Preparation method of high-temperature-resistant geothermal composite floor glue

A composite floor, high temperature resistant technology, applied in the field of floor adhesive manufacturing, can solve the problems of insufficient curing performance of floor adhesive, affecting the composite sealing performance of the floor, and damage to the floor due to moisture ingress, so as to optimize the antibacterial and anti-corrosion performance, avoid shedding failure, and optimize the elastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

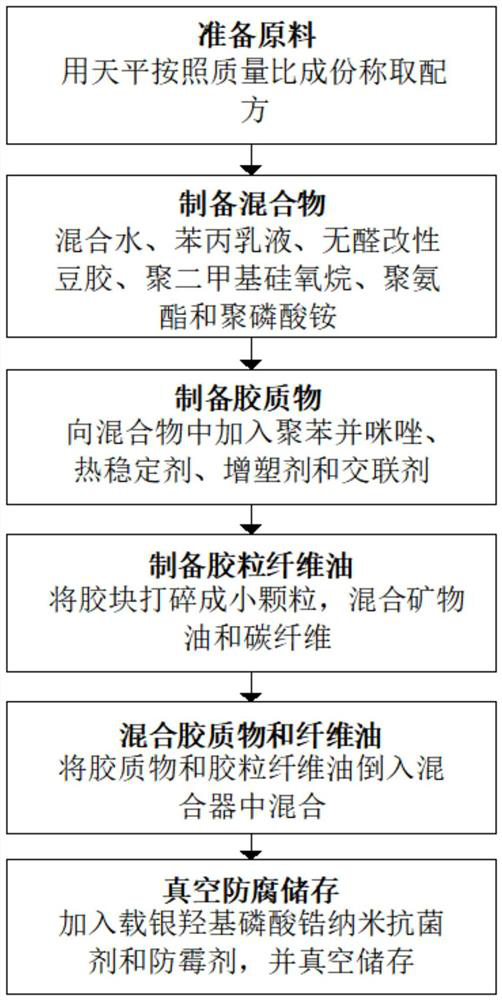

[0028] according to figure 1 As shown, this embodiment provides a preparation method of high temperature resistant geothermal composite floor glue, comprising the following steps:

[0029] Step 1: Prepare raw materials

[0030] Use a balance to weigh the ingredients according to the mass ratio: 50 parts of water, 60 parts of styrene-acrylic emulsion, 80 parts of aldehyde-free modified bean gum, 30 parts of polydimethylsiloxane, 15 parts of polyurethane, 10 parts of ammonium polyphosphate, 8 parts Parts of negative ion powder, 5 parts of polybenzimidazole, 8 parts of carbon fiber, 8 parts of heat stabilizer, 5 parts of plasticizer, 7 parts of mineral oil, 5 parts of crosslinking agent, 4 parts of silver-loaded zirconium hydroxyphosphate nano-antibacterial agent, 0.1 Part of wetting agent, 6 parts of rubber block, 1 part of dispersant, 0.3 part of antifoaming agent and 0.03 part of antifungal agent; Wherein, described thermal stabilizer is ferric oxide, and described plasticize...

Embodiment 2

[0042] according to figure 1 As shown, this embodiment provides a preparation method of high temperature resistant geothermal composite floor glue, comprising the following steps:

[0043] Step 1: Prepare raw materials

[0044] Use a balance to weigh the formula according to the mass ratio of ingredients: 55 parts of water, 65 parts of styrene-acrylic emulsion, 90 parts of aldehyde-free modified bean gum, 33 parts of polydimethylsiloxane, 18 parts of polyurethane, 12 parts of ammonium polyphosphate, 9 parts Parts of negative ion powder, 6 parts of polybenzimidazole, 9 parts of carbon fiber, 9 parts of heat stabilizer, 6 parts of plasticizer, 10 parts of mineral oil, 6 parts of crosslinking agent, 5 parts of silver-loaded zirconium hydroxyphosphate nano-antibacterial agent, 0.15 Part of wetting agent, 8 parts of rubber block, 1.5 parts of dispersant, 0.35 part of antifoaming agent and 0.04 part of antifungal agent; Wherein, described thermal stabilizer is ferric oxide, and des...

Embodiment 3

[0056] according to figure 1 As shown, this embodiment provides a preparation method of high temperature resistant geothermal composite floor glue, comprising the following steps:

[0057] Step 1: Prepare raw materials

[0058] Use a balance to weigh the formula according to the mass ratio of the ingredients: 60 parts of water, 68 parts of styrene-acrylic emulsion, 100 parts of aldehyde-free modified bean gum, 35 parts of polydimethylsiloxane, 20 parts of polyurethane, 15 parts of ammonium polyphosphate, 10 parts Parts of negative ion powder, 7 parts of polybenzimidazole, 10 parts of carbon fiber, 10 parts of heat stabilizer, 7 parts of plasticizer, 15 parts of mineral oil, 7 parts of crosslinking agent, 7 parts of silver-loaded zirconium hydroxyphosphate nano-antibacterial agent, 0.2 Part of wetting agent, 12 parts of rubber block, 2 parts of dispersant, 0.4 part of antifoaming agent and 0.05 part of antifungal agent; Wherein, described thermal stabilizer is ferric oxide, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com