Super large caliber and non-excavation-use PE pollution discharge tubular product and manufacturing method thereof

A super-large-diameter, non-excavation technology, applied to pipes, rigid pipes, mechanical equipment, etc., to achieve the effects of reducing frictional damping, improving ring stiffness, corrosion resistance and flexibility

Inactive Publication Date: 2009-09-09

ANHUI YOUYI PIPES

View PDF2 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0046] Embodiment 1, get A 62%, B 14%, C 20.9%, D 1.3%, E 1.8%.

Embodiment 2

[0047] Embodiment 2, take A 68%, B 12%, C 16.8%, D 1.7%, E 1.5%.

Embodiment 3

[0048] Embodiment 3, take A 72%, B 10%, C 14.7%, D 2.1%, E 1.2%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

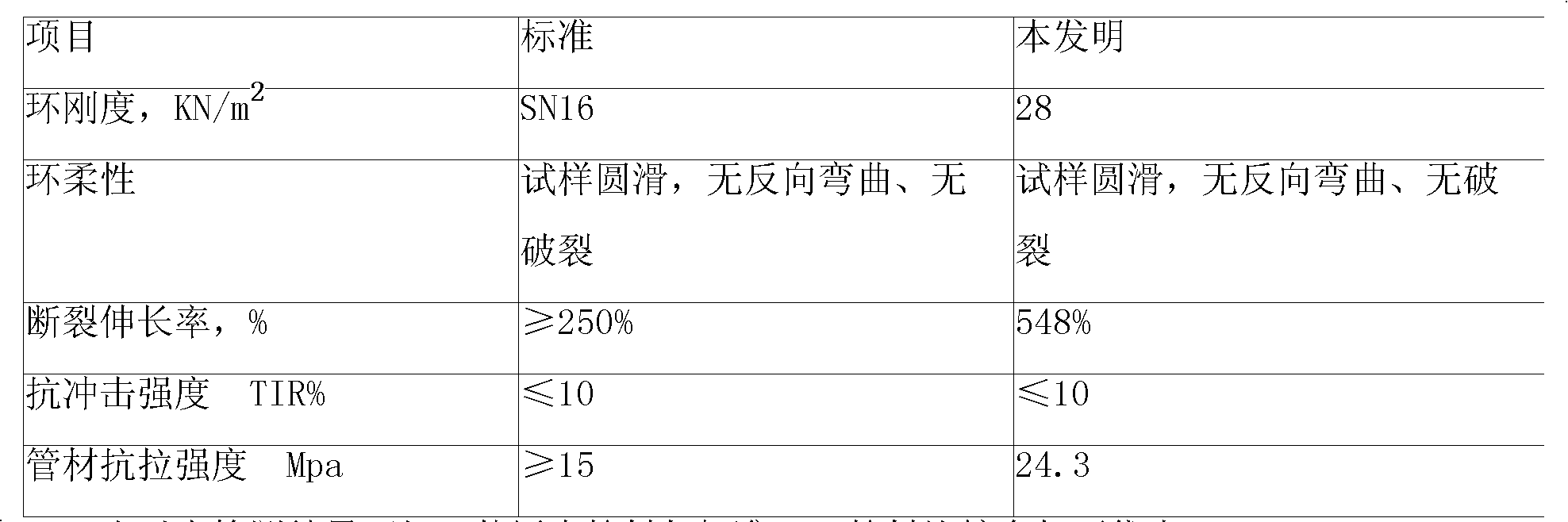

The invention relates to a super large caliber and non-excavation-use PE pollution discharge tubular product and a manufacturing method thereof, wherein, the tubular product are manufactured by the following materials which are arranged according to the following mass percentage after the steps of pelleting and extrusion molding: 60-85% of PE100 pipeline special material; 5-15% of calcium carbonate superfine powder; 7-22% of unit triplet blending modified resin; 1-3% of high molecular weight polyethylene; and 0.2-2% of fluoropolymer. The method comprises the following steps: mixing PE100 pipeline special material accounting for 20-30% of total volume of addition evenly with other components according to proportion and obtaining master batch by extrusion and pelleting; mixing the excess PE100 pipeline special material evenly with the master batch and colorant and drying the mixture for 2-4 hours at the temperature of 0-80 DEG C; and then obtaining fixed-length tubular products after the steps of extrusion, vacuum sizing, cooling and cutting. The tubular products has the characteristic of integration; hot welding is carried out on the pipelines; the pipelines have fine flexibility and scratching-and-cracking-resisting capcacity; in addition, the pipelines has more unique technological and economic advantages when applied to drag construction of non-excavation works.

Description

technical field [0001] The invention relates to a sewage discharge pipe material for non-excavation dragging construction and a preparation method thereof. Background technique [0002] Underground pipelines are an important infrastructure for the survival and development of cities. They are responsible for transmitting important information and energy, and are called the blood vessels of cities. However, with the continuous development of the world economy, the rapid growth of the population, and the continuous acceleration of the urbanization process, the original pipeline design capacity and operation capacity can no longer meet the requirements of modern cities, and the pipeline needs to be continuously built, rebuilt, repaired and expanded. If a large excavation is used for construction, it will cause traffic jams, damage to green gardens, and sometimes because of the existence of rivers, water networks, overpasses, railways, airports and other buildings, it will bring ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16L9/12B29B9/06B29C47/00C08L23/06C08K3/26C08L101/04C08L101/00

Inventor 吴念黄楠伟钱冰瑜殷皖军

Owner ANHUI YOUYI PIPES

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com