Deodorized radish red pigment and deodorization method

A technology of radish red and red pigments, which is applied in the field of deodorization of natural pigments of cruciferous plants, to achieve the effect of improving purity and color value, high purity and high color value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

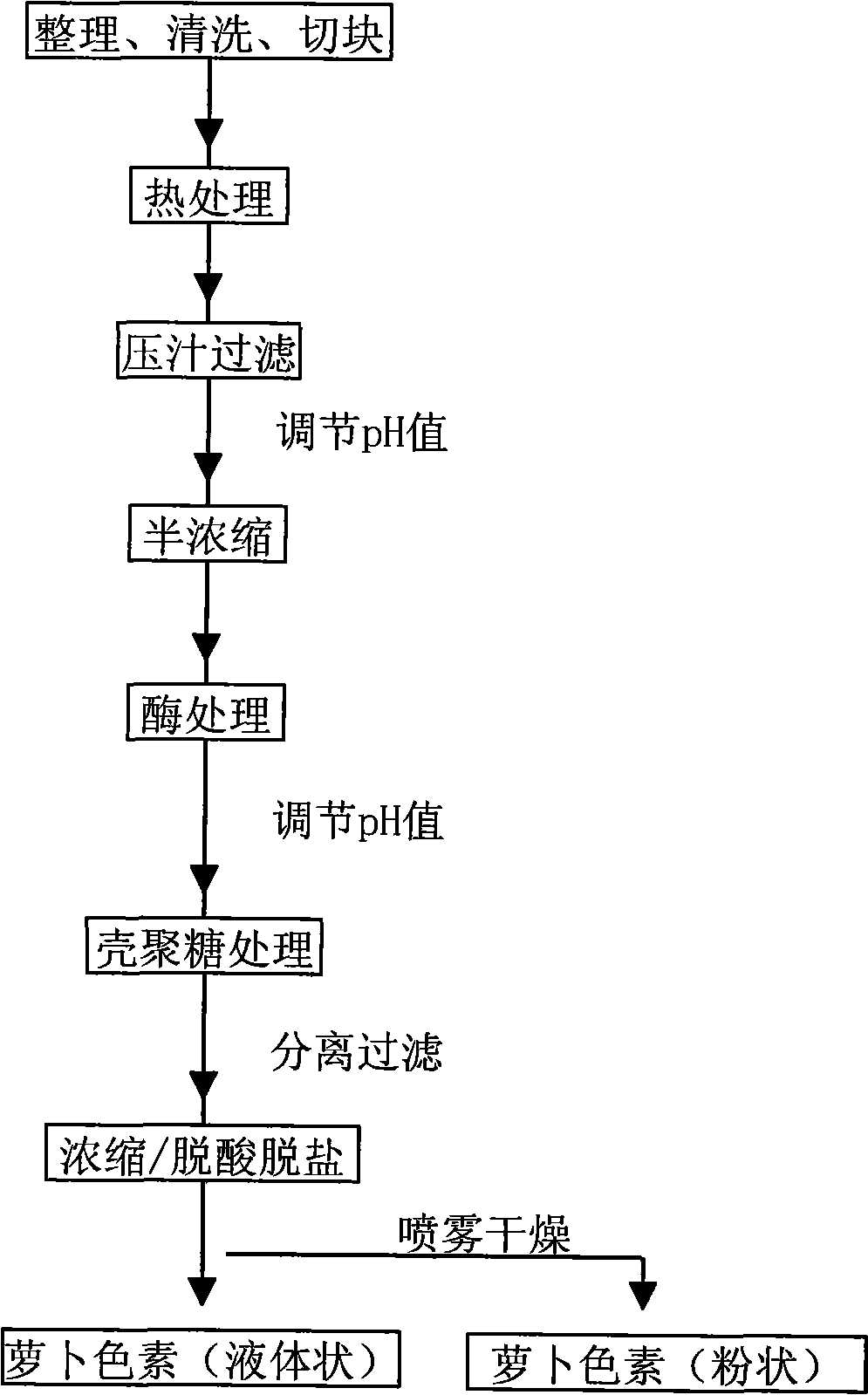

Method used

Image

Examples

Embodiment 1

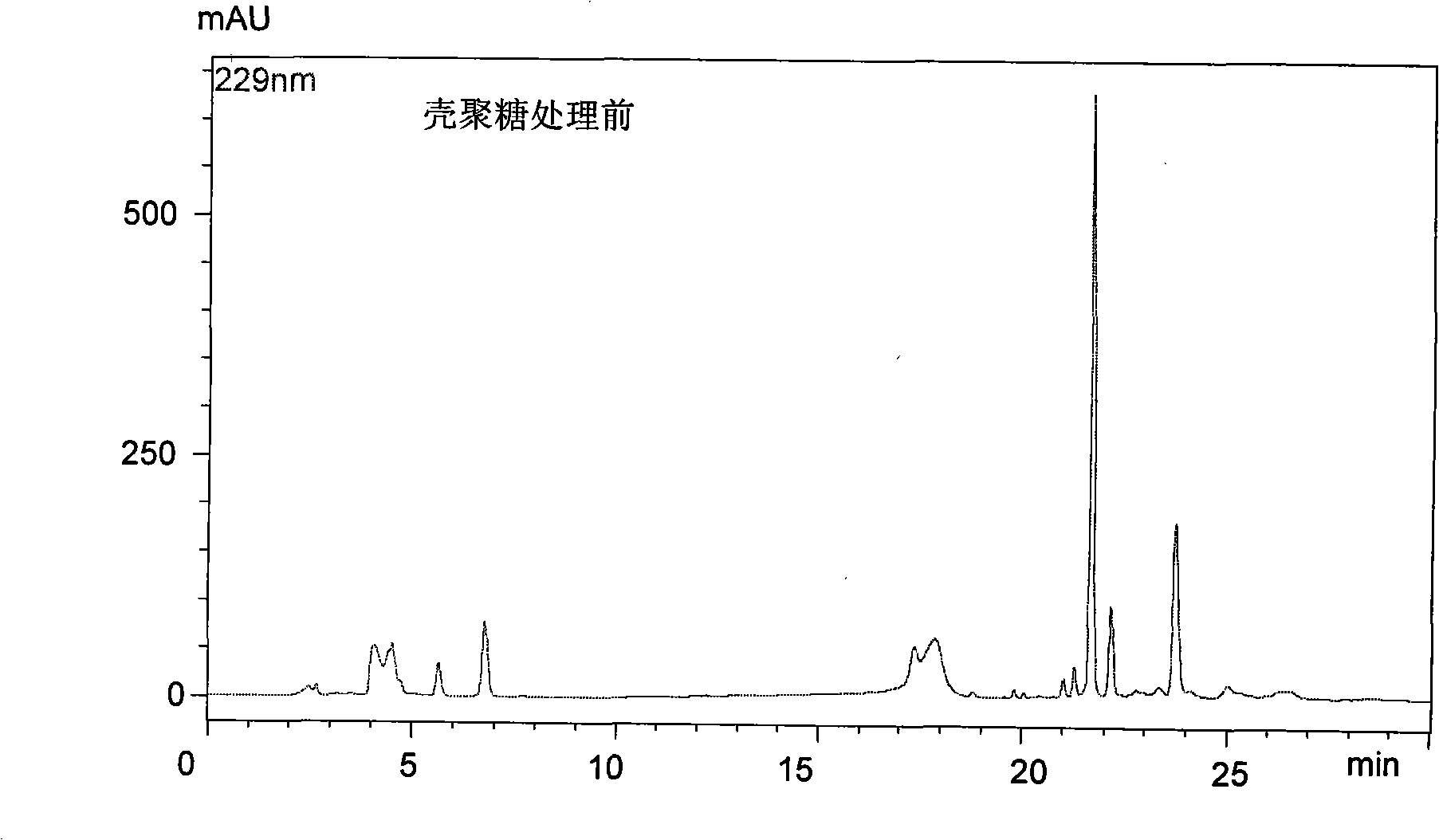

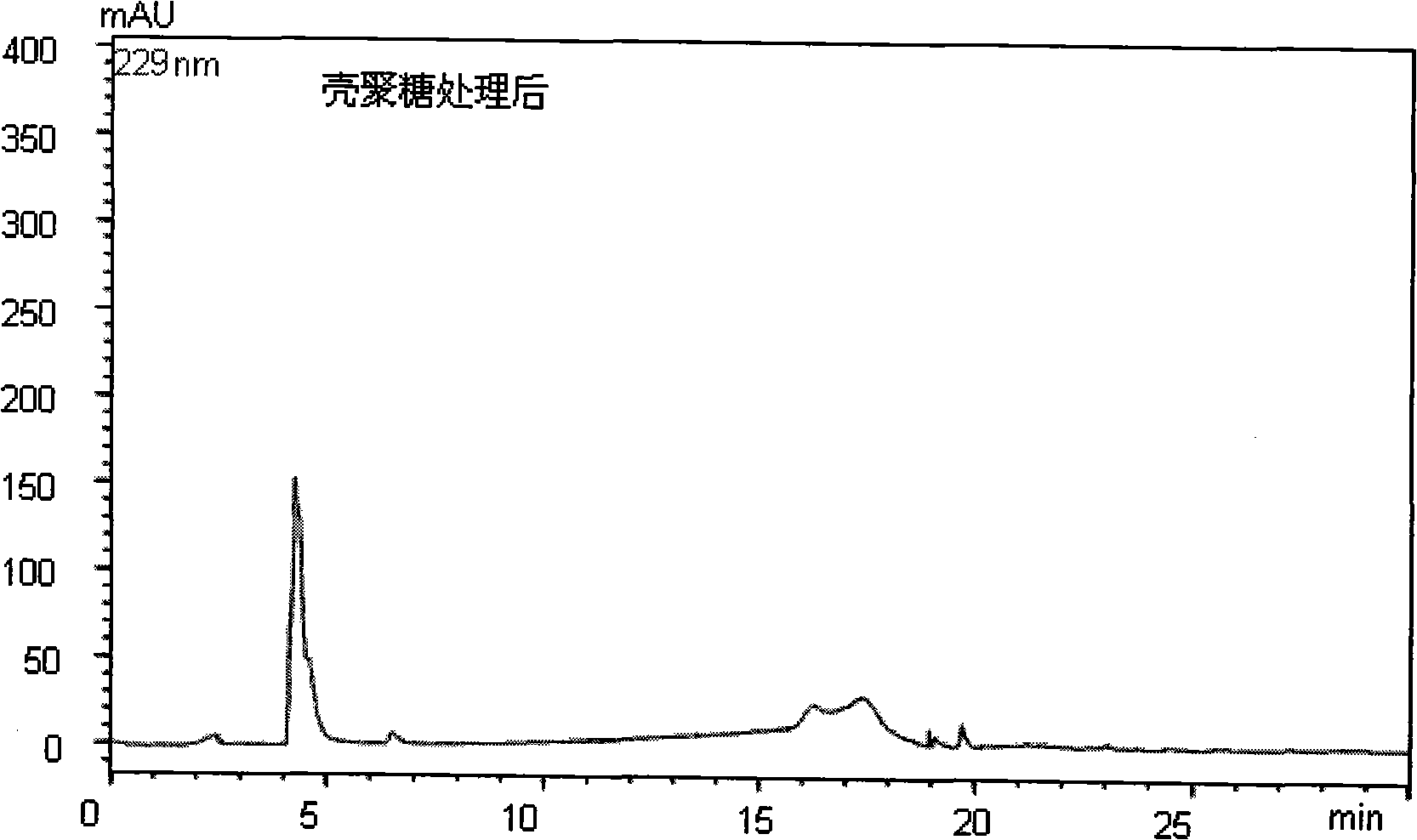

[0034] Choose 5 kg of red-skinned red-hearted radish with deep red color and tight and uniform texture, wash, arrange, cut into pieces, quickly put it into boiling water and fill it with steam to quickly heat to boiling for 5-10 minutes. The radish pieces after the boiling water treatment are squeezed together with the boiling water to obtain 5 L of filtrate and 1.5 kg of filter residue, and