Method and device for collecting, separating, purifying and cleaning new energy by utilizing carbon making waste gas

A separation device and new energy technology, applied in the direction of energy input, combustible gas purification, climate sustainability, etc., can solve problems such as air pollution and environmental pollution, achieve the effects of inhibiting growth, reducing the amount of pesticides, and keeping the air fresh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The method and device for collecting, separating and purifying clean and environmentally friendly new energy by using carbon-making waste gas of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation of the present invention.

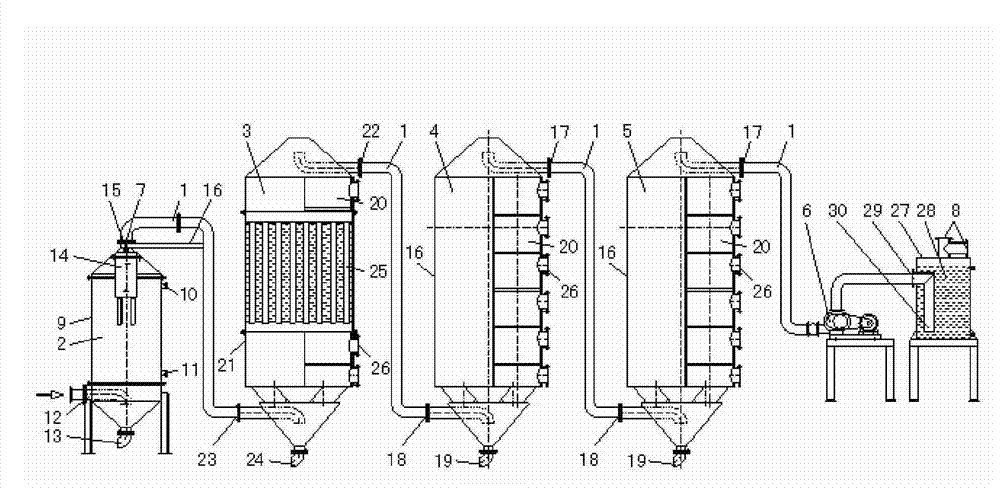

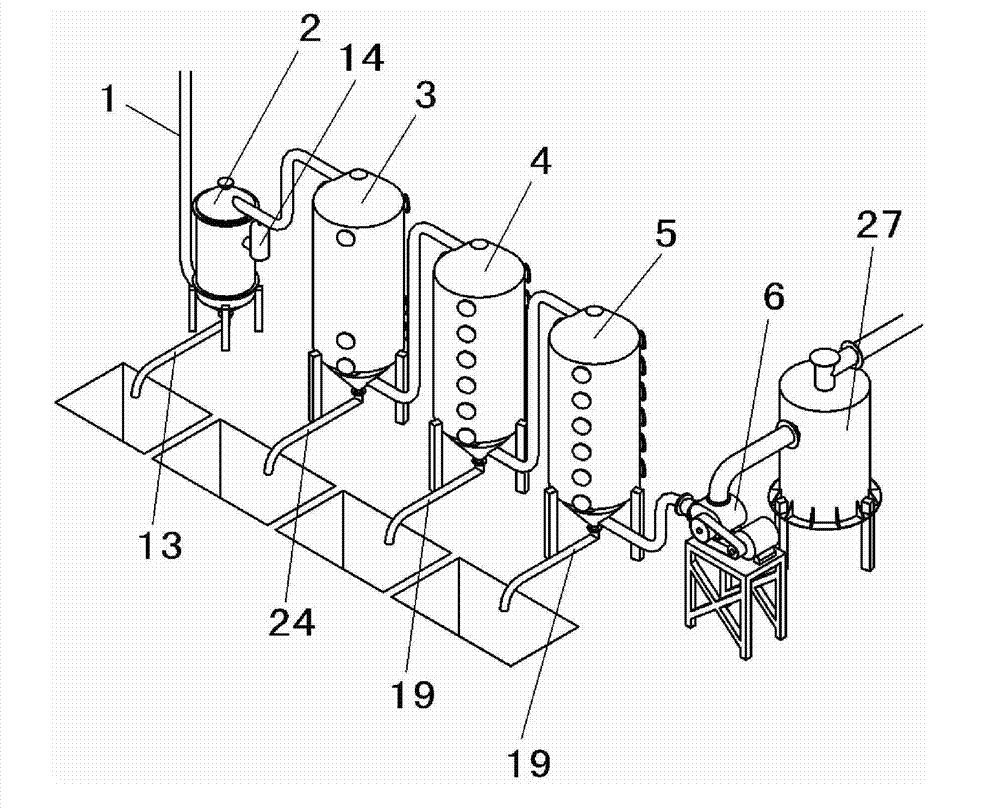

[0018] Example. A method and device for collecting, separating and purifying clean and environmentally friendly new energy by using carbon-making waste gas. The method of the present invention is as follows: figure 1 and figure 2 As shown, the method is to make the charcoal flue gas pass through the waste heat boiler, the wood vinegar liquid separation device and the two-stage wood tar separation device in sequence to separate the wood vinegar and wood tar in the charcoal flue gas to obtain pure combustible gas. The steam generated during the heating process of the water in the furnace body by the waste heat boiler is mixed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com