Low migration polyolefin composition

A composition and polyolefin technology, applied in the field of polyolefin composition, can solve the problem of harmful migration behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0059] The polyolefin (A) used as matrix polymer in all examples is bimodal high density polyethylene produced in the Borealis Borstar plant (cf. EP 1095102 B1, Example 1), and 32 x 3mm (outer diameter x wall thickness) tubing.

[0060] In the inventive examples and comparative examples, the following components were used.

[0061] Compound (B):

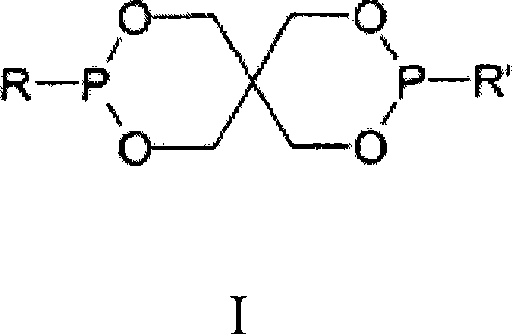

[0062] - Bis(2,4-dicumylphenyl)pentaerythritol-diphosphite (Doverphos S-9228) purchased from Dover Chemical Corp. TM )

[0063] - Tris(2,4-di-tert-butylphenyl) phosphite (Irgafos 168) purchased from Ciba Specialty Chemical TM )

[0064] Phenolic compounds (C):

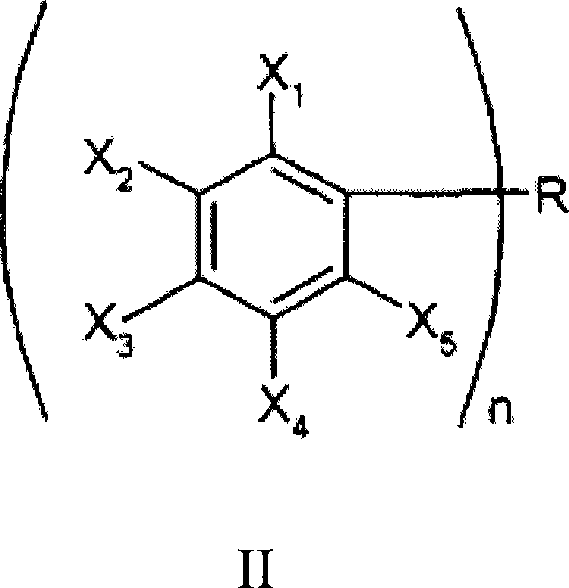

[0065] -Pentaerythritol-tetrakis(3-(3',5'-di-tert-butyl-4-hydroxyphenyl)propionate (Irganox 1010) purchased from Ciba Specialty Chemicals Co., Ltd. TM ),

[0066] - 1,3,5-trimethyl-2,4,6-tris(3,5-di-tert-butyl-4-hydroxyphenyl)benzene (Ethanox 330 TM ),or

[0067] -Ethylene glycol bis(3,3-bis(4'-hydroxy-3'-tert-butylphenyl (phaneyl))butyrate (Hostanox O3) purchased fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com