Method for producing copper and aluminium composite slide wire

A technology of copper-aluminum compounding and production methods, which is applied in the field of material processing, can solve problems such as weak copper-aluminum binding force, large amount of denaturation, and influence on electrical conductivity, etc., and achieve good electrical performance, excellent bonding rate, and good bonding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

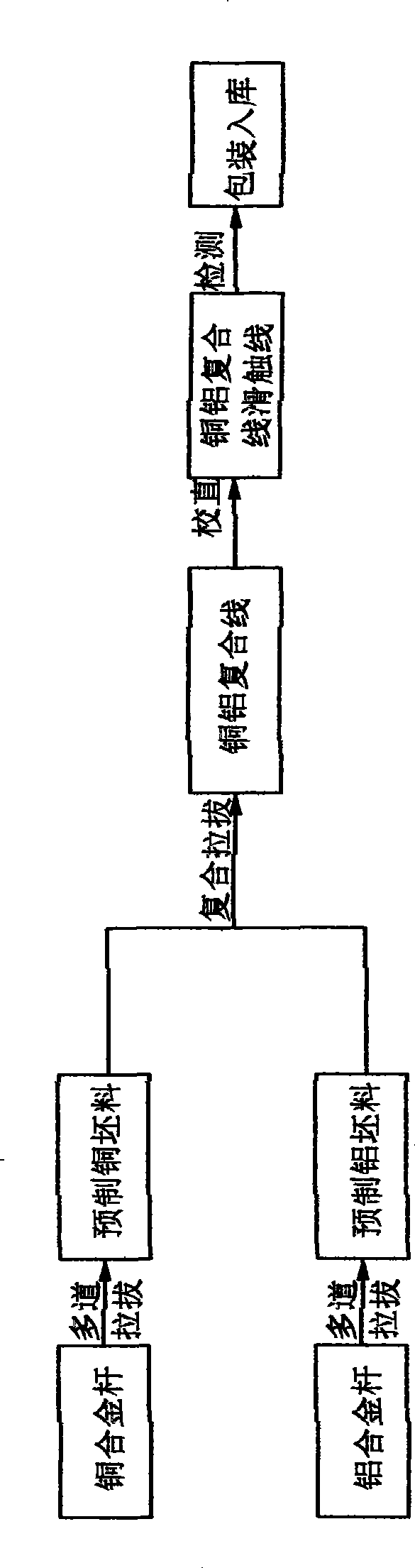

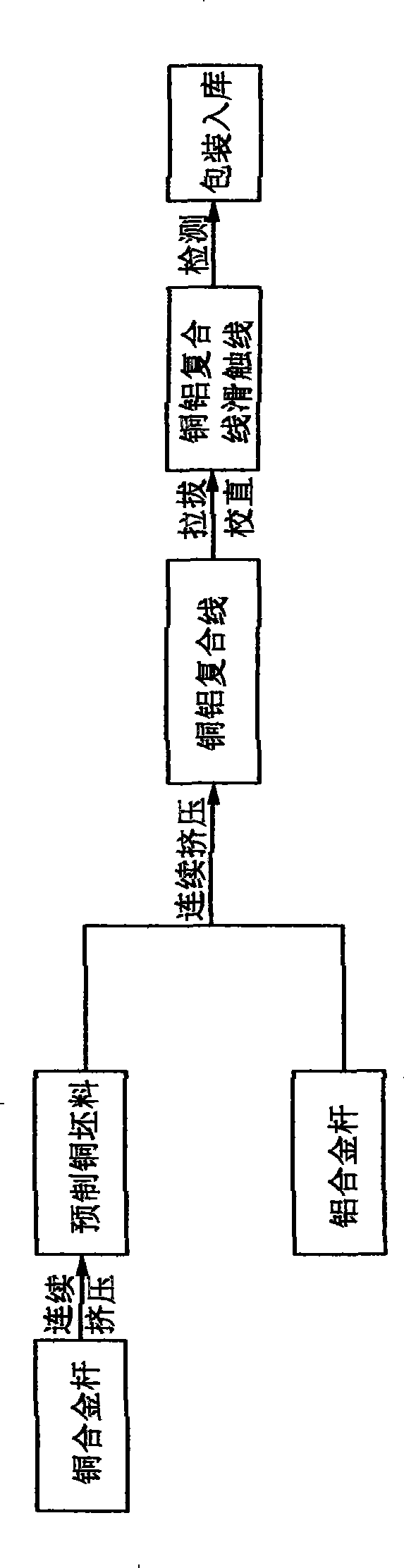

[0033] like figure 2 Shown, the production method of copper-aluminum composite trolley line of the present invention, comprises the following steps:

[0034] 1. Continuous extrusion of prefabricated copper billets

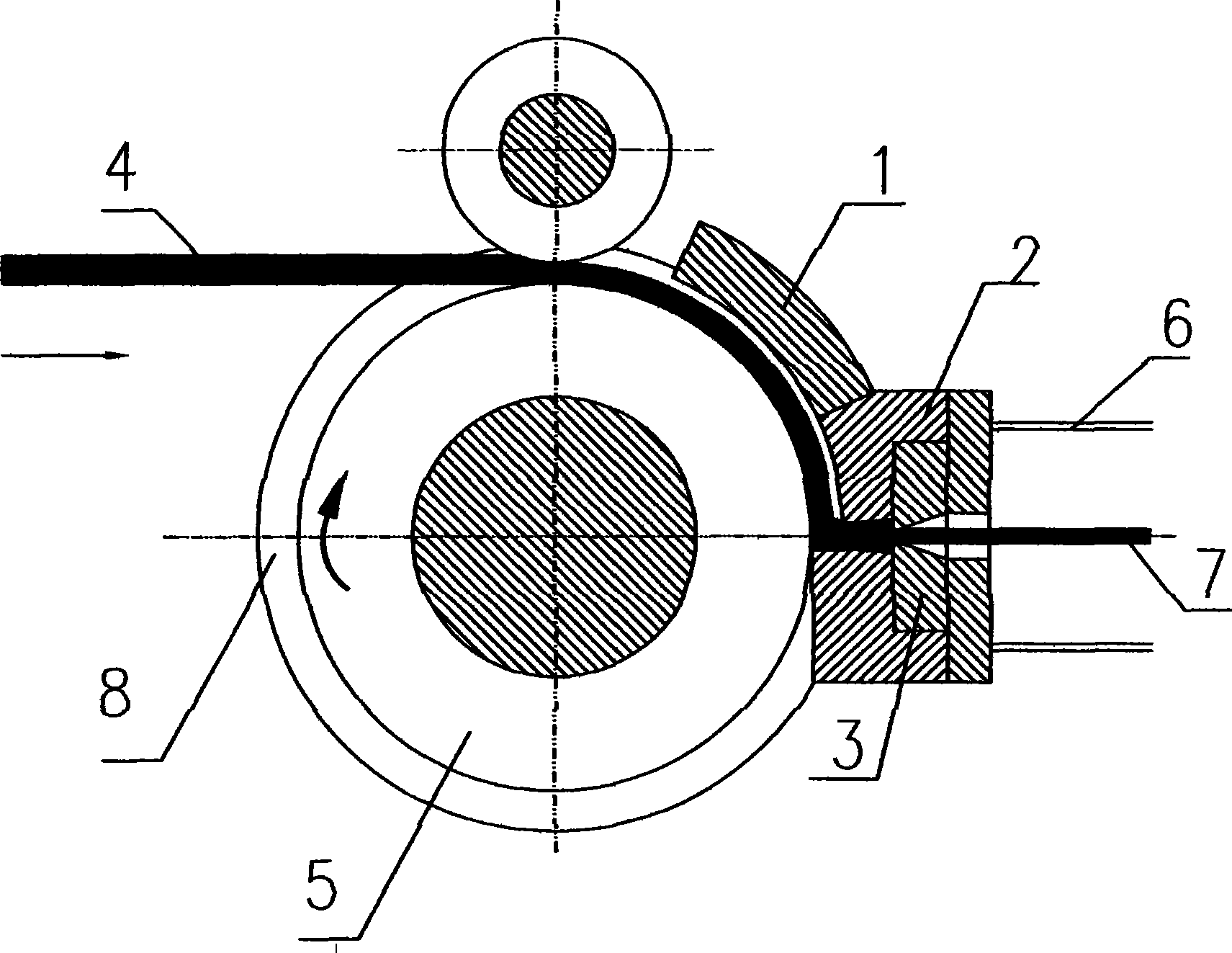

[0035] Using φ12mm—φ30mm copper alloy rods as raw materials, using TJL300 continuous extruder, the copper alloy rods are continuously forced into the die cavity of the extruder through the feeding port of the extruder, and heat is generated by the gravity rotation friction of the extrusion wheel, so that the copper The alloy rod is extruded into the extrusion die in a specially designed vacuum cavity to realize thermal deformation, combined with image 3 As shown, the die cavity of the extruder of the present invention is mainly composed of three parts: the rubber introduction head 1, the cavity 2 and the extrusion die 3. The rubber introduction head 1 is under high pressure at 800 ° C, and the colloidal copper 4 is introduced from the groove 8 of the extrusion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com