Paper-plastic corrugated plate and fabricating method thereof

A corrugated board and paper-plastic technology, applied in the field of paper-plastic corrugated board, can solve the problems of difficult natural decomposition of plastic sheets, no elastic function, no environmental protection, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

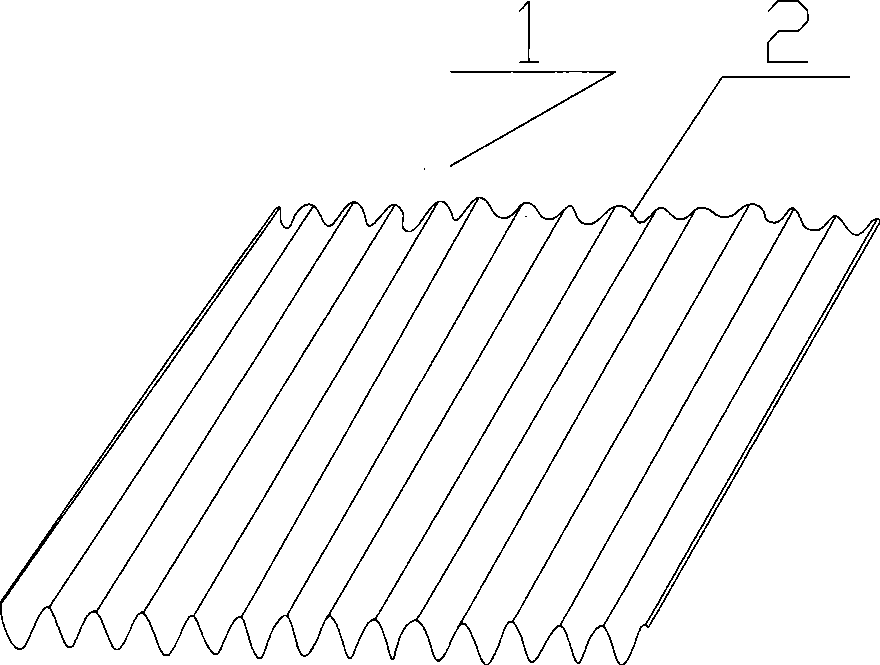

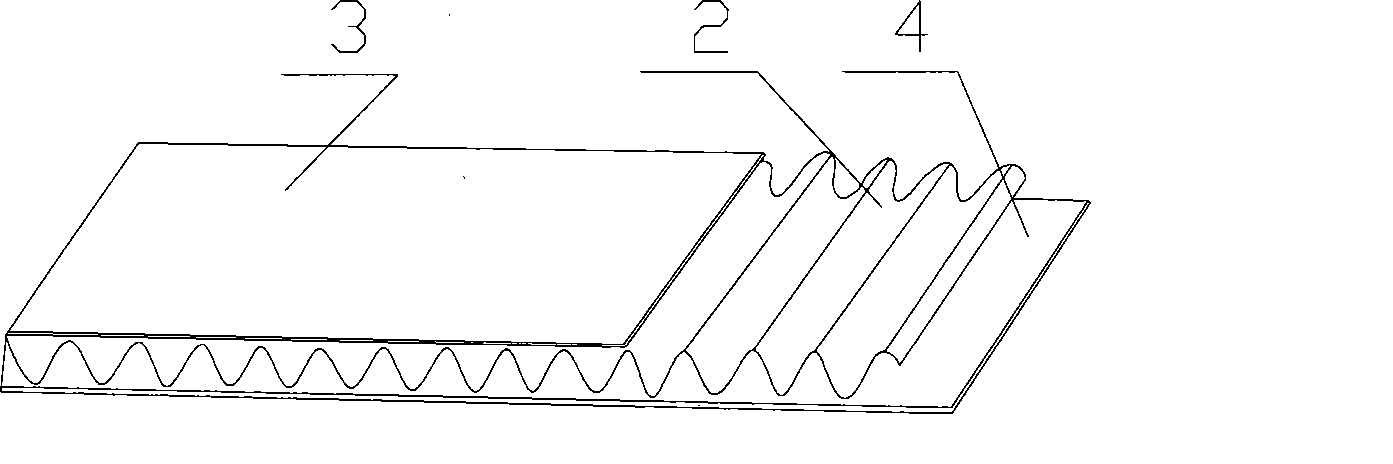

[0014] Embodiment 1: with reference to attached figure 1 with 2 . The paper-plastic corrugated board adopts calcium-plastic paper 1 to make elastic calcium-plastic corrugated paper. A piece of elastic calcium-plastic corrugated paper is provided with face paper 4 and inner paper 3 on both sides. The cross-section is a rectangular concave-convex surface or the cross-section is a wavy concave-convex surface or a regular semicircular concave-convex surface. The thickness range of the elastic calcium-plastic corrugated paper 2 is greater than or equal to 0.1mm and less than 2.0mm. The production of the calcium-plastic paper 1 is a prior art, here No narrative. The face