Patents

Literature

30results about How to "Not easy to get insects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Planting method for combined circular agriculture

The invention discloses a planting method for combine circular agriculture, which comprises the following steps of planting evergreen first high-bar trees and / or undershrub around cultivated fields of cash crop to form a sand storm protection zone for the cash crop; planting second high-bar trees at the periphery of the wind storm protection zone to form a hedgerow zone of the cash crop; and planting first insect pest prevention plants between the wind storm protection zone and the hedgerow zone to form a first insect pest prevention zone. The method provides appropriate growth environment for the cash crop by planting various trees and undershrub plants to respectively form the wind storm protection zone, the first insect pest prevention zone and the hedgerow zone, thereby preventing the cash crop from being damaged by sand and insect pests, reducing using amount of pesticide and improving quality of agricultural products.

Owner:HUANGSHAN DUOWEI BIOLOGICAL GRP

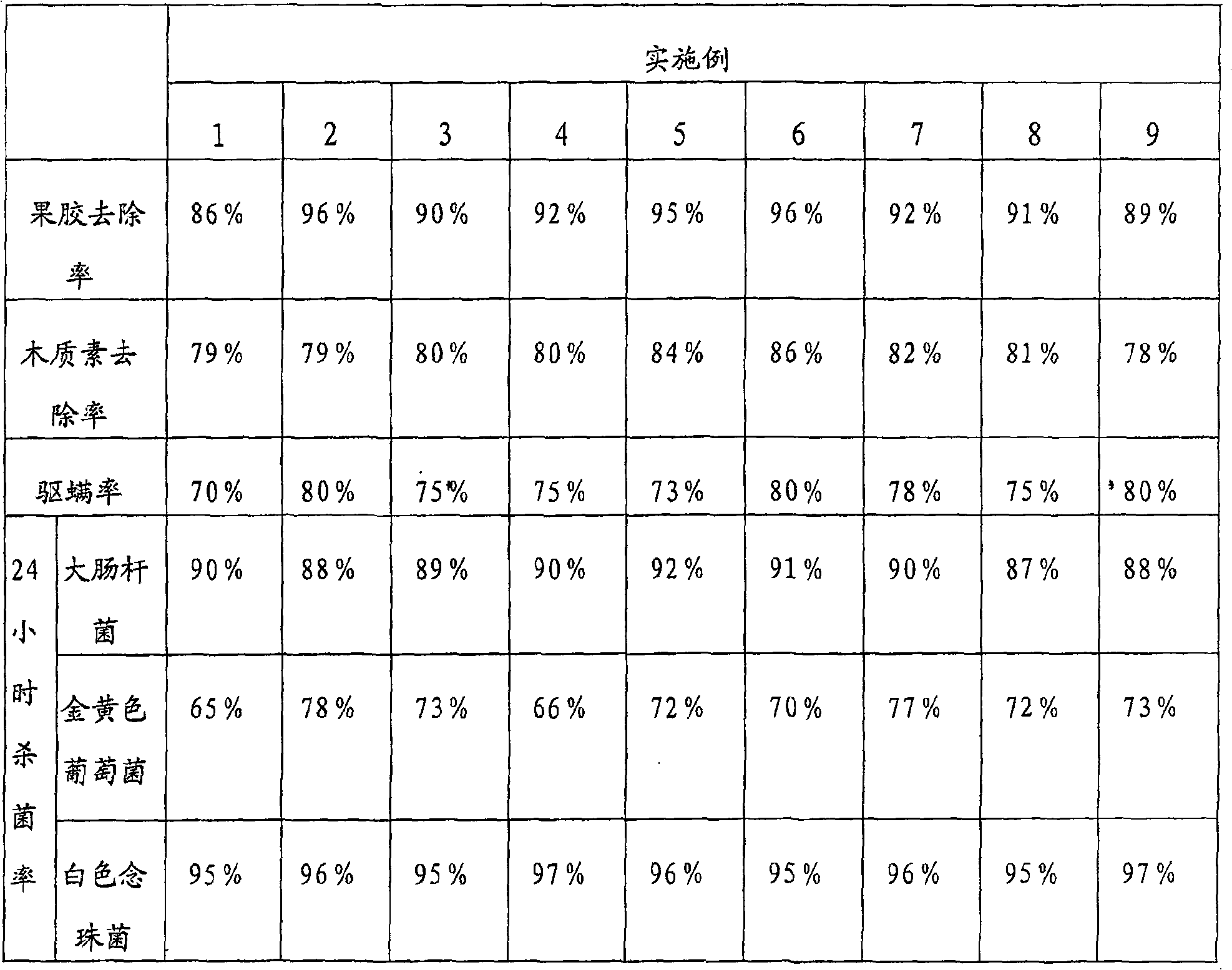

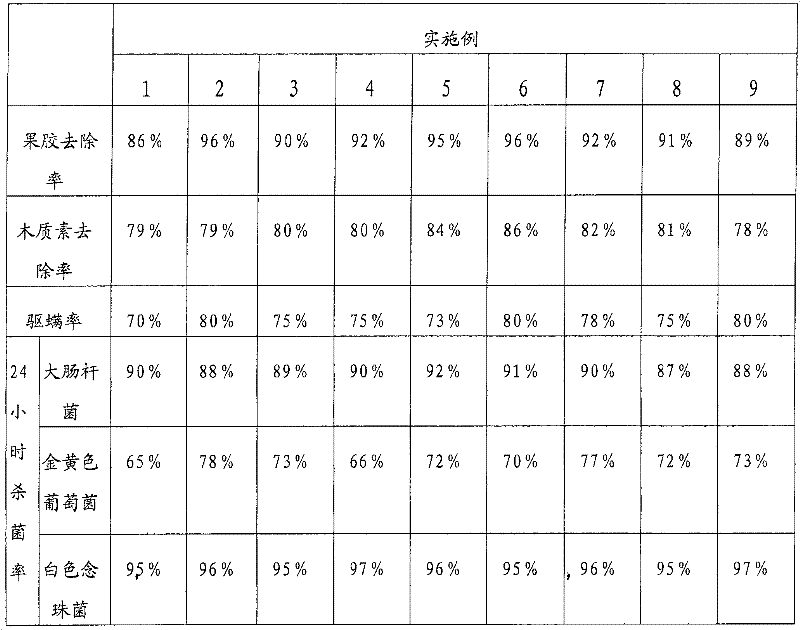

Method for manufacturing insole with jute fiber

ActiveCN101167606AEfficient removalWeaken joint forceInsolesFibre treatment to obtain bast fibreFiberPectinase

A method for manufacturing insoles by jute fibers comprises treating jute fibers with the complex enzyme de-gelatinizing, wherein, the complex enzyme de-gelatinizing treatment uses complex enzyme aqueous solution which is formulated by pectase and laccase to provide the de-gelatinizing treatment to jutes, adjusting the pH value of the complex enzyme aqueous solution to be more than or equal to 4.0 but less than 5.0 when the complex enzyme de-gelatinizing treatment is carried out, elevating the temperature to 35 DEG C to 65 DEG C for 20-120 minutes, and then adjusting the pH value of the solution to be 7.5 to 9.5, keeping the temperature under 40 DEG C to 70 DEG C for 20-120 minutes, enzyme-devitalizating the jutes which are treated by the complex enzyme, mixing the de-gelatinized jute fibers with the chemical fibers, carding, net-spreading, and needling the mixed fibers, hot-pressing the needled mixed fibers and molding. The insole manufactured by the method of the invention is very comfortable when in use, and is not urticant in feeling when in use, good in bacteria repellency, not easily wormy, and strong in air permeability, hygroscopicity, and moisture character.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

Method for manufacturing seat cushion with jute fibre

ActiveCN101172571AGood puffing effectImprove acupuncture effectUpholstery fillingFibre treatment to obtain bast fibrePectinaseAntibiosis

The invention relates to a manufacturing method of a seat cushion made of jute fiber. The method comprises the following steps: firstly, the soaking is performed to jute in compound enzyme water solution prepared by pectase and laccase, and the weight ratio of the compound enzyme water solution and the jute is 12 : 1 to 40 : 1; the pH value of the compound enzyme water solution is firstly adjusted into 4.0 to 6.5, and the compound enzyme water solution is warmed up to 35 to 65 DEG C, and the temperature is kept for 20 to 120 minutes; and then pH value of the compound enzyme water solution is adjusted to more than 8.0 and less than and equal to 9.5, and the compound enzyme water solution is kept for 20 to 120 minutes at 14 to 70 DEG C; then the enzyme inactivation process is performed to the jute processed through the compound enzyme; secondly, jute fiber after being degumed is mixed with chemical fiber, and carding, mesh placement and needling are performed to the chemical fiber; thirdly, the mixed fiber after being needled is thermally pressed and molded; fourthly, a sleeve body is coated. The seat cushion manufacuted by the invention is soft and comfortable, has no urtication feeling when being used by people, and has good antibiosis and anti-acarine performance.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

Method and system for waste therophyte high-efficiency clean environment-protective cycled comprehensive utilization