the radish residue is subjected to enzymatic hydrolysis treatment, and an acidic aqueous solution is added to the radish residue according to a solid-liquid ratio of 1:1 (m:v). Adjust the pH to 3.5, add pectinase (20000U / g) at the same time, the dosage is 0.2g / kg radish residue weight, temperature 45°C, stir at low speed for 2 to 4 hours, centrifuge to collect the extract, enzymolysis is also soaking The process of extracting the red pigment. Pectinase can hydrolyze plant tissue to facilitate the extraction of pigments, and at the same time remove most of the pectin and improve clarity. C...

Embodiment 2

[0036] Select 5 kg of local green-skinned and red-heart radishes in Jiangsu Province that are round and even, and obtain 5 L of radish stock juice through the pretreatment steps of Example 1 above. Then adjust the pH of the red radish juice to 3.5, then carry out the enzymatic hydrolysis treatment as in Example 1. Carry out deodorization and clarification treatment to the radish red stock solution, adjust the pH value of the filtrate to 4, add 2% (w / w) chitosan (the degree of deacetylation is 90%), stir at a slow speed for 2 minutes, let stand for 3 hours, and filter Obtain dark red clear, tasteless, transparent radish extract.

Embodiment 3

[0038] Obtain the pigment stoste of red-skinned red-heart radish according to the processing method of embodiment 1, then carry out deodorizing clarification process, adjust pH value to 3.5, add the chitosan (90% deodorized radish raw material) of 0.5% and 5% (w / w radish raw material) respectively degree of acetylation), stirred at a slow speed for 2 minutes and then allowed to stand for 3 hours. See Table 1 for specific clarification and deodorization conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com