Automatic centering alignment device and method for assembling torque sensor

A torque sensor and automatic centering technology, which is applied in the direction of instruments, measuring devices, torque measurement, etc., can solve the problems of difficult control of product centering consistency, insufficient reliability of centering results, and low work efficiency, and achieve Automatic/manual selection, beneficial to operation, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

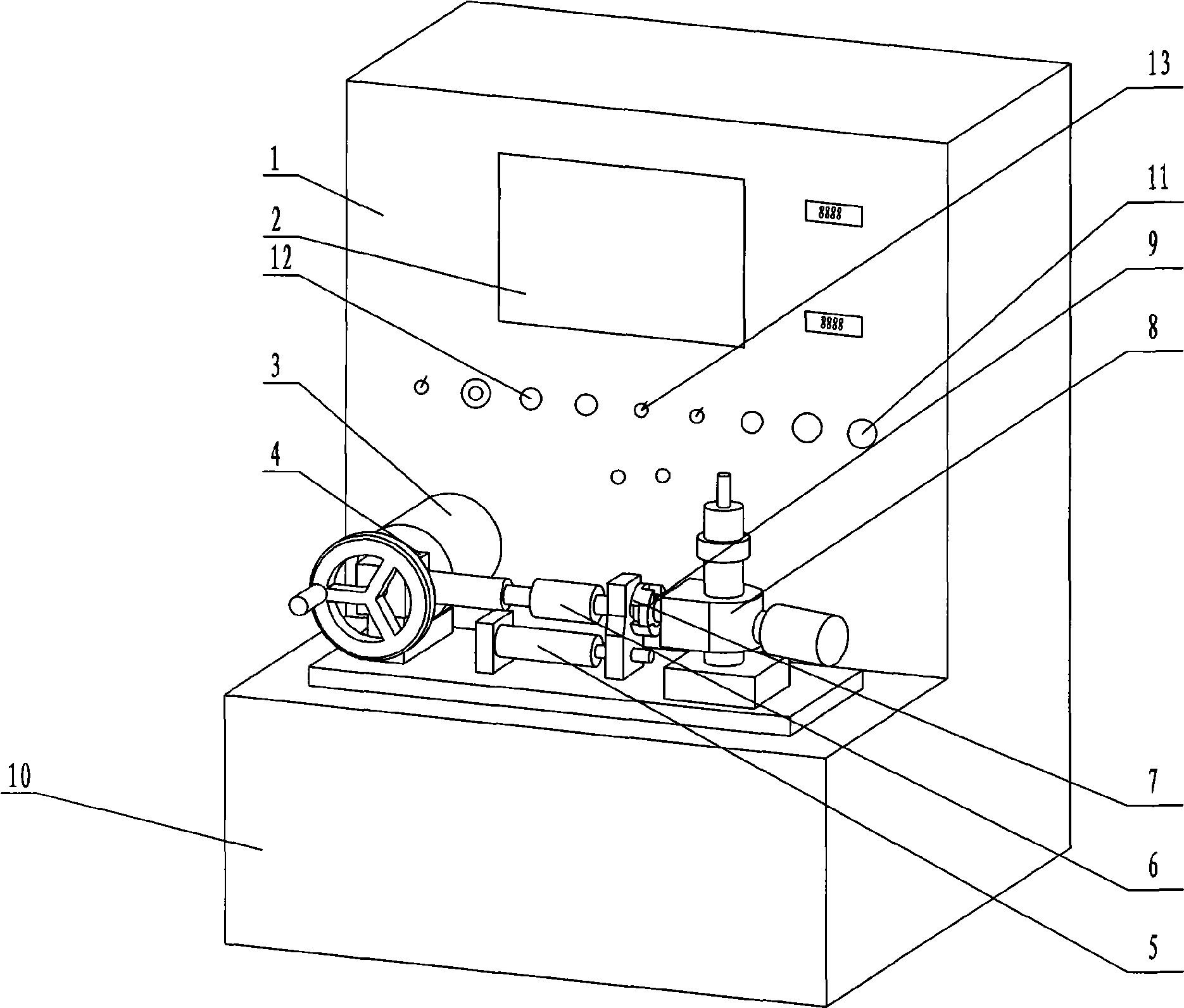

