Method for preparing pinaverium bromide and application thereof

A kind of pinaverium bromide, reaction technology, applied in the field of preparation technology of pinaverium bromide, can solve the problem of low content of pinaverium bromide cis isomer etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

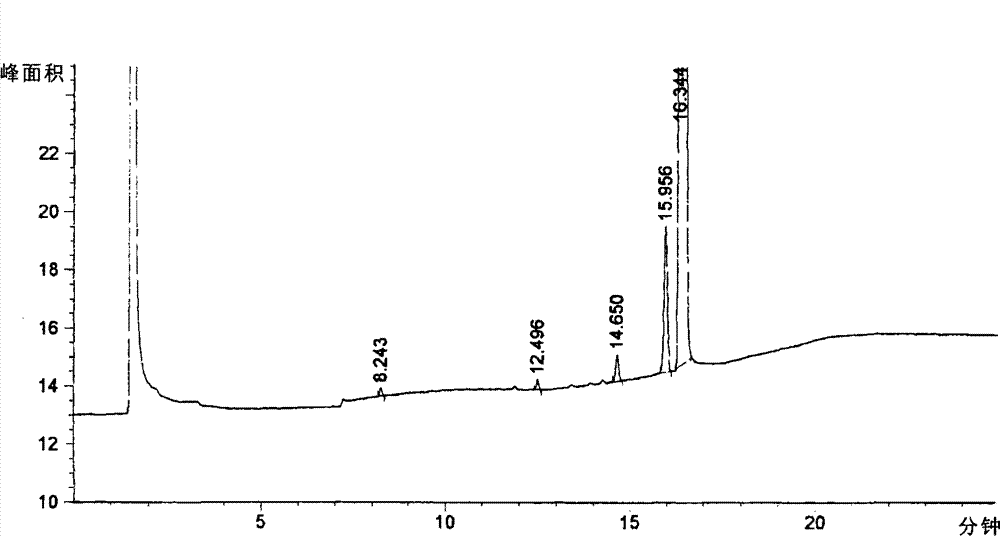

Image

Examples

preparation example Construction

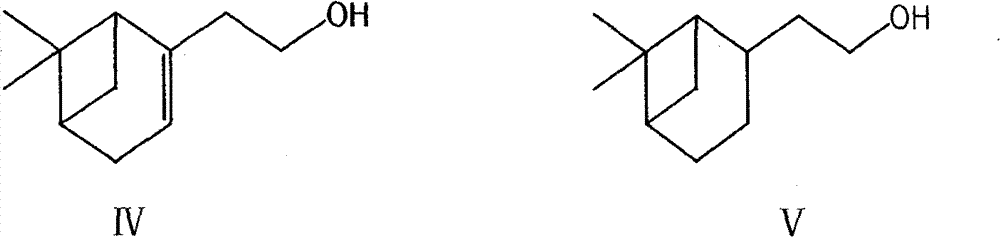

[0056] The preparation method of the intermediate compound shown in formula II provided by the present invention comprises steps:

[0057] (a) Nopol alcohol, palladium carbon and methanol with chemical structure such as formula IV are mixed and reacted to obtain a compound with chemical structure such as formula V;

[0058]

[0059] (b) mixing the compound of formula V obtained in step (a), toluene and sodium hydroxide, and heating for reaction;

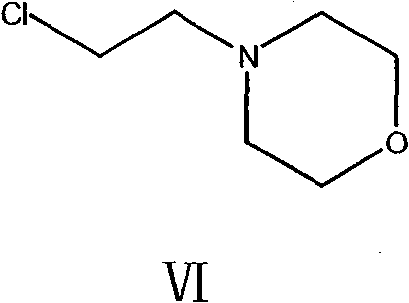

[0060] (c) Add the mixed solution of the compound of chemical structure such as formula VI and toluene, reflux, cool to room temperature;

[0061] (d) adding water for extraction, taking the organic layer, and distilling under reduced pressure to obtain the compound intermediate of formula II.

[0062] A preferred solution is:

[0063] (a) Nopol alcohol, palladium carbon and methanol with chemical structure such as formula IV were mixed and reacted for 2-8 hours, filtered, and methanol was removed to obtain a compound with chemica...

Embodiment 1

[0098] Preparation of 2-[2-(2-morpholinyl-2-ethoxyl-ethyl)]-6,6-dimethylnoprene (formula II)

[0099] 1. At room temperature, put into the autoclave 600L of methanol, 100Kg of Nopol alcohol (formula IV), 10Kg of palladium carbon, react under 6-7 kg of hydrogen pressure for 4-6 hours, filter the catalyst, wash with methanol, and evaporate under reduced pressure Methanol to obtain 90Kg of the compound of formula V, with a yield of 88.7%;

[0100] 2. Then add 300L of toluene and 50Kg of the compound of formula V into the 1000L reactor, put in 13kg of sodium hydroxide at room temperature, raise the temperature to reflux, and react for 2 hours;

[0101] 3. Then add the mixed solution of 45kg 2-chloroethylmorpholine (formula VI) and 100L toluene, reflux reaction for 1 hour after adding, cool, add 300L water for extraction, and separate the organic layer;

[0102] 4. The aqueous layer was extracted twice with toluene, 200 L each time, the organic layers were combined, washed with 20...

Embodiment 2

[0106] Preparation of 2-[2-(2-morpholinyl-2-ethoxyl-ethyl)]-6,6-dimethylnoprene (formula II)

[0107] 1. Under room temperature, drop into methanol 600L in the autoclave, Nopol alcohol 100Kg (formula IV), palladium carbon 10Kg, react 2 hours under 9-10 kilograms of hydrogen pressure, filter catalyst, wash with methanol, decompress and evaporate methyl alcohol, 91.3Kg of the compound of formula V was obtained, with a yield of 90.4%;

[0108] 2. Then add 300L of toluene and 50Kg of the compound of formula V into the 1000L reactor, put in 13kg of sodium hydroxide at room temperature, raise the temperature to reflux, and react for 2 hours;

[0109] 3. Then add the mixed solution of 45kg 2-chloroethylmorpholine (formula VI) and 100L toluene, reflux reaction for 1 hour after adding, cool, add 300L water for extraction, and separate the organic layer;

[0110] 4. The aqueous layer was extracted twice with toluene, 200 L each time, the organic layers were combined, washed with 200 L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com