InactiveCN101519598AWide range of usesPlay the role of antibacterial and sterilizingBiofuelsSpecial form destructive distillationCarbonizationWater block

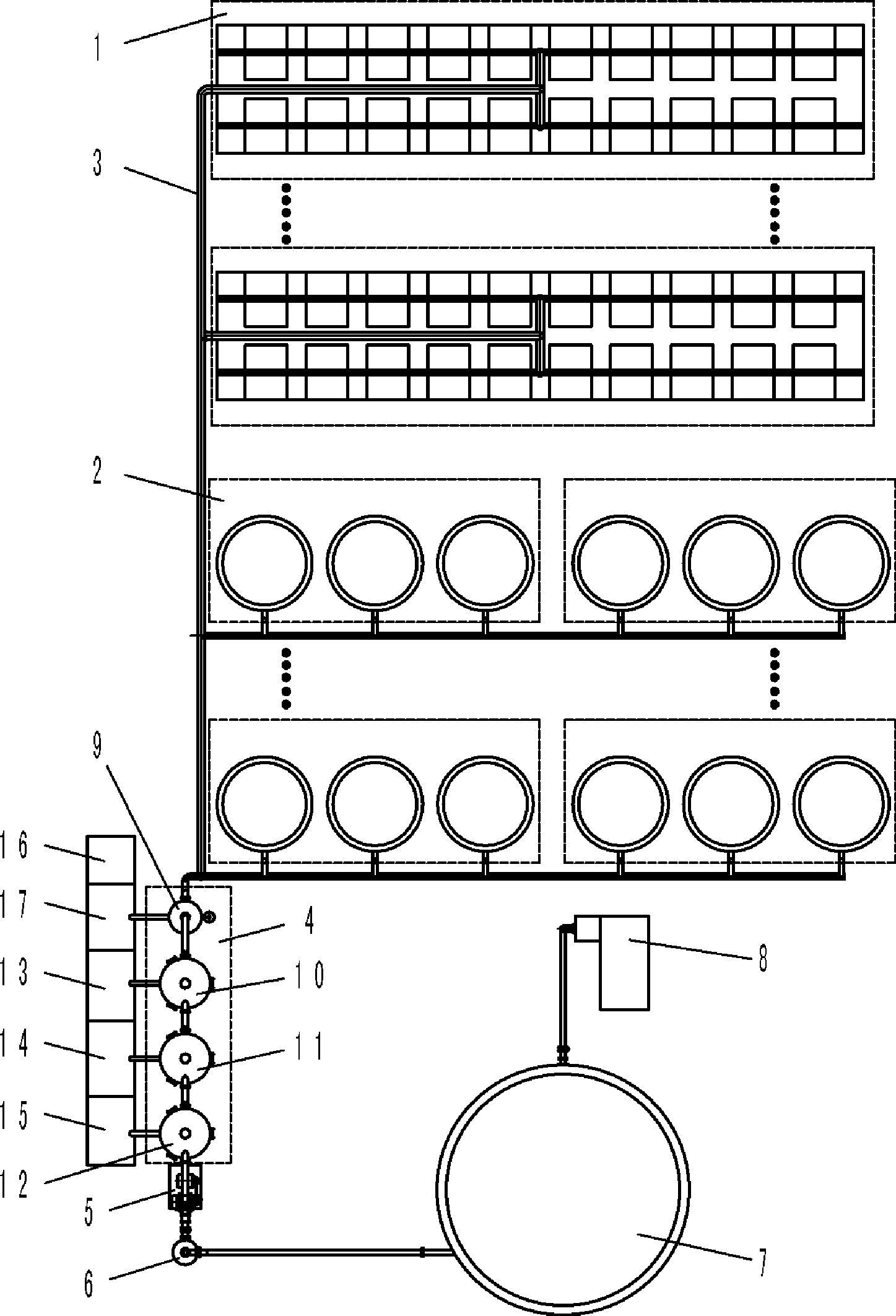

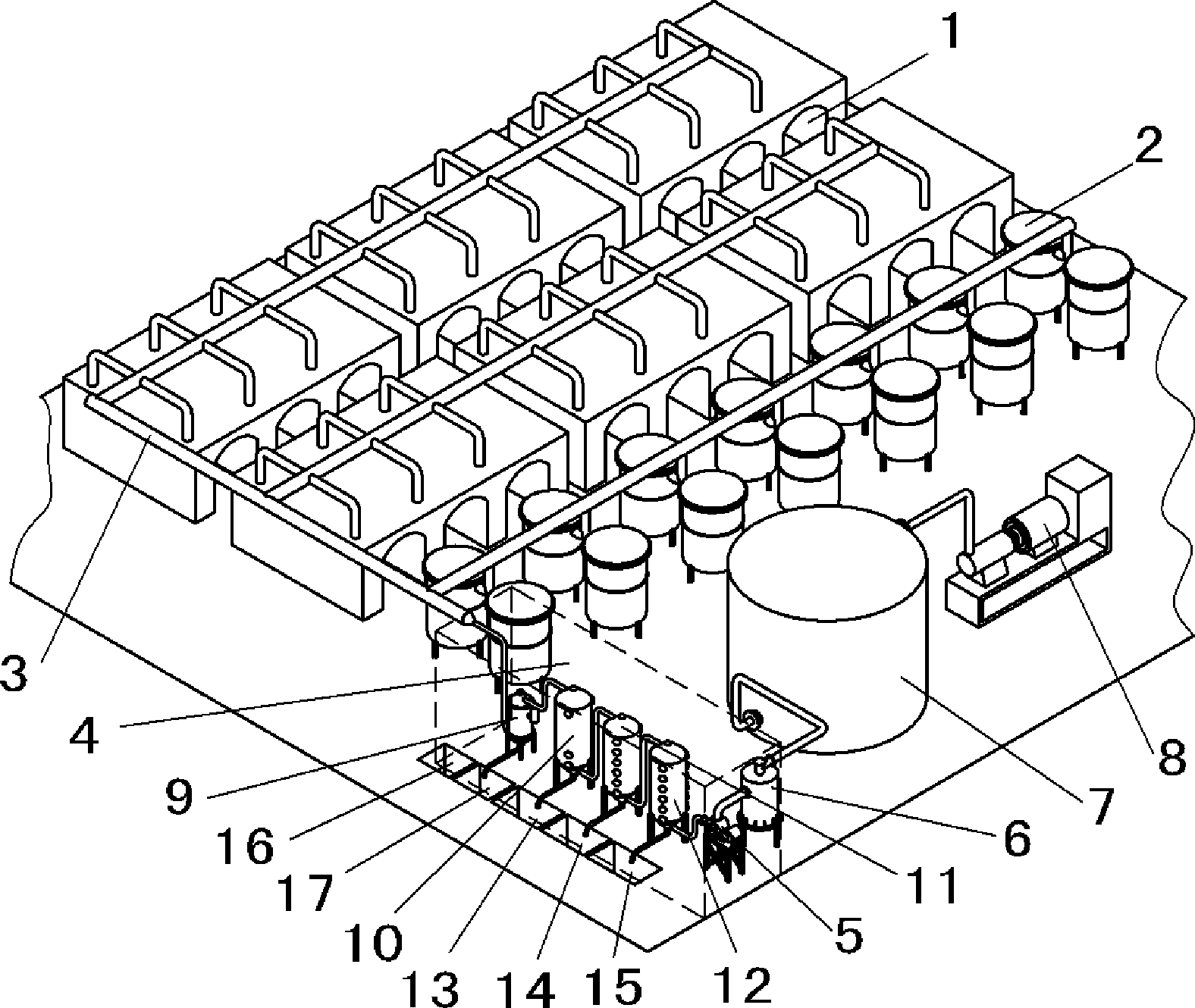

The invention discloses a method and a system for waste therophyte high-efficiency clean environment-protective cycled comprehensive utilization. In the method, waste therophyte is utilized to make machine-made charcoal, pyroligneous and woodtar in smoke gas generated in the charcoal making process are separated from the smoke gas by a separation device, the pyroligneous and the woodtar are taken as chemical materials, and the separated smoke gas is taken as fuel gas. The device comprises a charcoal making machine kiln set (1) and a vertical carbonization furnace set (2); the charcoal making machine kiln set (1) and the vertical carbonization furnace set (2) are connected with an inlet of a cooling and purifying system (4) through a pipeline (3); an outlet of the cooling and purifying system is connected with a gas storage holder (7) through a blower (5) and a water block (6) in sequence; and the gas storage holder is connected with a fuel gas generator (8) through the pipeline. The invention utilizes waste materials as raw materials for making charcoal, separates the chemical materials from waste smoke gas generated in the charcoal making process, uses the separated smoke gas as gas fuel, turns waste into treasure, effectively prevents pollution to the environment and has extremely good social and economic benefits.