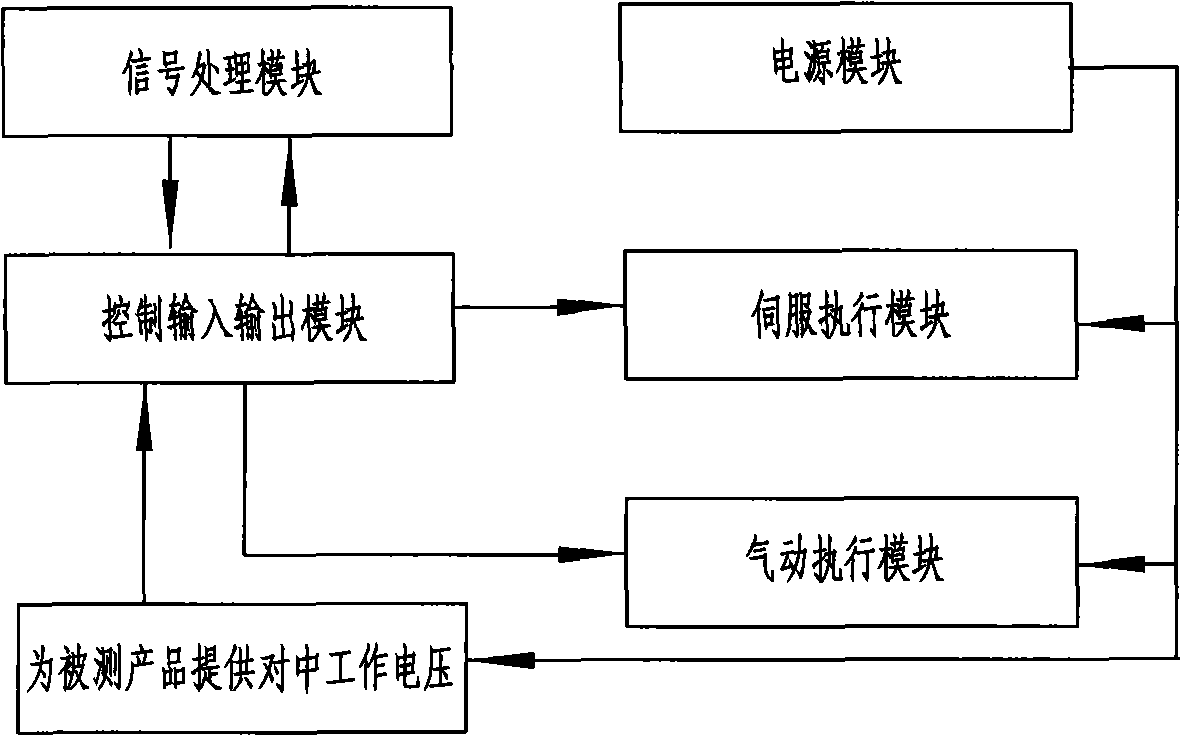

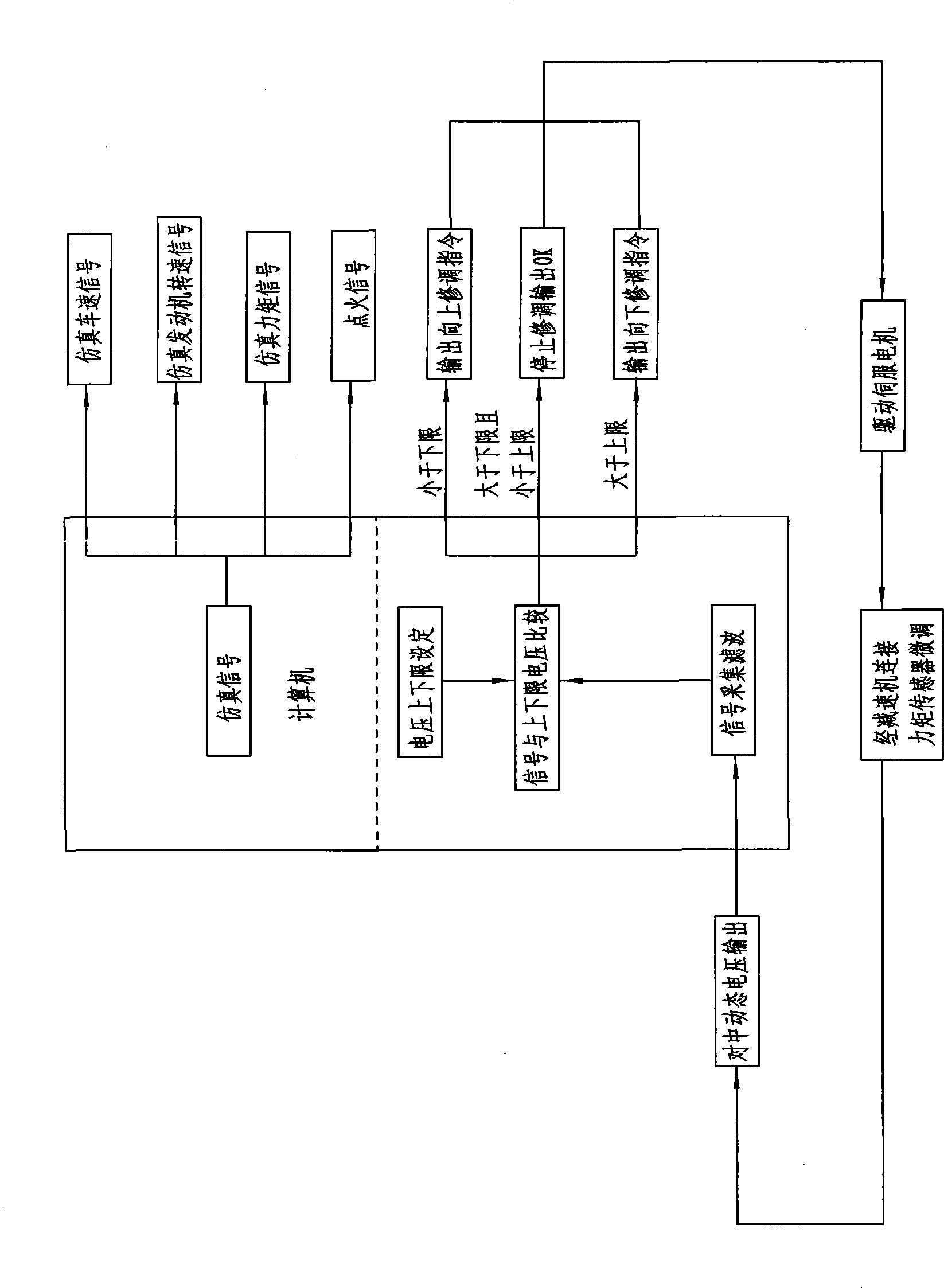

[0024] Such as figure 1 As shown, the automatic centering and debugging equipment for assembling torque sensors of the present invention includes a workbench 10 and a control cabinet 1 . The control cabinet 1 is provided with a computer start button 11 , an automatic centering start button 12 and an automatic centering / resetting switch 13 . The workbench 10 is the support of the whole equipment, and the workbench 10 is provided with a servo motor 3, a reducer 4, a coupling 6, a cylinder 5, a fixture 7, and an EPS assembly 8. The EPS assembly 8 includes a steering shaft, a steering column, a torque sensor 9, a controller, and an electric motor. The moment sensor 9 wherein uses the moment sensor of DFL-04 type. The control cabinet 1 is provided with a computer 2 and a control center. The computer 2 is provided with a signal processing module, and the control center includes a power supply module, a servo execution module, a pneumatic execution module, and a control input and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com