paper and the inner paper are kraft paper, cardboard paper or white board paper. The main material of the elastic calcium-plastic corrugated paper 2 is PE, PP, PVC, PS, and the auxiliary material is calcium carbonate or calcium sulfite. .

Embodiment 2

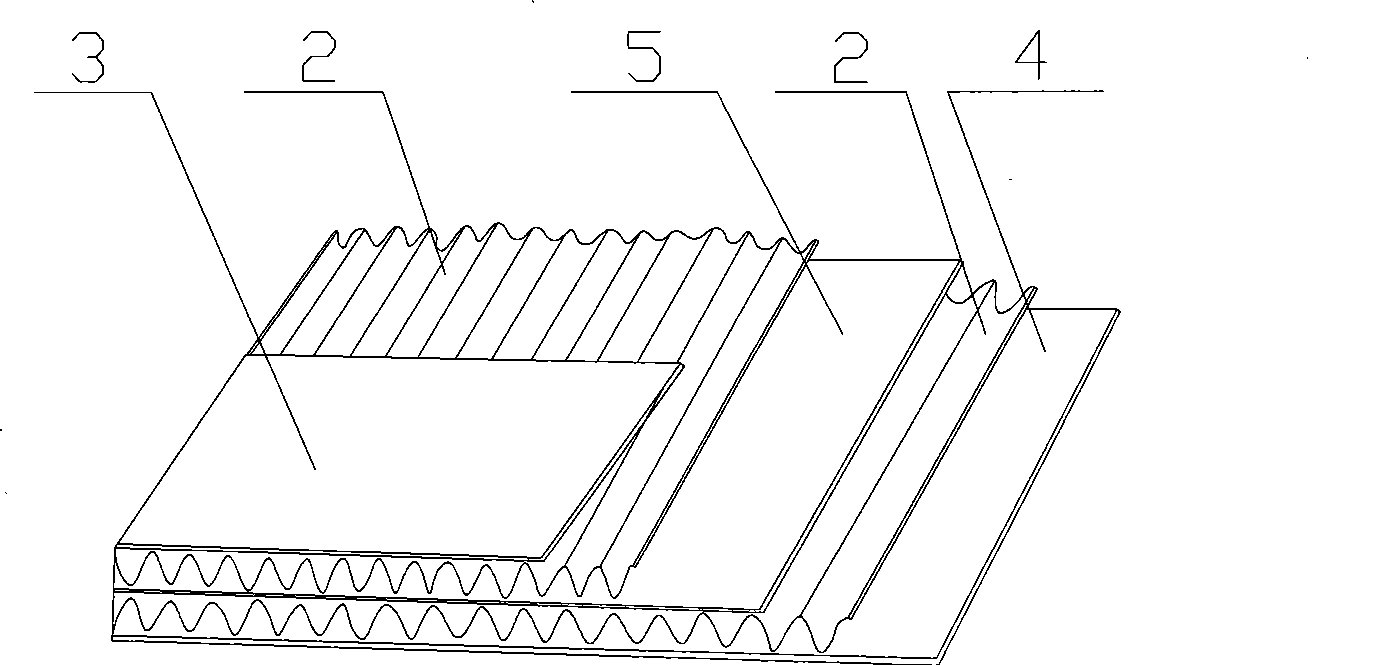

[0015] Embodiment 2: with reference to attached figure 1 , 3 ~5. On the basis of Example 1, the concave-convex surfaces between more than one piece of elastic calcium-plastic corrugated paper 2 are superimposed and bonded to each other through the inner paper 3 or the face paper 4, and the exposed concave-convex surface and the surface of the multi-layer paper-plastic corrugated board are stacked and bonded. Paper 4 or lining paper 3 glued.

Embodiment 3

[0016] Embodiment 3: On the basis of Embodiment 1 or 2, the elastic calcium-plastic corrugated paper 2 has a rectangular concave-convex surface or a wavy concave-convex surface or a regular semicircular concave-convex surface. The thickness of the elastic calcium-plastic corrugated paper 2 is 0.1mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com