Owner:李观德

Processing method for flame-retardant handicraft weaving bamboo canes

InactiveCN106393366AAvoid damp and mildewExtended service lifeWood treatment detailsReed/straw treatmentSodium BentoniteChemical solution

The invention relates to the technical field of weaving processes, in particular to a processing method for flame-retardant handicraft weaving bamboo canes. The processing method for flame-retardant handicraft weaving bamboo canes is characterized by including the following steps of bamboo picking, bamboo beating, bamboo washing, peeling, soaking and drying. In the soaking step, a chemical solution is used for soaking and comprises, by weight, 0.4-0.6 part of ethyl silicon oil, 0.8-1 part of calcium carbonate ketone, 0.4-0.6 part of nonylphenol polyoxyethylene ether, 2-3 parts of ethyl alcohol, 80-120 parts of pure water and 2-3 parts of bentonite. The processing method can prevent bamboo canes from being affected with damp and going mouldy, the processed cranes are not prone to breed insects, good in flame-retardant performance and high in strength, and the service life of woven handcrafts is prolonged.

Owner:ANHUI MEIJING ARTS & CRAFTS CO LTD

Health-care wicker grassmat

InactiveCN102396935AWith verminNot easy to get insectsSenses disorderNervous disorderPhysicsPolyester

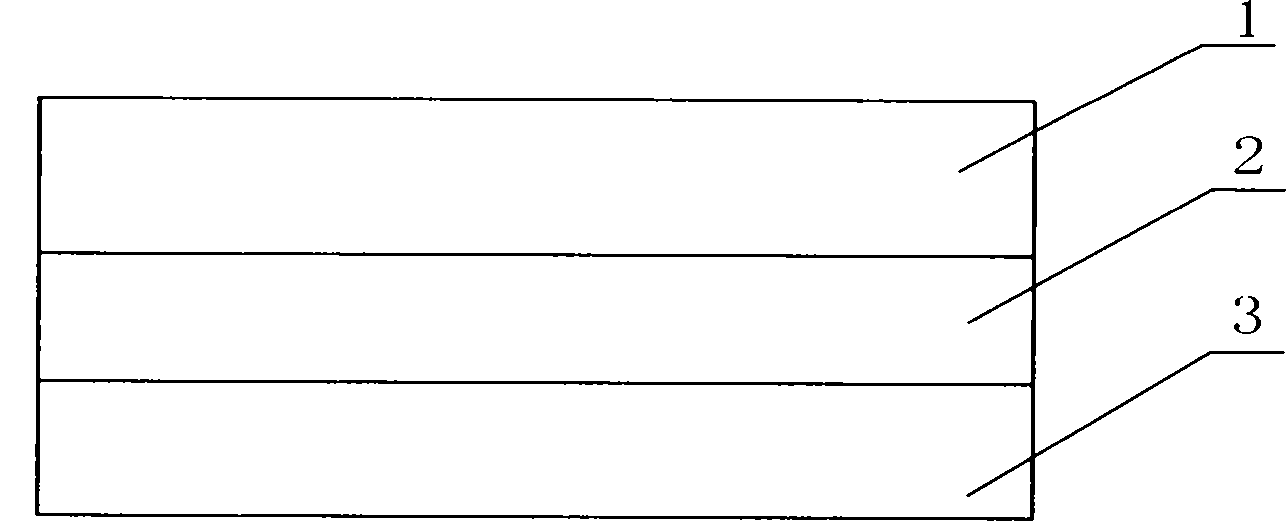

The invention discloses a health-care wicker grassmat, which comprises a wicker grassmat body, an intermediate layer and a liner layer that are formed on the back face of the grassmat; the wicker grassmat is weaved by finely-selected high-quality wickers; the intermediate layer is positioned on the back face of the grassmat and is a middle part between the grassmat face layer and the liner layer; and the liner layer is antimicrobial polyester permeable cloth. The wicker grassmat disclosed by the invention not only has the advantages of light weight, no smell, sanitation, firmness and durability, but also has the health-care efficacy of eliminating phlegm and relieving cough, relieving convulsion and sleeping peacefully, refreshing brain and improving eyesight, preventing apoplexy, dispelling rheumatism and the like.

Owner:NANTONG JINYUE FASHION DESIGN

Insect-killing and damp-proof treatment method for handicraft weaving rattans

InactiveCN106363749AAvoid damp and mildewExtended service lifeWood treatment detailsReed/straw treatmentChemical solutionAlcohol

The invention relates to the technical field of weaving processes, in particular to an insect-killing and damp-proof treatment method for handicraft weaving rattans. The insect-killing and damp-proof treatment method for handicraft weaving rattans is characterized by comprising the following steps of rattan sorting, rattan beating, rattan washing, peeling, soaking and drying. A chemical solution is used for soaking in the soaking step and comprises, by weight, 0.4-0.6 part of iodine, 0.8-1 part of polyvinylpyrrolidone, 0.4-0.6 part of nonylphenol polyoxyethylene ether, 2-3 parts of ethyl alcohol, 80-120 parts of pure water and 2-3 parts of bentonite. The insect-killing and damp-proof treatment method can prevent rattans from being affected by damp and going mouldy, and prevent rattans from breeding insects easily, rattans are good in flame retardant effect and high in strength, and the service life of a woven product is prolonged.

Owner:ANHUI MEIJING ARTS & CRAFTS CO LTD

Method for repairing and renovating medium and large bird specimen

InactiveCN102737541AIntegrity guaranteedSave traditional filling materialsEducational modelsFisheryMechanical engineering

The invention relates to a method for repairing and renovating a medium and large bird specimen. The method comprises the following steps of: (1) separating the specimen, i.e. the original medium and large bird specimens are separated so as to obtain the bird pelt; (2) resoftening and washing the pelt, i.e. placing the bird pelt into infusing liquid till the bird pelt becoming completely resoftened; and washing and draining the resofttened pelt, and drying the resofttened pelt with 40-60% drying degree; (3) repairing and sewing the pelt, i.e. repairing the damage part of the pelt by using an ordinary method so as to obtain the repaired bird pelt; (4) coating preservative, i.e. uniformly coating the powder preservative inside the repaired bird pelt; (5) manufacturing and fixing a support frame, i.e. manufacturing a support frame by using an ordinary method, wherein the support frame penetrates inside the repaired bird pelt after being manufactured; (6) filling and sewing, i.e. filling a pearl cotton fruit net inside the bird body; the bird body is sown after the filling so as to obtain the sown specimen; and (7) shaping and specimen fixing. The method is simple to operate; and the original specimen can be repaired and renovated on the basis that the specimen acquisition is not increased.

Owner:CHINA ACAD OF SCI NORTHWEST HIGHLAND BIOLOGY INST

Healthcare willow straw mat

The invention discloses a healthcare willow straw mat, and the willow straw mat comprises a mat surface layer and a mat substrate layer, wherein magnets are uniformly bonded on the mat surface layer, and the mat substrate layer is formed by drying and extracting after being immersed in traditional herbs. Compared with the prior art, the healthcare willow straw mat has remarkable advantages that the straw mat which is made of willow branches has the advantages of light weight, convenience and non-deformation, different from the straw material of an ordinary straw mat, the willow straw mat is uneasy for having insects and peculiar smells, and the willow straw mat is firm, durable and easy to store; the willow straw mat surface layer is provided with magnets, so that an effect for calming nerves and eliminating irritability is achieved; and the willow straw mat substrate layer is immersed in traditional Chinese medicine and has functions for cooling and refreshing brains, clearing away heat and toxic materials, calming the liver, improving eyesight, enhancing immunity and promoting the hematopoietic function.

Owner:顾岁芳

A method for storing and keeping chestnut fresh in a mechanical cold storage with humidity adjustment

ActiveCN104430841BInhibition of respirationNot easy to rotSeed preservation by freezing/coolingEngineeringPreservation methods

Owner:CHENGDE SHENLI FOOD

Preparation method of bamboo chips for weaving bamboo crafts

ActiveCN106738155BEasy to divideImprove toughnessWood treatment detailsReed/straw treatmentChemistry

The invention discloses a preparing method for bamboo strips used for bamboo craft weaving. The preparing method includes the following steps that firstly, a bamboo tube is put into first soaking liquid to be subjected to primary soaking for 1-2 days under the temperature ranging from 50 DEG C to 60 DEG C; secondly, the bamboo tube obtained after primary soaking is subjected to freezing treatment; and thirdly, the frozen bamboo tube is put into a second soaking solution to be subjected to secondary soaking for 1 h to 3 h under the temperature ranging from 50 DEG C to 60 DEG C, and the bamboo strips are obtained. The bamboo strips treated through the preparing method have good flexibility and are very suitable for weaving of various crafts.

