No-pollution internal-wall concrete water tank made of HDPE boards

A non-polluting, concrete technology, used in water supply installations, general water supply conservation, and configuration of water supply pools, etc., can solve the problems of corrosion of stainless steel materials, polluted water quality of water tanks, and water quality that cannot be directly consumed, and achieve good mechanical and water quality. Hygienic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

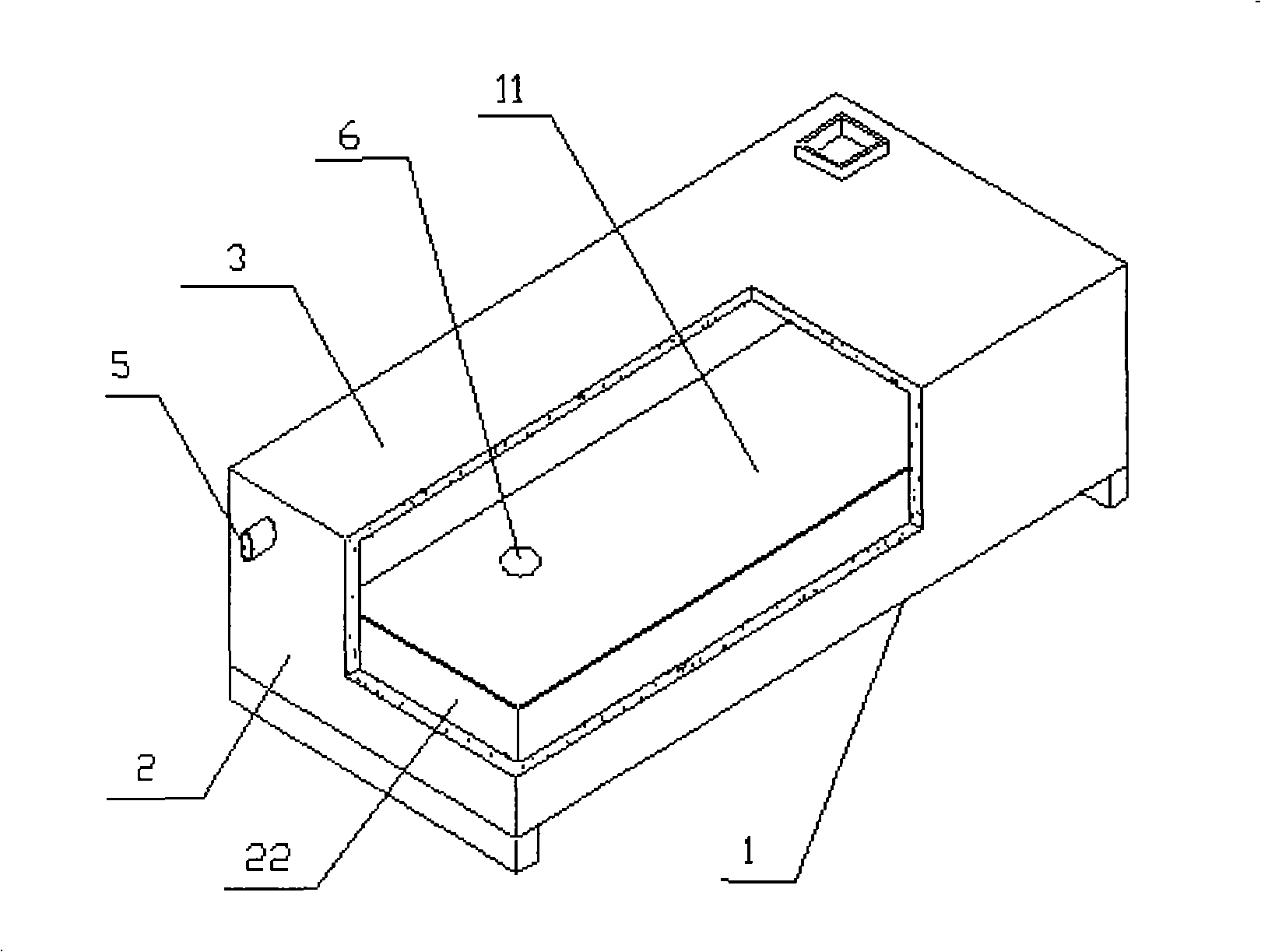

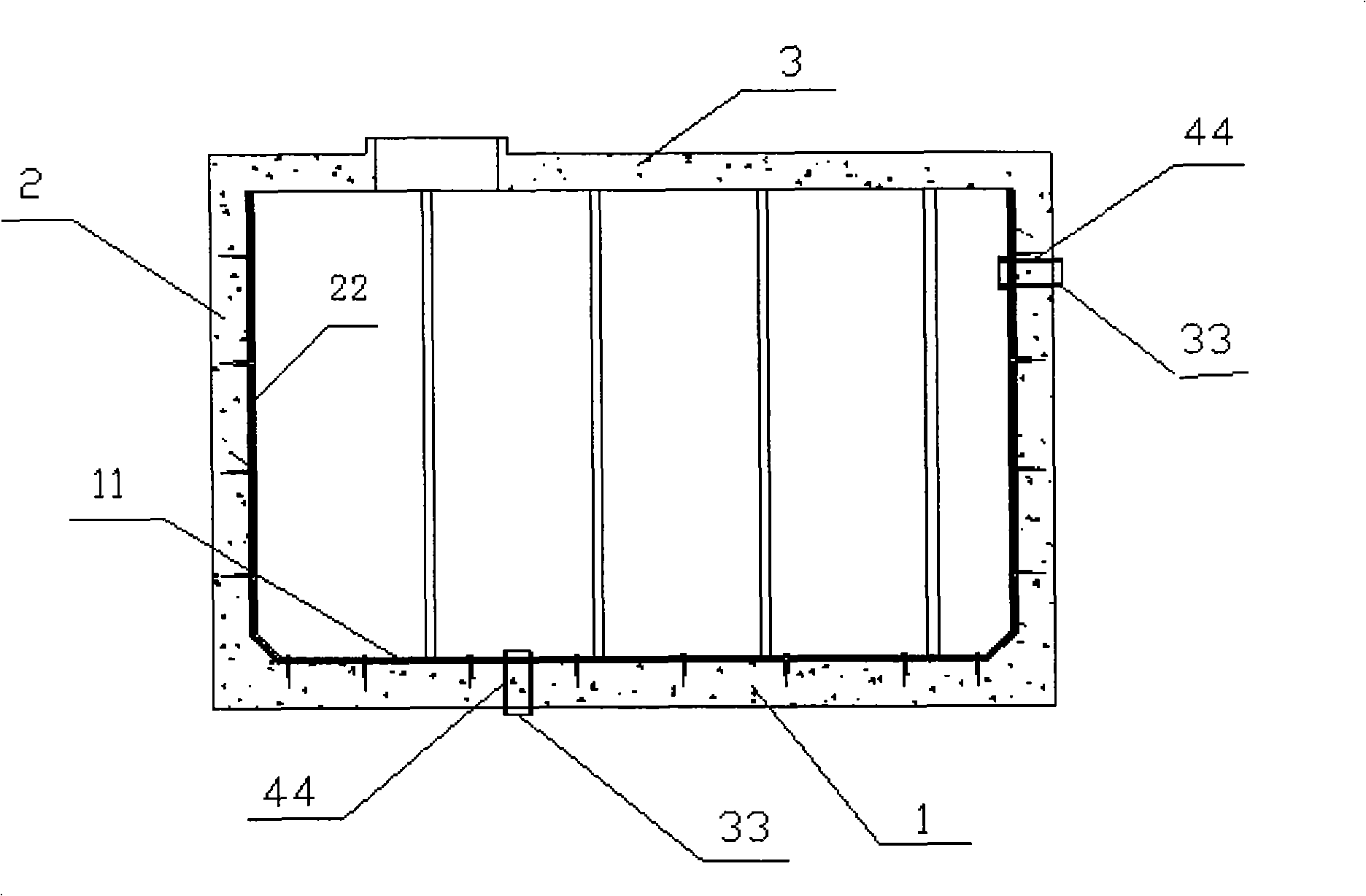

[0011] Such as figure 1 As shown, the above-mentioned pollution-free HDPE plate inner wall concrete water tank includes a reinforced concrete bottom plate 1, a reinforced concrete annular side wall 2 extending upward around the periphery of the bottom plate 1, and a reinforced concrete top plate 3 on the top of the annular side wall 2. The above-mentioned bottom plate 1, annular The side wall 2 and the top plate 3 form an integrated water storage chamber, and the inner wall of the water storage chamber is provided with a water inlet hole 5 and a water outlet hole 6. The difference is that a layer is fixed on the bottom plate 1 and the annular side wall 2, and their sizes correspond to each other. HDPE inner bottom plate 11, HDPE annular inner side plate 22, the inner bottom plate 11 and the inner side plate 22 are welded by heat fusion or snap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com