Process for synthesizing bisphenol A by utilizing cation resin

A technology of cation exchange and resin synthesis, applied in the production process of bisphenol A, can solve the problems of high failure rate of equipment, insufficient guarantee of device operation reliability, long process flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

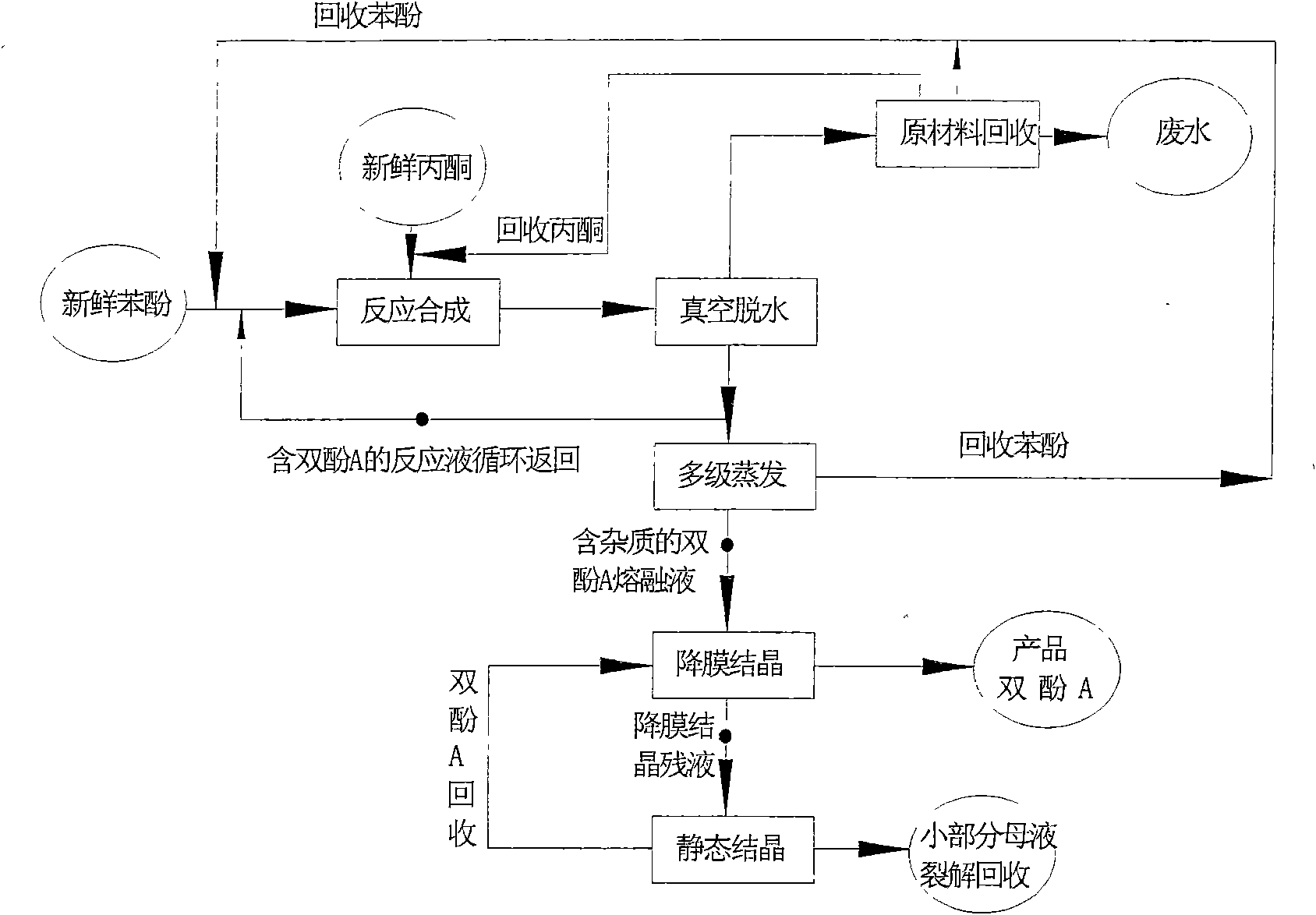

[0010] A kind of technique for synthesizing bisphenol A with cation exchange resin, comprises the following steps: after phenol, acetone is passed through the reaction liquid after the reactor that cation exchange resin is equipped with, send into vacuum dehydration to remove acetone, water and part of phenol, Then send the mixture containing phenol, bisphenol A and impurities into a multi-stage vacuum evaporation system to remove phenol, and then send the mixture of bisphenol A containing impurities into the falling film crystallizer, through multiple crystallization, partial melting, During the entire melting cycle process, high-purity bisphenol A melt is separated, and the separated impurity liquid is sent to a static crystallizer, and further recovered to obtain a recovered liquid with higher purity of bisphenol A, which is sent to falling film crystallization for recovery, from static crystallization The impurity liquid discharged from the tank is further recovered through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com