Owner:GUANGXI POLYTECHNIC

Multifunctional wicker straw mat

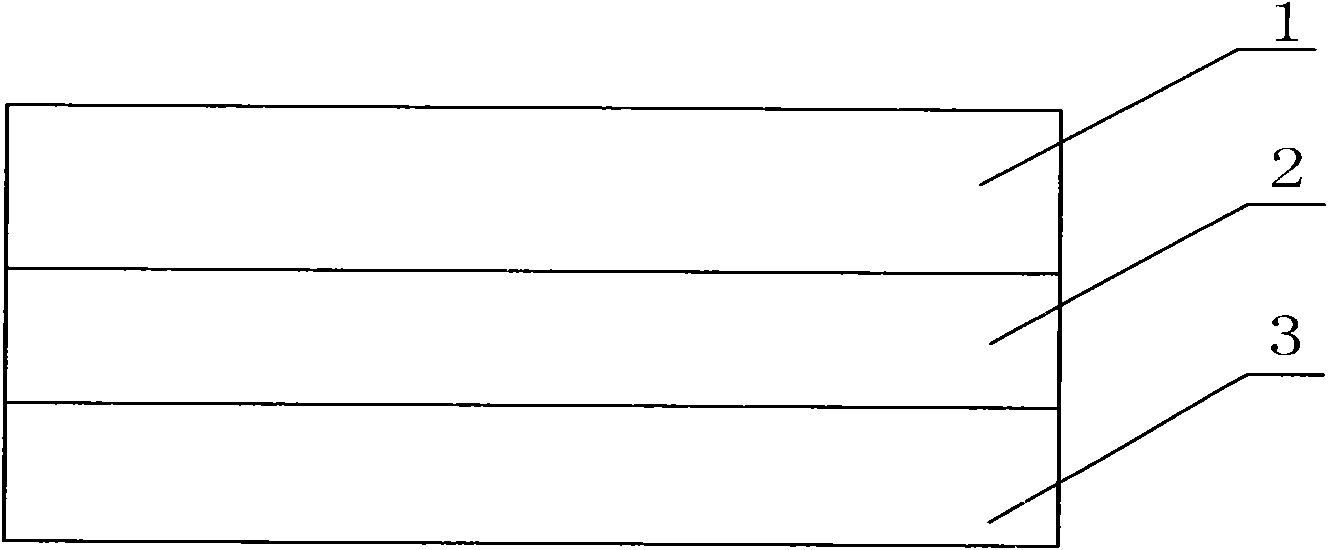

InactiveCN102462264AAvoid deformationNot easy to collectAntibacterial agentsAntipyreticFiberSurface layer

The invention discloses a multifunctional wicker straw mat, which comprises a mat surface layer and a mat substrate layer, wherein the mat surface layer is woven by wickers and serpentine beads, the substrate layer is bamboo fiber cloth soaked by traditional Chinese medicines, and the two layers are connected and fixed through cotton wires. The straw mat can be used for effectively massaging different acupuncture points of the body to realize the multiplex health care functions of relaxing the muscles to stimulate the blood circulation, softening the muscle to strengthen the bone, quenching the thirst to embellish the lung, nourishing the five organs and the hair and the like, and the multifunctional wicker straw mat also overcome the defects that the traditional straw mat has a single function, in addition, the ventilation effect cannot be realized, the traditional straw mat is easily affected with damp, the deformation is easily generated, insects are easily grown on the traditional straw mat, and the traditional straw mat is unfavorable for storage.

