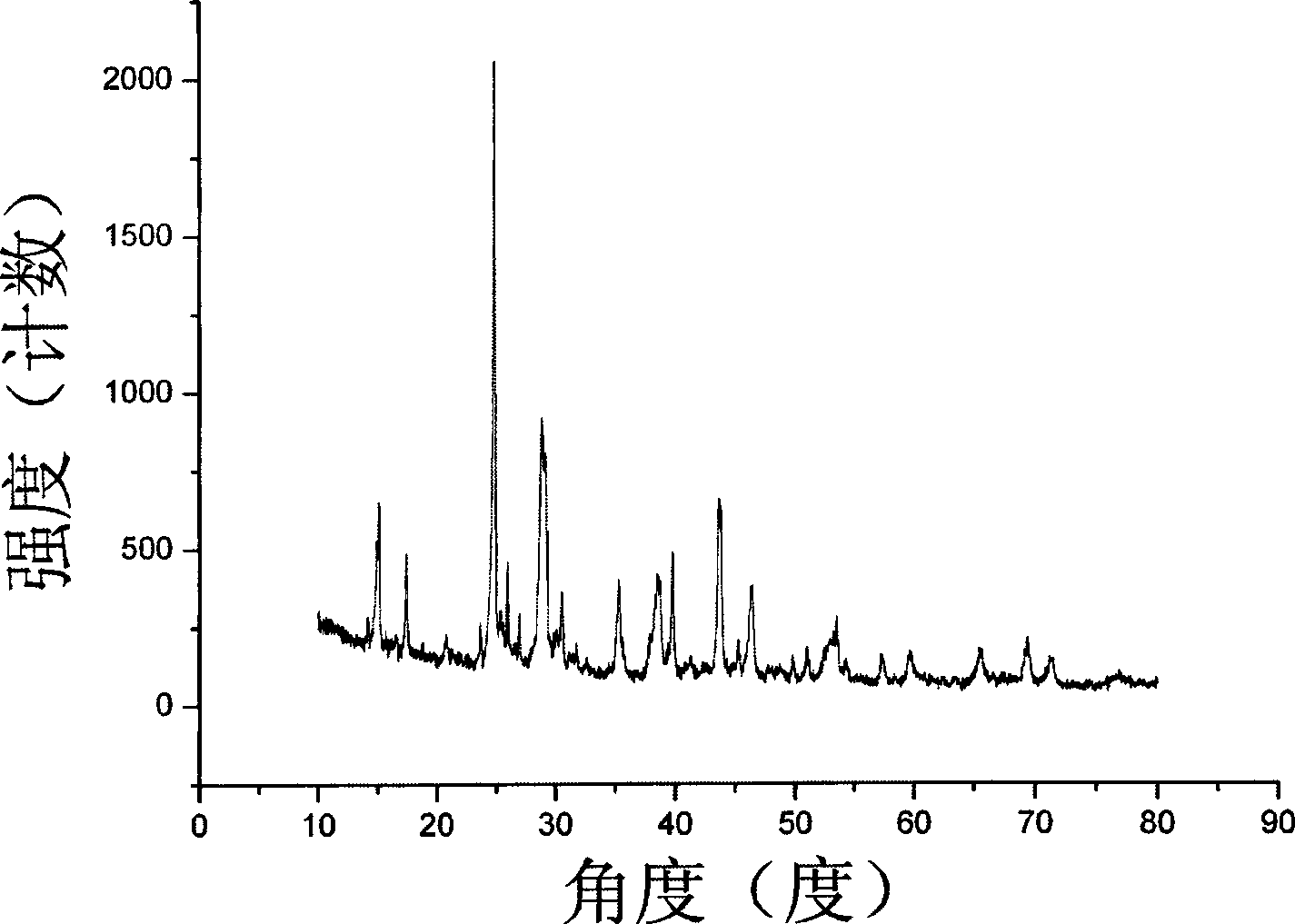

[0023] Example 1: Series ReBa 3 B 9 o 18 (Re is a rare earth element other than La and Ce) laser glass preparation method

[0024] Will Re 2 o 3 , BaCO 3 and H 3 BO 3 Mix evenly in a molar ratio of 1:3:9.1 (Re is a rare earth element other than La and Ce); in the muffle furnace, the mixed raw materials are sintered at 800°C-900°C for multiple times, that is: the first time After sintering, take it out, grind it evenly again, and sinter it again, repeat this several times to get ReBa 3 B 9 o 18 (Re is the pure material of rare earth elements other than La and Ce); melt the synthesized pure material in a crucible at a melting temperature of 1000°C-1100°C, and raise the temperature of the melt to 30-50°C above the melting temperature and keep it warm , after the melt is fully melted, it returns to the melting temperature of the melt and remains in the melting state; let the melt cool naturally with the furnace, and the series ReBa 3 B 9 o 18 (Re is a rare earth eleme...

Embodiment 2

[0025] Example 2: Series Re 1-x Re' x Ba 3 B 9 o18 (0<x<1; Re, Re' is a rare earth element other than La, Ce) laser glass preparation method

[0026] Will Re 2 o 3 , Re' 2 o 3 , BaCO 3 and H 3 BO 3 According to the molar ratio (1-x):x:3:9.1 mixed evenly (Re, Re' is La, rare earth elements other than Ce) where 01-x Re' x Ba 3 B 9 o 18 (01-x Re' x Ba 3 B 9 o 18 (0

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com