An energy-saving type highlight non-trace injection mold temperature control system

A temperature control system and high-gloss traceless technology, which is applied in the field of energy-saving hydrothermal high-gloss traceless injection mold temperature control system, can solve the problems of waste of high-temperature heat energy, wasted electric energy, not economical and energy-saving, etc., and achieve energy-saving effect, energy-saving, The effect of avoiding wasted power consumption and expanding the scope of mold adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

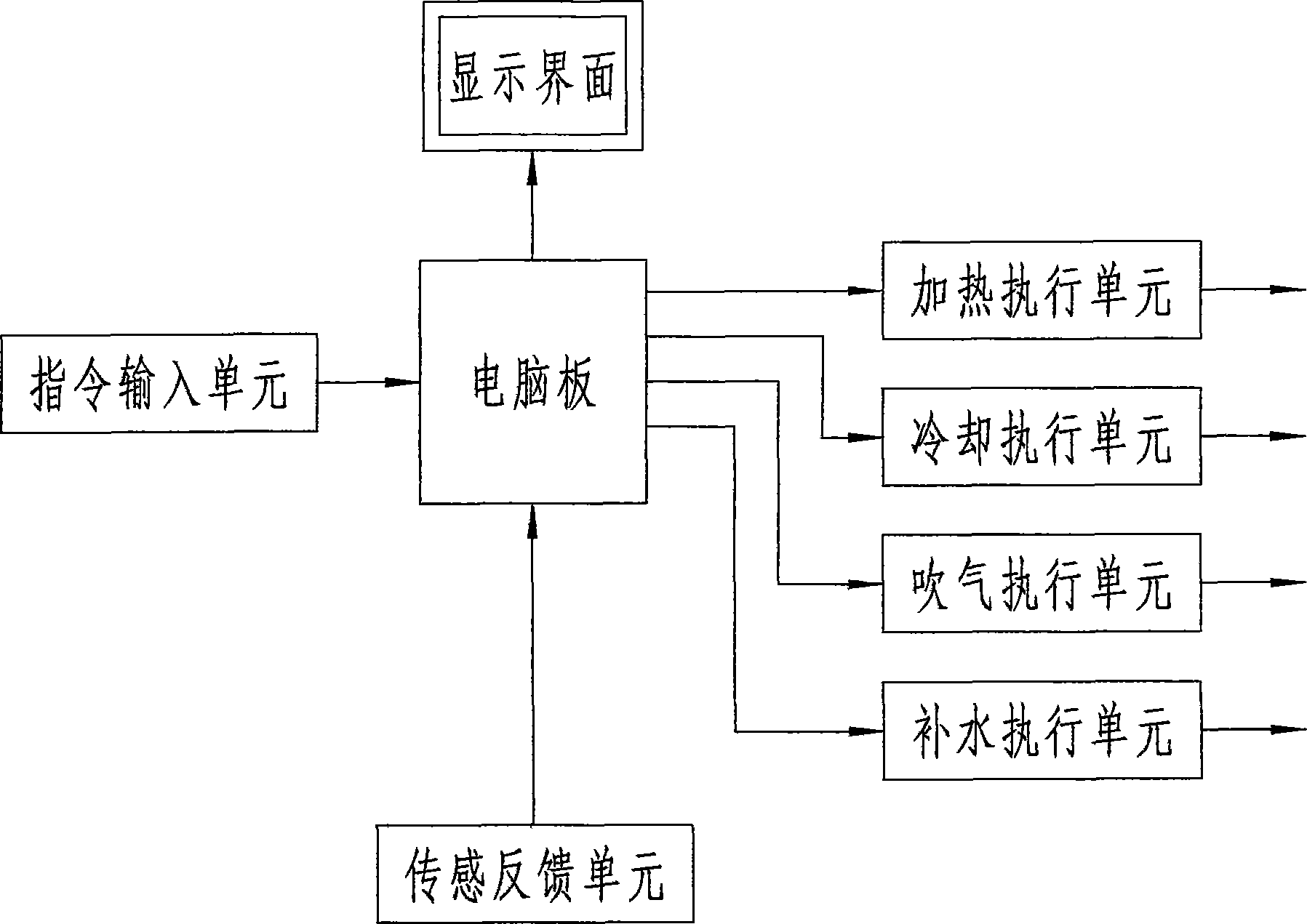

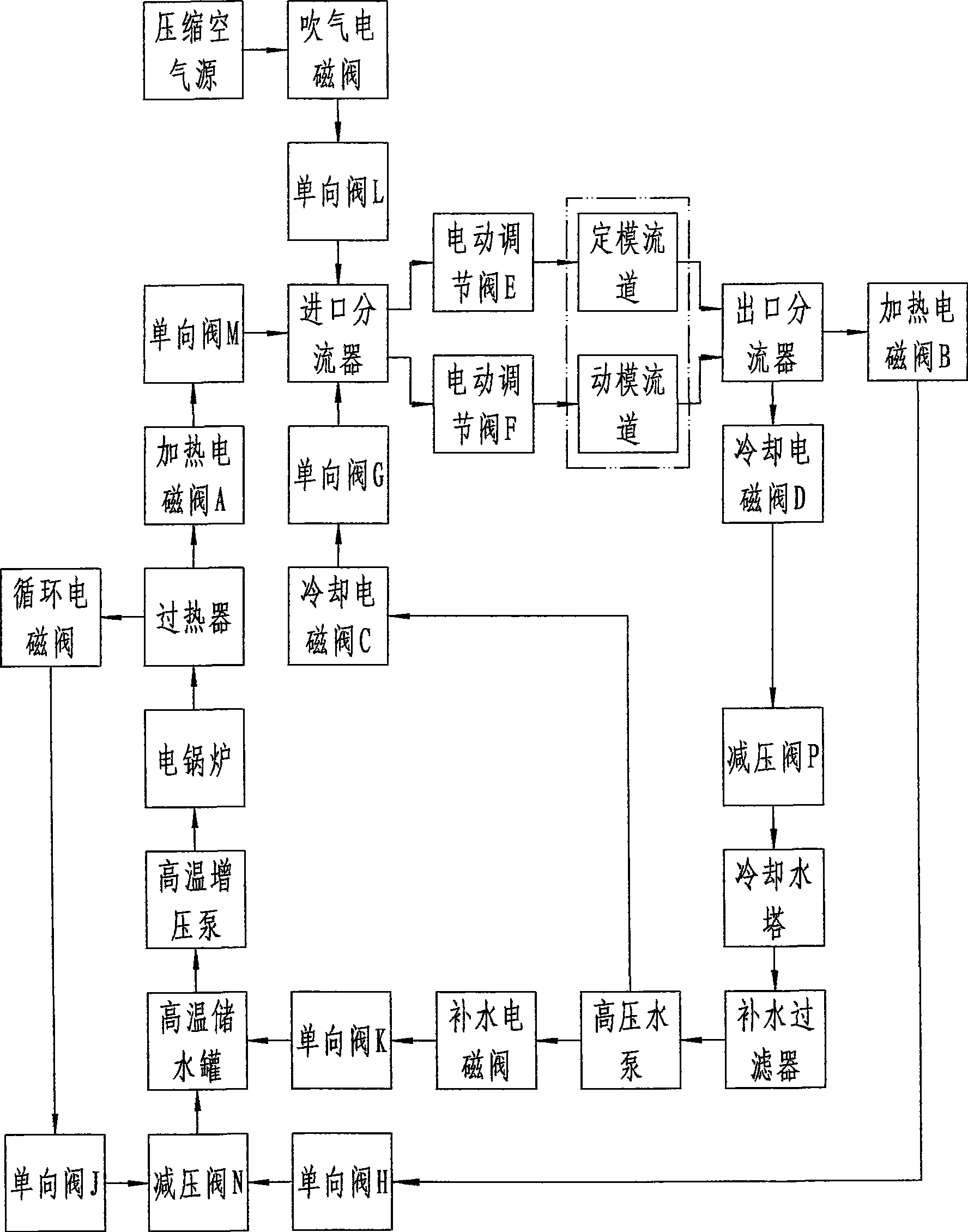

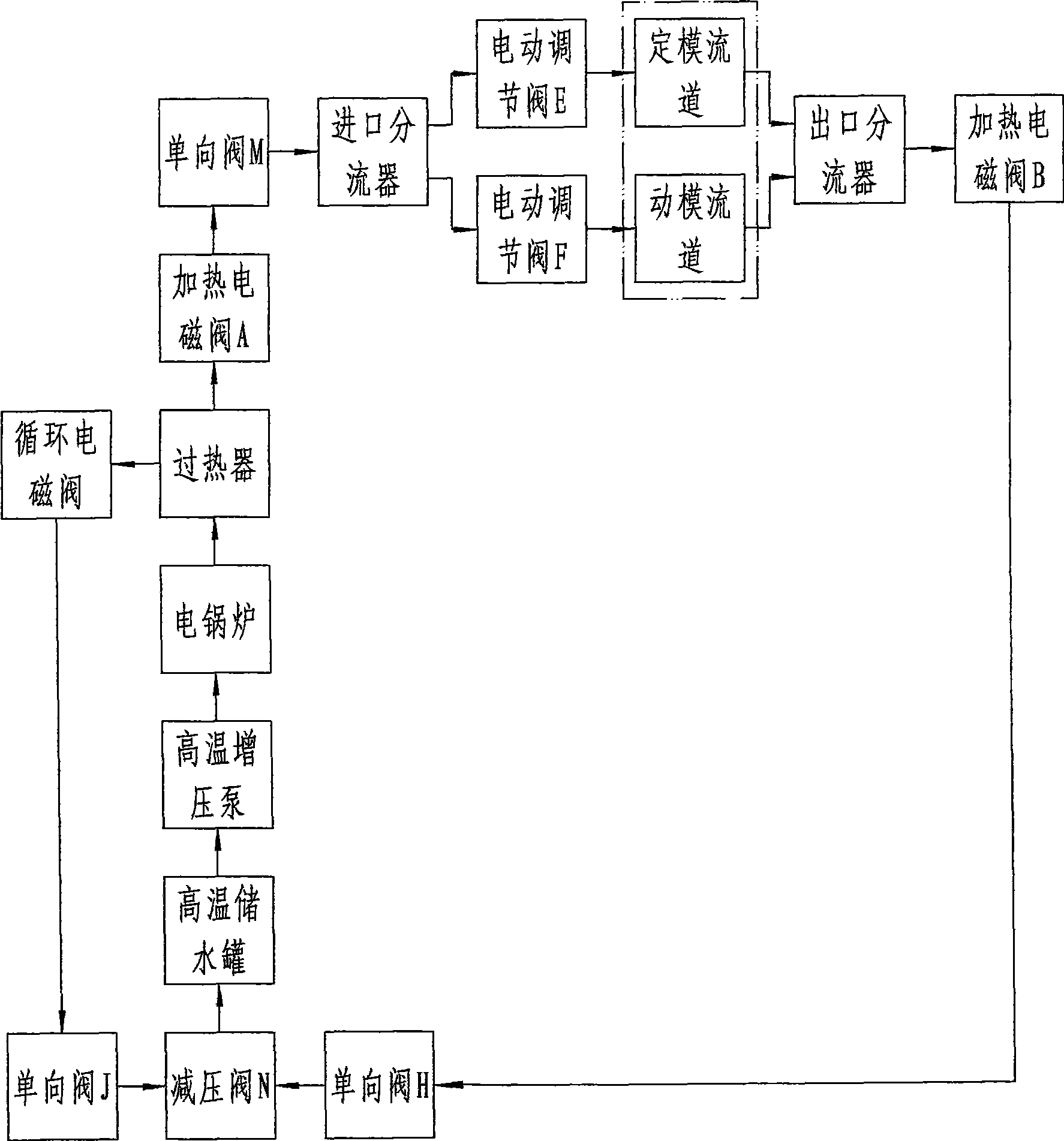

[0033] refer to Figure 1 to Figure 7 , an energy-saving hydrothermal high-gloss non-trace injection mold temperature control system of the present invention includes a mold temperature controller part, a split-and-close circuit control link, a heating part, a water-cooling part, an air blowing part, and a water replenishing part, wherein: the mold The warmer part includes the computer board and its instruction input unit, sensor feedback unit, display interface, heating execution unit, cooling execution unit, blowing execution unit, water replenishment execution unit, and regulated power supply. Through given instructions, parameter feedback, Program operation and output execution realize closed-loop automatic control, which is the central control part of the system, in which the computer board is a programmable microcomputer controller, the command input unit includes the operation keyboard and USB interface, and the sensor feedback unit includes the temperature, The pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com