Owner:NANTONG JINYUE FASHION DESIGN

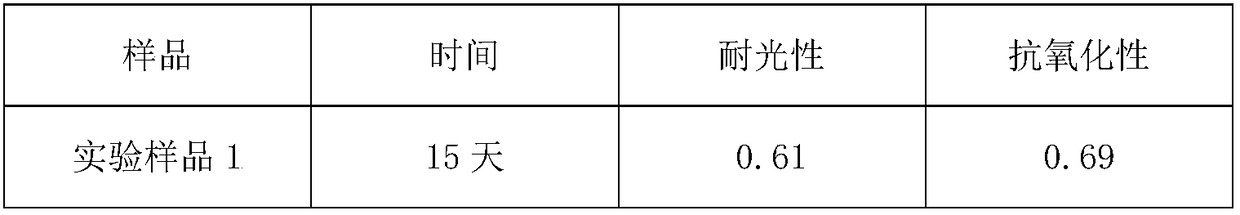

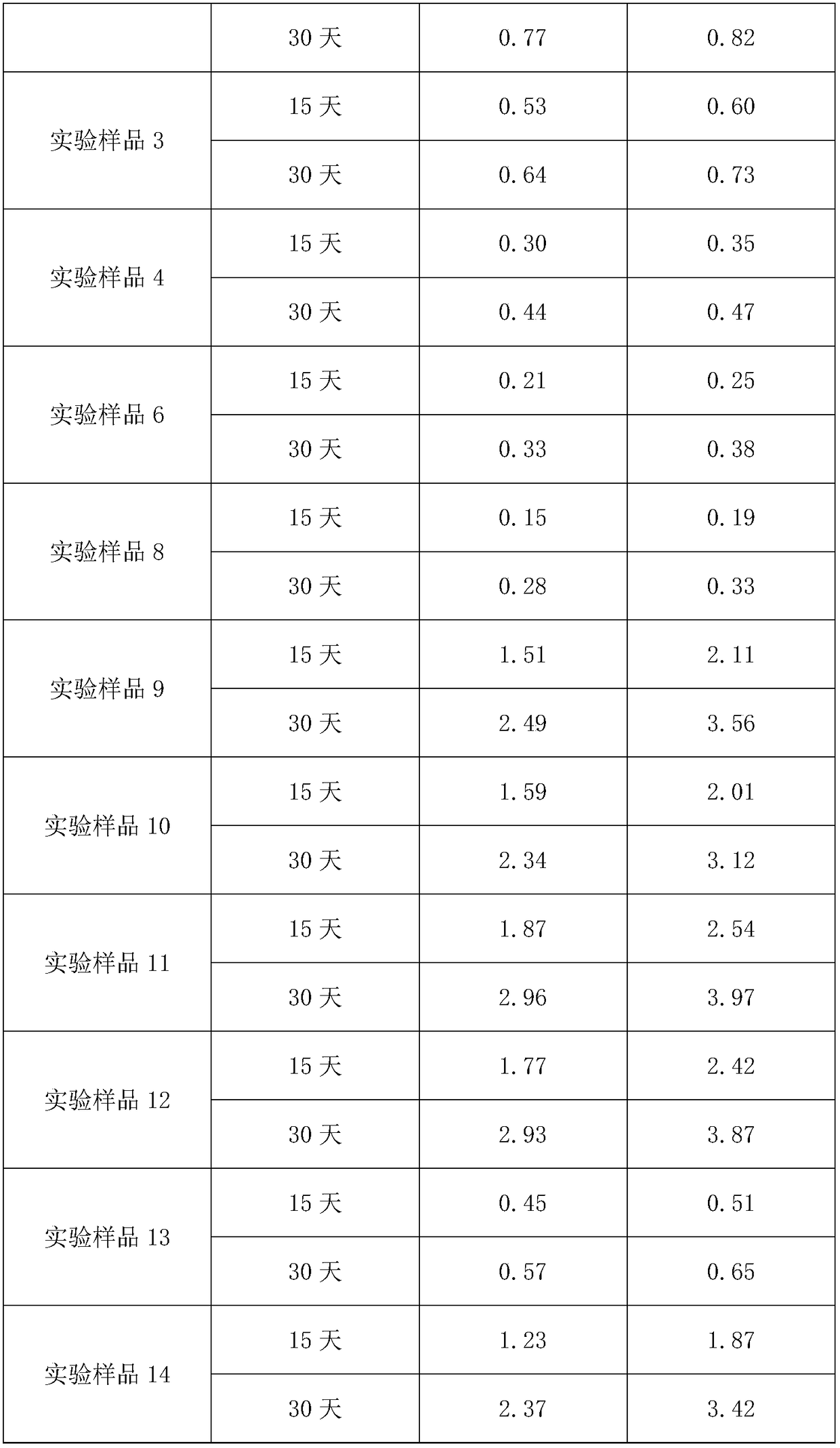

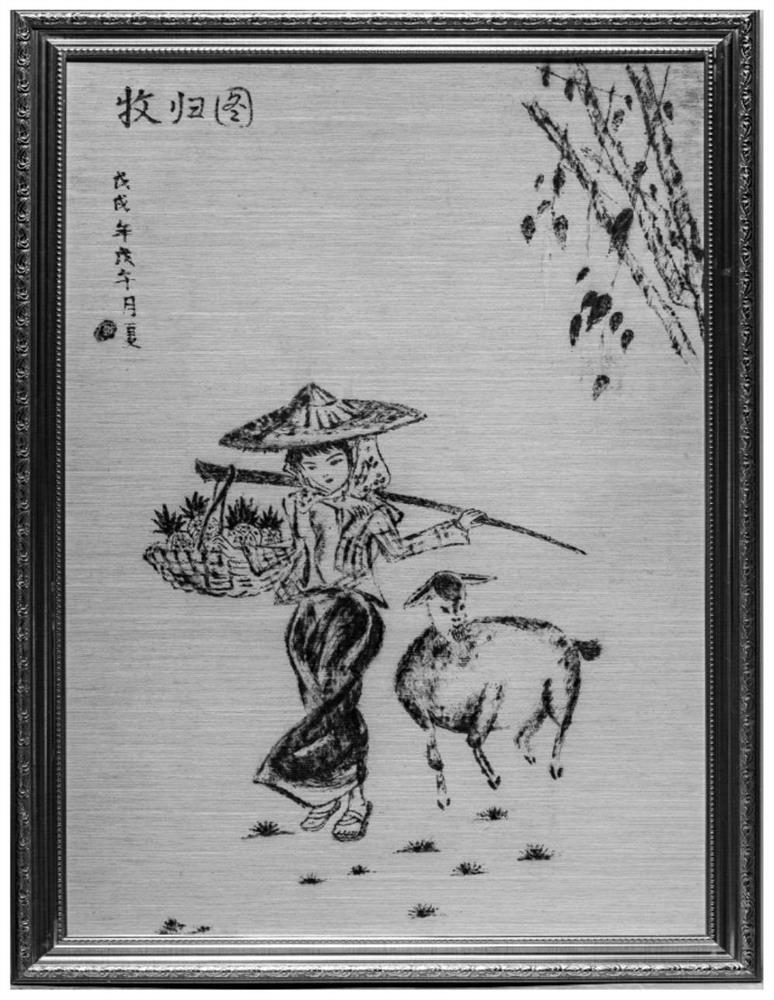

Peasant painting pigment and preparation method and use method thereof

InactiveCN109251594APure colorBright colorAmylose/amylopectin coatingsArtist's paintsAcetic acidLemon juice

The invention provides a peasant painting pigment and a preparation method thereof and a use method thereof, and particularly relates to the technical field of painting materials. The peasant paintingpigment comprises the following raw materials by weight: 400 to 500 parts of water, 80 to 120 parts of water-saturated n-butanol, 25 to 35 parts of cassava, 25 to 35 parts of glutinous rice, 25 to 35parts of construction glue, 5-15 parts of lime paste powder, 5 to 15 parts of gallnut ash, 5 to 15 parts of litsea cubeba carbon, 125 to 165 parts of lemon juice, 1 to 3 parts of ethyl acetate, and 0.5 to 1.5 parts of antioxidant 1010. The peasant painting pigment prepared by the method has bright color, high gloss, oxidation resistance, light resistance and environmental friendliness; the preparation method provided by the invention has high utilization rate of raw materials, high pigment purity, controllable process parameters and easy industrialization; drawn works using the peasant painting pigment are not easy to be damaged by worms, not easy to rot, and not easy to mold.

Owner:三江县连城兴农业科技有限公司

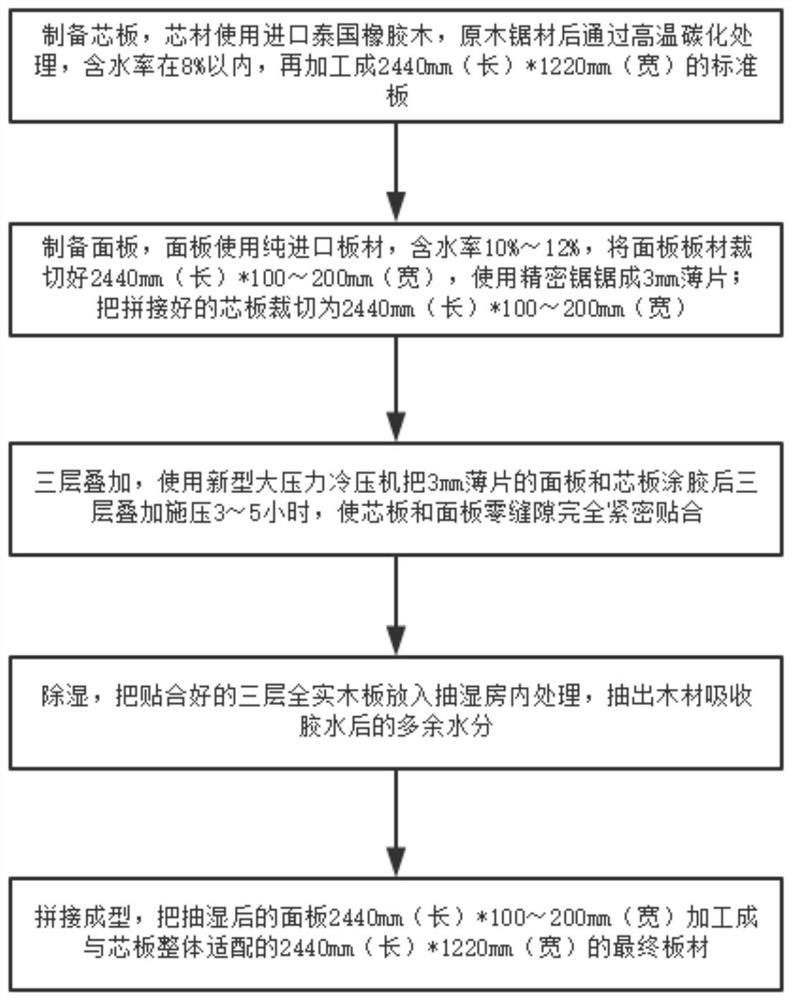

Environment-friendly waterproof and fireproof multilayer solid wood board and manufacturing process thereof

PendingCN111993503AAvoid deformationAvoid crackingWood treatment detailsWood veneer joiningSolid woodCarbonization

The invention discloses an environment-friendly waterproof and fireproof multilayer solid wood board and a manufacturing process thereof, relates to the field of processing and production of solid wood boards, and aims at avoiding material waste and improving deformation resistance, dust prevention, insect generation prevention and mildew prevention. The multilayer solid wood board comprises a core board and a panel, imported Thailand rubber wood is used as the core material of the core board, a pure imported board is used as the panel, the moisture content is 10%-12%, and the board with cleartexture and the best quality is selected; the manufacturing process specifically comprises the following steps that the core board is prepared, imported Thailand rubber wood is used as the core material, high-temperature carbonization treatment is conducted after log saw cutting, and then the log is spliced into a 2440 mm (length) * 1220 mm (width) standard board. According to the environment-friendly waterproof and fireproof multilayer solid wood board and the manufacturing process thereof, imported Thailand rubber wood is adopted as the core material, and high-temperature carbonization treatment is carried out after log sawing; the finally-prepared three-layer total solid wood board is not prone to deformation, cracking and expansion; and in addition, the board has the advantages of being low in water content and not prone to insect generation and mildewing.

