Reflection plate and light emitting device

A technology for light-emitting devices and reflectors, applied in reflectors, lighting devices, components of lighting devices, etc., to achieve the effects of excellent heat resistance and excellent reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

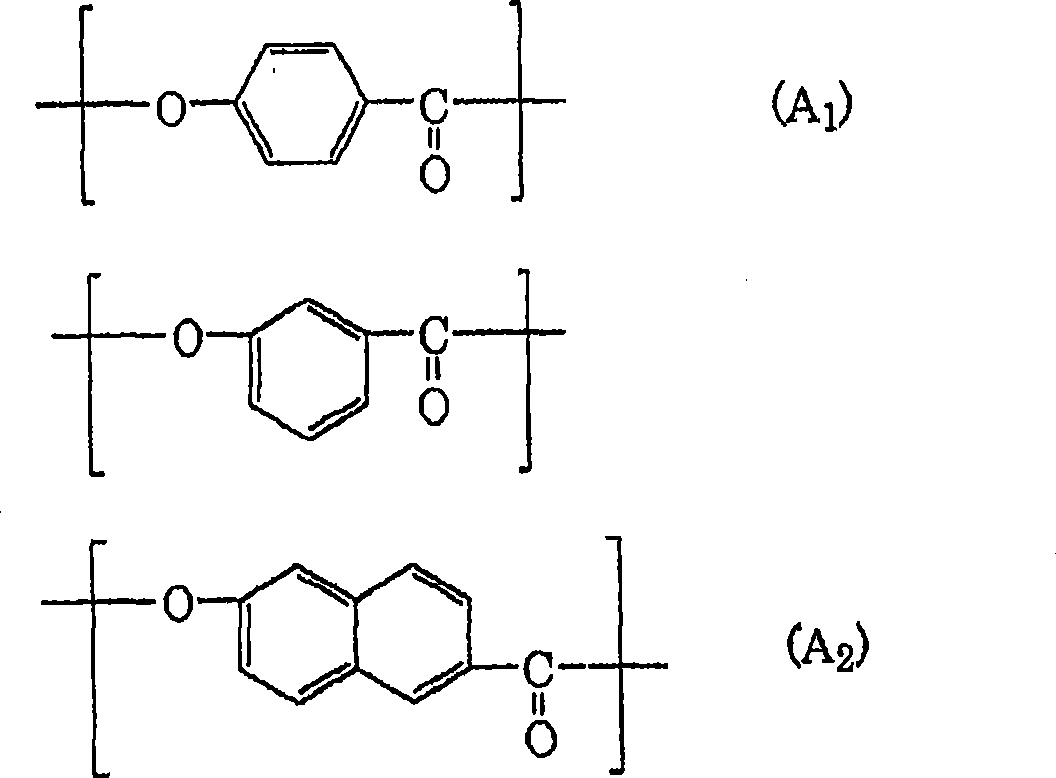

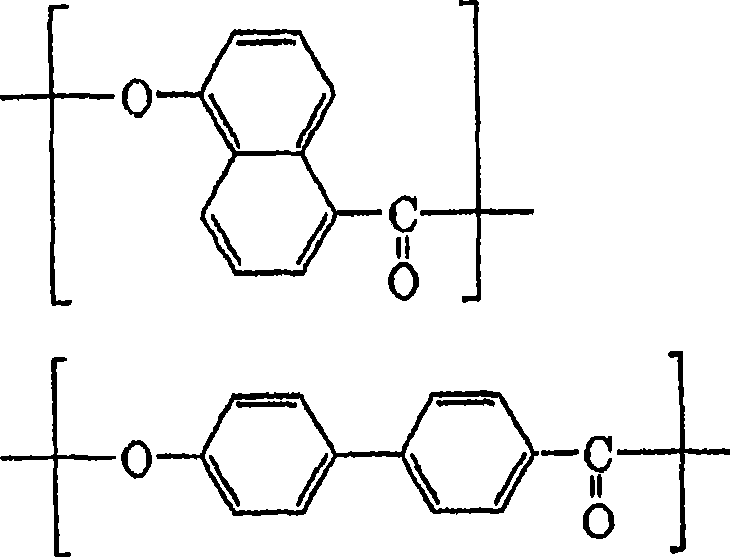

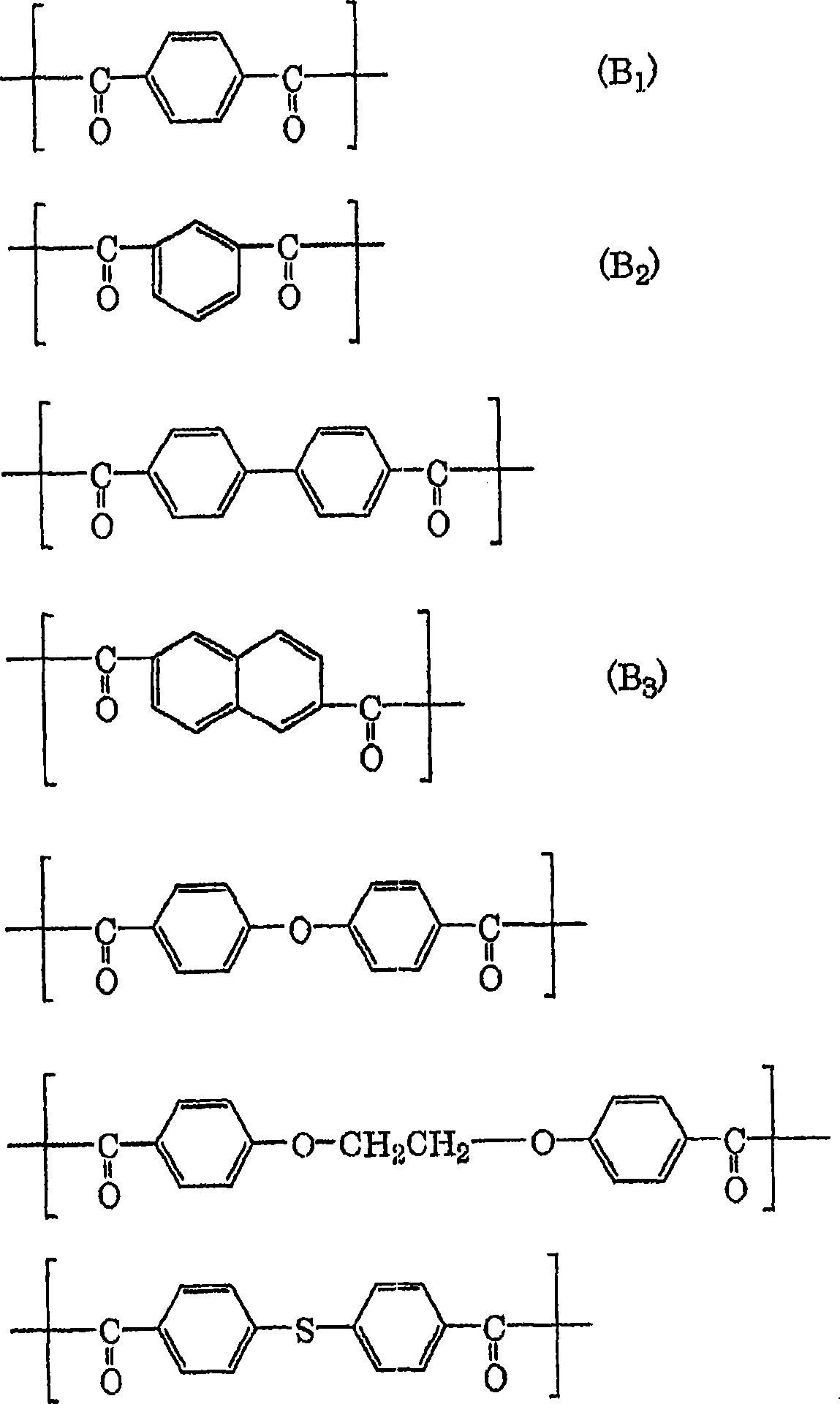

Method used

Image

Examples

Embodiment 1

[0131] In a reactor equipped with a stirrer, torque meter, nitrogen inlet tube, thermometer and reflux condenser, 994.5 g (7.2 mol) of p-hydroxybenzoic acid, 446.9 g (2.4 mol) of 4,4'-bis Hydroxybiphenyl, 299 g (1.8 mol) of terephthalic acid, 99.7 g (0.6 mol) of isophthalic acid and 1347.6 g (13.2 mol) of acetic anhydride, and 0.2 g of 1-methylimidazole were added. After the atmosphere in the reactor was sufficiently replaced with nitrogen and heated to 150°C in 30 minutes under nitrogen flow, the mixture was refluxed for 1 hour while maintaining the temperature.

[0132] 1-Methylimidazole (0.9 g) was added and, thereafter, heated to 320° C. over 2 hours and 50 minutes while distilling off acetic acid and unreacted acetic anhydride produced as by-products. After the reaction was complete, ie after confirming the increase in torque, a prepolymer was obtained.

[0133] The formed prepolymer was cooled to room temperature, ground by a coarse grinder, heated from room temperature...

Embodiment 2-5 and comparative Embodiment 1-6

[0136] The liquid crystal polyester 1 used in Example 1 was mixed with various fillers at the mixing ratio shown in Table 1 to obtain a resin composition. Reflection plate samples have been obtained in the same manner as in Example 1, and various measurements have been performed. The results are shown in Table 1 and Table 2.

[0137] Table 1

[0138]

[0139] Table 2

[0140]

[0141] As shown in Table 1, compared with the sample without the silica-based filler (component (C)) added thereto (see Comparative Examples 1-5), all components (A)-(C ) samples showed higher reflectivity (see Examples 1-5). It was found that although a sample with high reflectance could be obtained by using a large amount of titanium dioxide filler (see Comparative Example 2), the sample had sharply degraded heat resistance when soldered. In the samples containing glass-made fillers (glass beads) used in place of silica-based fillers (see Comparative Examples 3-5), the samples had a higher p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com