Owner:郑凯

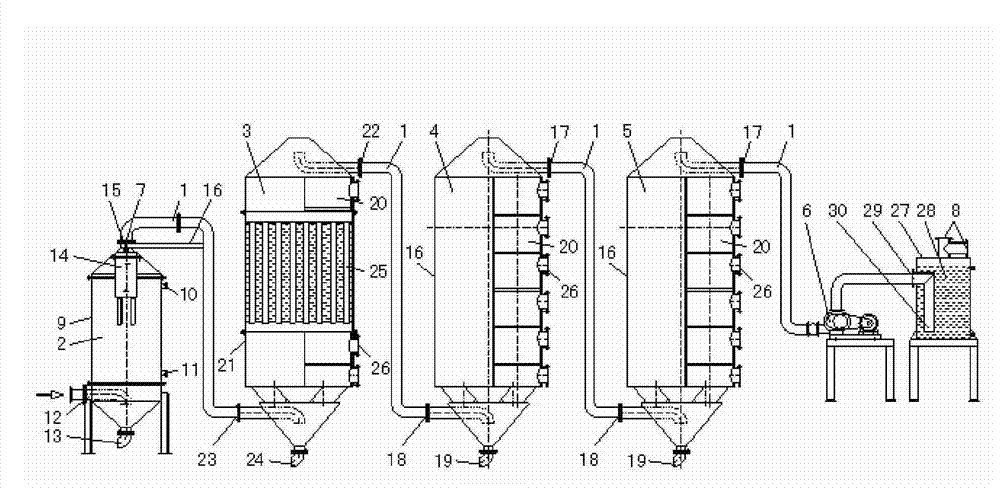

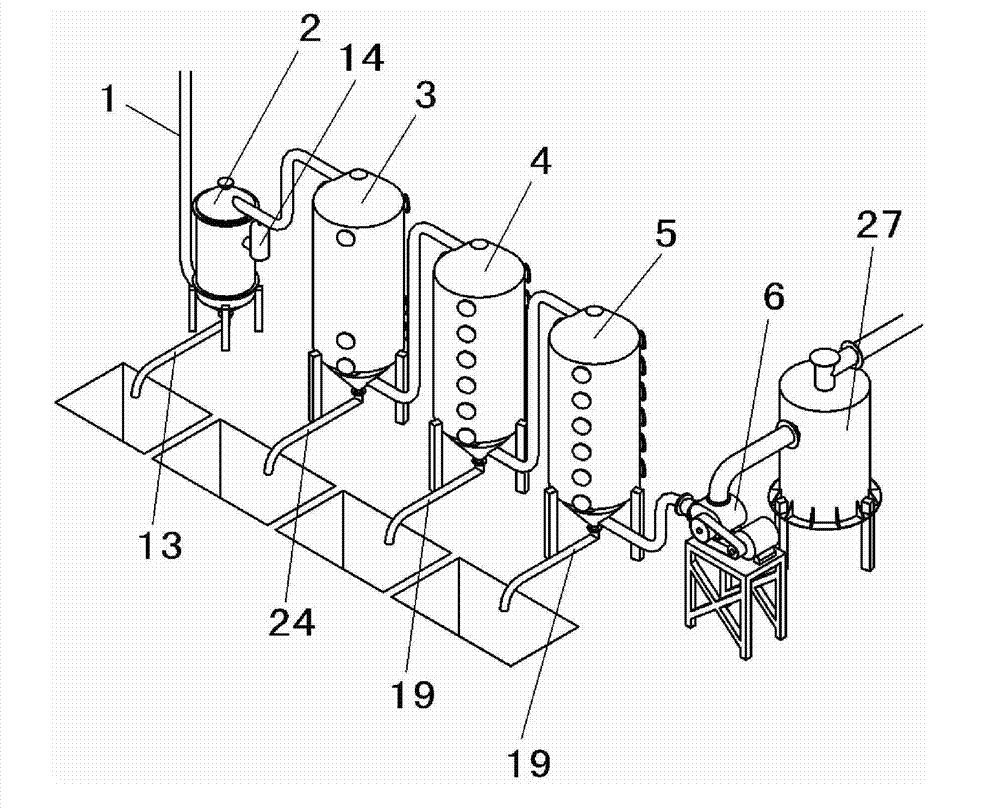

Method and device for collecting, separating, purifying and cleaning new energy by utilizing carbon making waste gas

InactiveCN101519607BWide range of usesPlay the role of antibacterial and sterilizingEnergy inputCombustible gas purificationElectricityNew energy

The invention discloses a method and a device for collecting, separating, purifying and cleaning new energy by utilizing carbon making waste gas. In the method, carbon making smoke gas sequentially passes through a waste heat boiler, a pyroligneous liquid separating device and two level woodtar separating devices so as to separate pyroligneous liquid and woodtar in the carbon making smoke gas and obtain purified combustible gas. The device comprises the waste heat boiler (2), the pyroligneous separating device (3), a one-level woodtar separating device (4), a two-level woodtar separating device (5), a blower (6) and a water block (27) which are sequentially connected through pipelines (1). The waste heat boiler (2) is provided with a smoke gas inlet (7), and the water block (27) is provided with a purified combustible gas inlet (8). The invention utilizes purified waste smoke gas produced in the carbon making process to generate electricity, and also extracts pyroligneous liquid and woodtar in the waste smoke gas as raw materials of other industries, thereby being an energy recycling industry chain system engineering, turning waste into treasure and reducing the energy consumption.

Owner:李观德

Method for manufacturing seat cushion with jute fibre

ActiveCN101172571BGood puffing effectImprove acupuncture effectUpholstery fillingFibre treatment to obtain bast fibrePectinaseAntibiosis

The invention relates to a manufacturing method of a seat cushion made of jute fiber. The method comprises the following steps: firstly, the soaking is performed to jute in compound enzyme water solution prepared by pectase and laccase, and the weight ratio of the compound enzyme water solution and the jute is 12 : 1 to 40 : 1; the pH value of the compound enzyme water solution is firstly adjusted into 4.0 to 6.5, and the compound enzyme water solution is warmed up to 35 to 65 DEG C, and the temperature is kept for 20 to 120 minutes; and then pH value of the compound enzyme water solution is adjusted to more than 8.0 and less than and equal to 9.5, and the compound enzyme water solution is kept for 20 to 120 minutes at 14 to 70 DEG C; then the enzyme inactivation process is performed to the jute processed through the compound enzyme; secondly, jute fiber after being degumed is mixed with chemical fiber, and carding, mesh placement and needling are performed to the chemical fiber; thirdly, the mixed fiber after being needled is thermally pressed and molded; fourthly, a sleeve body is coated. The seat cushion manufacuted by the invention is soft and comfortable, has no urtication feeling when being used by people, and has good antibiosis and anti-acarine performance.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

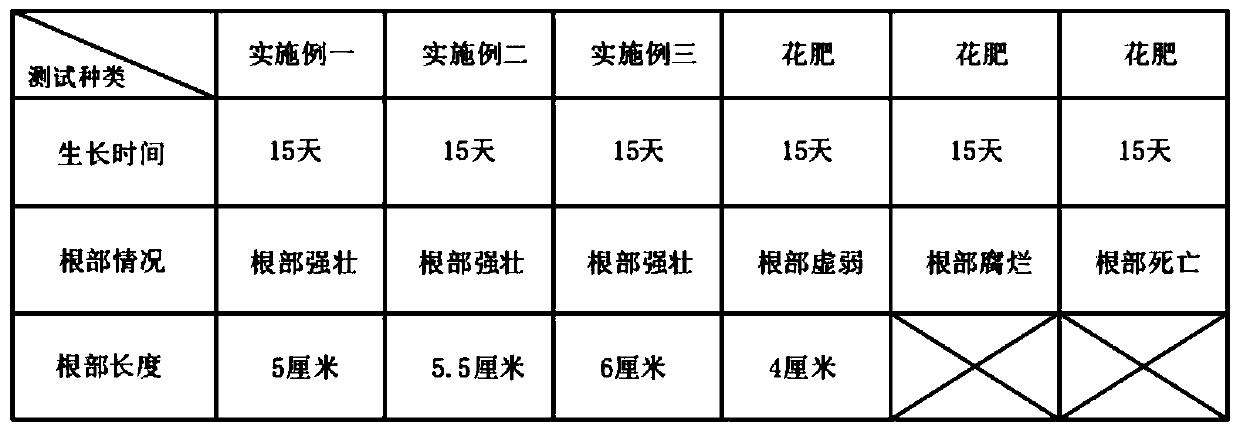

Amino acid water-soluble fertilizer

InactiveCN111559943AGood biodegradabilityGood sterilizationCalcareous fertilisersMagnesium fertilisersChemistryAgricultural crops

The invention discloses an amino acid water-soluble fertilizer. The amino acid water-soluble fertilizer is prepared from, by weight, 530 to 570 parts of free amino acids, 180 to 220 parts of chelatedcalcium, 17 to 23 parts of chelated boron, 26 to 35 parts of chitosan, 190 to 210 parts of wood acid liquid and 30 to 35 parts of humic acid. The water-soluble fertilizer provided by the invention canadjust the physiological function of crops, ensures that the root systems of the crops grow strongly, have thick leaves, are not prone to be suffering from diseases and expel insects, and is beneficial to improving the yield of the crops.

Owner:山东海岱绿洲生物工程有限公司

Method for manufacturing insole with jute fiber

ActiveCN100591234CEfficient removalWeaken joint forceInsolesFibre treatment to obtain bast fibrePectinaseFiber

A method for manufacturing insoles by jute fibers comprises treating jute fibers with the complex enzyme de-gelatinizing, wherein, the complex enzyme de-gelatinizing treatment uses complex enzyme aqueous solution which is formulated by pectase and laccase to provide the de-gelatinizing treatment to jutes, adjusting the pH value of the complex enzyme aqueous solution to be more than or equal to 4.0but less than 5.0 when the complex enzyme de-gelatinizing treatment is carried out, elevating the temperature to 35 DEG C to 65 DEG C for 20-120 minutes, and then adjusting the pH value of the solution to be 7.5 to 9.5, keeping the temperature under 40 DEG C to 70 DEG C for 20-120 minutes, enzyme-devitalizating the jutes which are treated by the complex enzyme, mixing the de-gelatinized jute fibers with the chemical fibers, carding, net-spreading, and needling the mixed fibers, hot-pressing the needled mixed fibers and molding. The insole manufactured by the method of the invention is very comfortable when in use, and is not urticant in feeling when in use, good in bacteria repellency, not easily wormy, and strong in air permeability, hygroscopicity, and moisture character.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

A kind of jujube milk tea formula and preparation method

The present invention discloses a red date milky tea recipe which comprises the following components: compound red date powder 40 parts and red dates 40 parts. The red dates are red date granules soaked and treated by sugar liquid. The present invention also provides a preparation method of the red date milky tea, which includes a red date granule preparation process and a compound red date powder preparation process. The compound red date powder consists of white granulated sugar, non-dairy creamer, milk powder, tea powder, red date powder, red date essence and milk essence. The red date granule preparation process includes the following steps: step 1, washing; step 2, sugar liquid preparation; step 3, red date granule sugaring; step 4, feed liquid preparation; step 5, filling; and step 6, sterilizing and cooling. The red date milky tea has a mellow and fragrant mouthfeel of the milky tea, at the same time also has a mouthfeel of the solid red date granules, and is rich in mouthfeel. The state, mouthfeel, and flavor of the red date granules can be coordinated and compatible with the brewed milky tea. Besides, the treated red date granules are easy to get moldy and breed worms, and the red date milky tea can be stored for a long time, solves the problem that the dry red dates can only be kept for a short shelf life, and have a shelf life up to 12 months.

Owner:南京喜之郎食品有限公司

An Embroidery Method of Flat Embroidery of Zhuang Nationality

ActiveCN104499220BImprove expressivenessImprove powerEmbroidering machines apparatusEngineeringPaper sample

The invention discloses an embroidering method of a Zhuang-nationality plain embroidery, belonging to the technical field of embroideries. The embroidering method comprises the following steps of A, pasting all silk fabrics with colors corresponding to those of a pattern onto a fabric shell; B, drawing the pattern on white paper, shearing all segments, then, correspondingly pasting all the segments of a paper sample on the fabric shell prepared in the step A, and respectively shearing to obtain embroidered pieces; C, embroidering on the embroidered pieces prepared in the step B; and D, splicing the embroidered pieces embroidered in the step C according to the pattern to form a complete view of picture, and covering the edge of the picture by using silk fabrics with corresponding colors to obtain the Zhuang-nationality plain embroidery. By using the embroidering method, the problems of poor third dimension and reality sense as well as expression and rendering insufficiency in an embroidery can be solved.

Owner:颍上鑫鸿纺织科技有限公司

Natural plant braided carpet and its manufacturing method

InactiveCN1274268CGood flexibilityExpand freelyCane mechanical workingWood working apparatusPliabilityEngineering

A carpet for decorating floor or wall is braided with wooden material in conjunction of bamboo, bast, herb, cotton, or papper. Its making technology is also disclosed. Its advantages are high flexibility, light weight, smooth surface and long service life.

Owner:许赞有

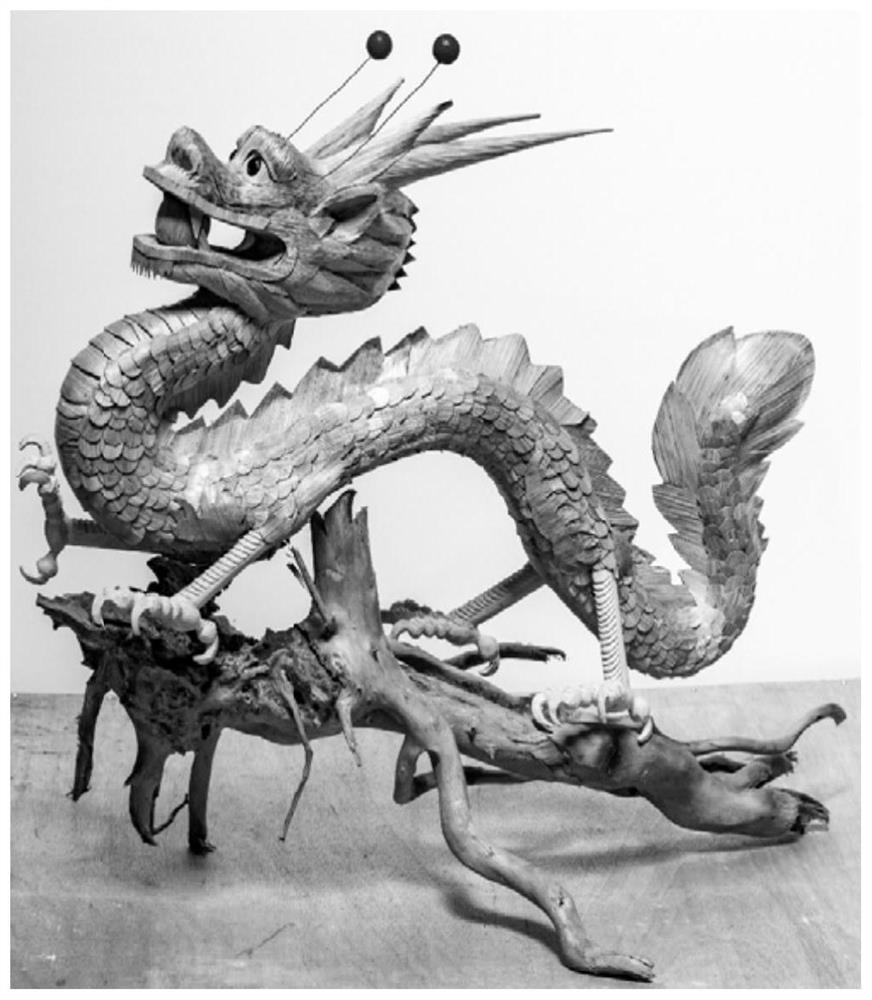

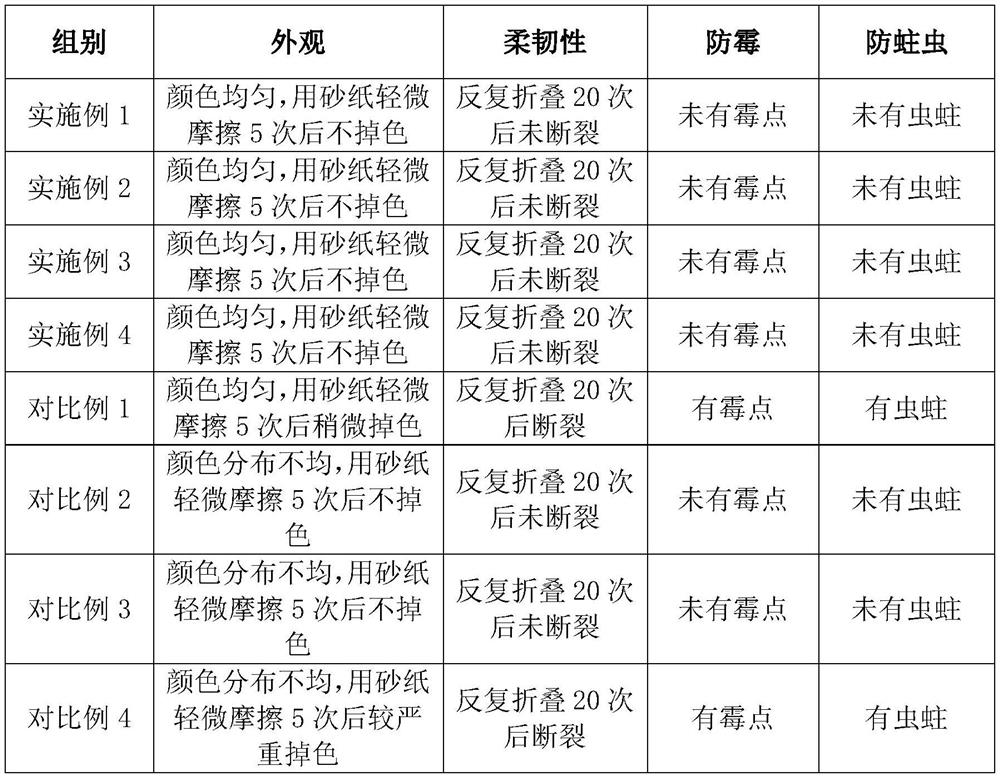

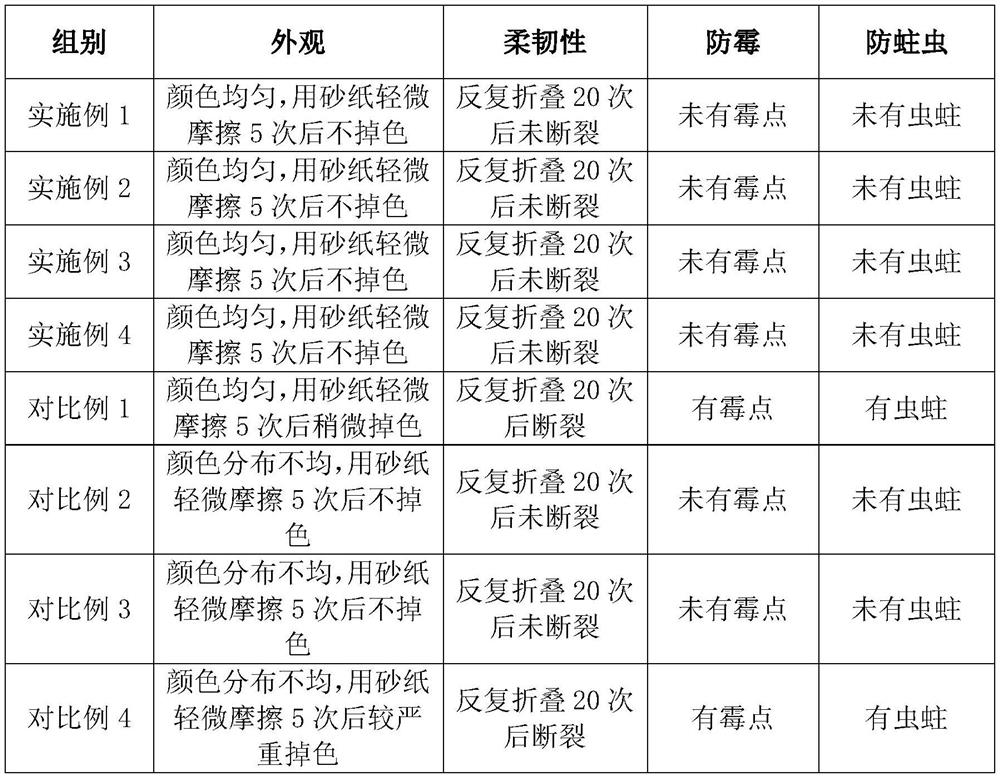

Manufacturing process of bamboo shell artware

ActiveCN111791333AMildew proofMoth proofWood treatment detailsSpecial ornamental structuresPulp and paper industryIndustrial engineering

The invention discloses a manufacturing process of bamboo shell artware. The artware is manufactured through the procedures that pretreatment is carried out, specifically, cooking, bleaching, dyeing and grinding are carried out; and then cutting is carried out according to the peculiar texture of a bamboo shell, and pasting and forming are carried. The manufactured artware is not prone to occur mildewing and insect breeding, uniform in color, not prone to fade, long in storage time and extremely high in ornamental and collection value.

Owner:陈亮

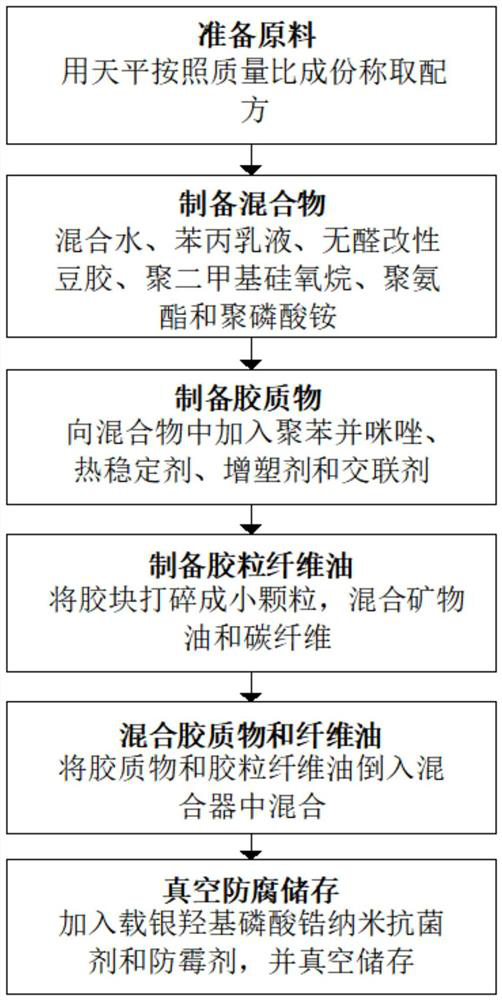

Preparation method of high-temperature-resistant geothermal composite floor glue

InactiveCN111849389AAvoid failureGuaranteed bonding effectNon-macromolecular adhesive additivesProtein adhesivesFiberSpontaneous combustion

The invention discloses a preparation method of high-temperature-resistant geothermal composite floor glue. The preparation method comprises the following steps of: preparing raw materials, preparinga mixture, preparing a colloidal substance, preparing colloidal particle fiber oil, mixing the colloidal substance and the fiber oil, and carrying out vacuum anti-corrosion storage. Polydimethylsiloxane, polyurethane and ammonium polyphosphate are added into styrene-acrylic emulsion and formaldehyde-free modified soybean glue to serve as main agents, the heat-resistant performance and the flame-retardant performance are effectively improved, the glue can resist a high temperature of 300 DEG C, spontaneous combustion is avoided, the glue is prevented from falling off and losing efficacy, the bonding performance on the floor is ensured; the plasticizing effect is improved through a plasticizer; a photochemical curing effect is generated through a cross-linking agent, the curing performance of the floor glue is good, and the floor glue can be compounded more tightly and is not prone to damp damage; meanwhile, by adding carbon fibers and glue particles, the flexibility of the floor glue isbetter, the elasticity of a composite floor is optimized, and the feet feel more comfortable; and through added negative ion powder, negative ions are released to the outside, and health is better facilitated.

Owner:来安县扬子地板有限公司

Method for producing handicraft processing paper using recycled fiber

ActiveCN106835796BImprove physical strengthHigh strengthPaper recyclingReinforcing agents additionFiberRegenerating fibers

Owner:SHANYING INT HLDG CO LTD

Tailor's chalk for production of outdoor clothing

InactiveCN108660814ADoes not affect the appearance of clothingEnvironmentally friendly ingredientsDyeing processParaffin oilsStearic acid

The invention discloses a tailor's chalk for the production of outdoor clothing. The tailor's chalk comprises the following raw materials by weight: 6-9 parts of palmatic acid, 3-7 parts of salicylicacid, 2-8 parts of paraffin, 5-10 parts of stearic acid, 3-5 parts of lauryl sodium sulfate, 2-3 parts of camphor, 1-2 parts of color developing agent, 30-50 parts of nerolin, 5-9 parts of zinc oxide,3-5 parts of color hiding agent, and 1-5 parts of aminopeptidase. The tailor's chalk has the beneficial effects that: (1) the ingredients are environmentally friendly, the cost is low, and the tailor's chalk is not easily damaged by worms, and can be stored for long; (2) after being used on the garment material, the tailor's chalk dyes easily and also fades relatively easily, and the appearance of the garment is not affected.

Owner:ANHUI YINGSHIBO TEXTILE DEV CO LTD

Ceramsite suitable for planting of succulent plants

InactiveCN110128106AGood air permeabilityPromote rootingGrowth substratesCulture mediaMaifan StoneCellulose

The invention discloses a ceramsite suitable for planting of succulent plants. The ceramsite comprises the following components, in percentages by weight: 76%-84% of kaolin, 1%-9% of maifan stone, 1%-9% of volcanic stone, 2%-4% of cellulose and 7% of water. The ceramsite prepared in the invention is mainly applied to the planting of the succulent plants, the ceramsite has excellent gas permeability, does not store excess water, and can quickly promote the effects of rooting and root strengthening of the succulent plants and prevent roots of the succulent plants from being rotten, and the succulent plants planted by using the ceramsite do not easily get sick or have worms; in addition, the main components of the ceramsite are the kaolin, the maifan stone and the volcanic stone, the raw materials contain a plurality of microelements, so that the effect of improving growth vigour of the succulent plants can be achieved; and at the same time the ceramsite is clean and hygienic, does not produce odor, and can bring out bright colors of the succulent plants.

Owner:王帅

Weaving bamboo cane oil-prevention treatment method

InactiveCN106363724AAvoid pollutionExtended service lifeReed/straw treatmentWood impregnation detailsPotassiumChloride

The invention relates to the technical field of weaving processes, in particular to a weaving bamboo cane oil-prevention treatment method. The weaving bamboo cane oil-prevention treatment method includes the following steps of bamboo sorting, bamboo hitting, bamboo washing, peeling, primary soaking, secondary soaking and drying. The primary soaking is conducted in a soak solution for 5-6 hours, and the soak solution for the primary soaking comprises, by weight, 3-5 parts of perfluorocarboxylic acid, 1-3 parts of phenol, 1-2 parts of disodium hydrogen phosphate, 1-3 parts of ammonium hydroxide and 100-200 parts of water; and then bamboo is fished out and subjected to the secondary soaking, a soak solution for the secondary soaking comprises, by weight, 1-2 parts of chlorendic acid, 3-4 parts of gold potassium chloride, 2-3 parts of caustic soda, 1-2 parts of polyvinyl pyrrolidone and 100-150 parts of water, the temperature in the secondary soaking is 60-80 DEG C, and the bamboo is fished out and aired after the two times of soaking. The weaving bamboo cane oil-prevention treatment method can prevent grease pollution, bamboo canes are not prone to generation of insects and are good in flame retardant efficiency and high in strength, and the service life of woven products is prolonged.

Owner:ANHUI MEIJING ARTS & CRAFTS CO LTD

Method for manufacturing mattress by using jute fiber

ActiveCN101168432BEfficient removalWeaken joint forceUpholstery fillingFibre treatment to obtain bast fibreAntibiosisPectinase

Owner:JIANGSU REDBUD DYEING TECH CO LTD

A kind of embroidery method of Zhuang cloth patchwork

ActiveCN104499218BImprove expressivenessImprove powerFibre treatmentEmbroidering machines apparatusComputer scienceSilk fabric

Owner:苏州盛泽科技创业园发展有限公司

A kind of manufacturing process of bamboo clothes handicraft

ActiveCN111791333BMildew proofMoth proofWood treatment detailsSpecial ornamental structuresPulp and paper industryMaterials science

The invention discloses a manufacturing process of a bamboo clothing handicraft. The handicraft is produced through pretreatment, cooking, bleaching, dyeing, polishing, and then cutting and pasting according to the unique texture of the bamboo clothes. The handicrafts are not easy to mold, insects, uniform in color, not easy to fade, and have a long storage time. , of great ornamental and collection value.

Owner:陈亮

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com