Coating device for coating wire with ice-snow prevention layers

An anti-ice, snow and wire technology, applied in conductors, insulated conductors, cable/conductor manufacturing, etc., can solve problems such as grounding short circuit of transmission wires, distortion of transmission towers, line tripping, etc., achieving low noise hazard, good isolation measures, and not easy to wipe hair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

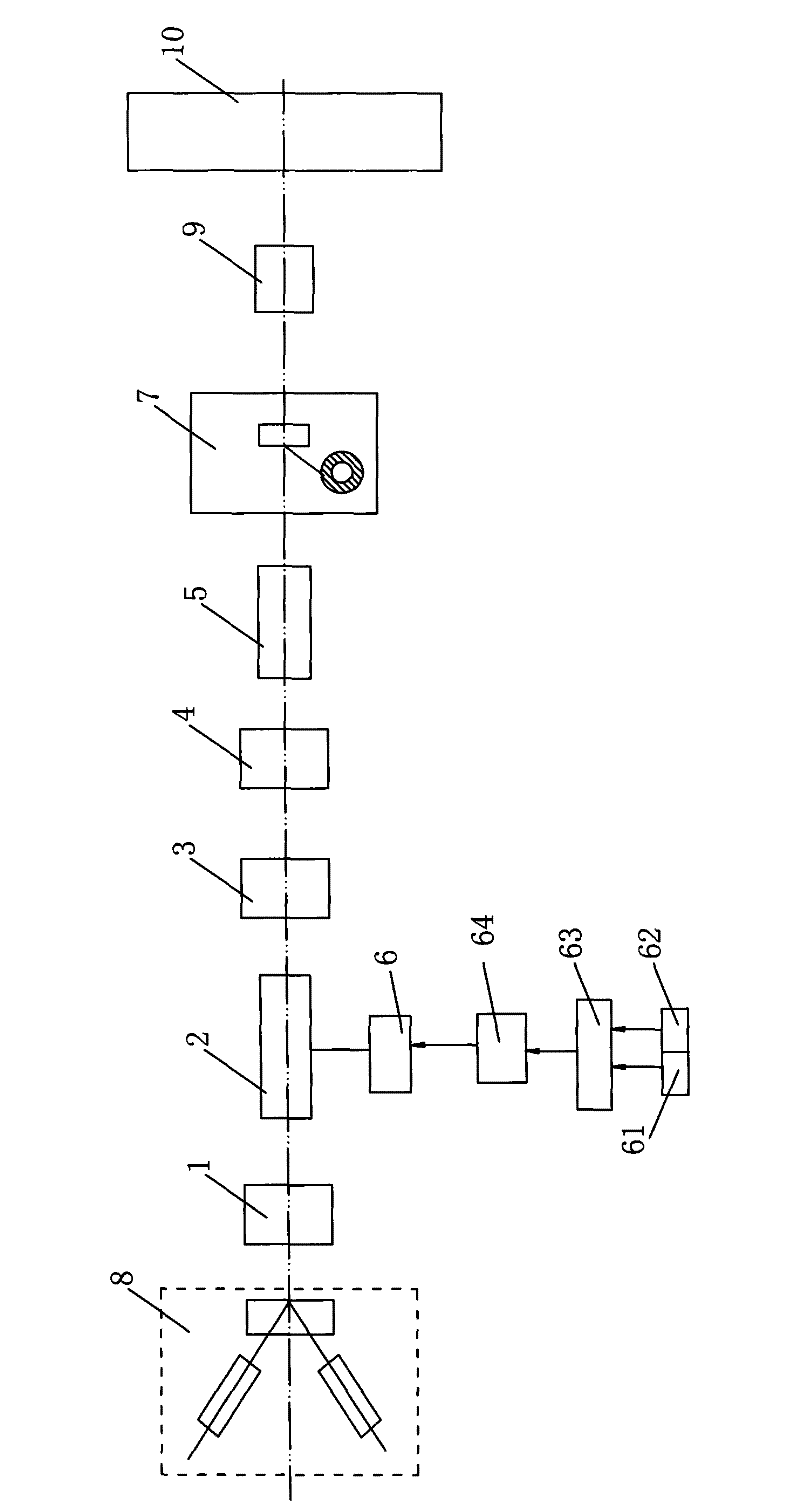

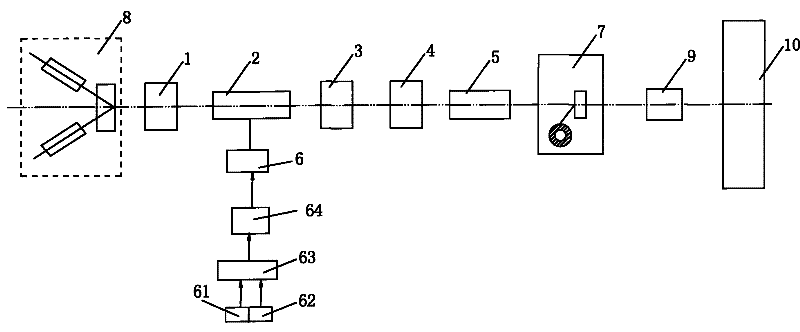

[0023] As shown in the figure, it is a structural schematic diagram of the coating equipment used in the coating method of the anti-ice and snow layer of the wire, including the front positioning mold 1, the spraying box 2, the sizing mold 3, and the rear positioning mold 4, which are arranged in sequence with the same center height And drying box 5, spraying box 2 is connected on the total storage box 6 by booster pump through pressure-resistant pipeline; It also includes storage tank No. 1 and No. No. storage box 62, a mixing box 64 with a stirrer for storing the C mixture, and a metering pound 63 connecting the No. 1 storage box 61, the No. 1 storage box 62 and the mixing box 64, the No. 1 storage box 61, the No. 2 storage box 62 communicates with mixing tank 64 through weighing scale 63, and mixing tank 64 communicates with total storage tank 6.

[0024] The polyurea elastomer waterproof coating can be purchased from Hebei Jinkun Engineering Materials Co., Ltd. The purchas...

Embodiment 2

[0029] Embodiment 2: The anti-ice and snow paint coating equipment is placed between the stranding mold 8 and the traction wheel 9 of the stranding cage in the last section of the stranding machine.

[0030] (1) Spray a liquid waterproof paint on the surface of the wire to form a coating layer.

[0031] Assuming that a 0.1mm thick coating layer needs to be obtained, after the wires with a diameter of 20mm are stranded and formed, under the action of the front positioning mold 1 and the rear positioning mold 4 with a front and rear aperture of 20.4mm, the front positioning mold 1 and the rear positioning mold 4 are ensured at the same time. The height of the hole center of the positioning die 4 is consistent with the center height of the stranding unit, so that when the wire is continuously twisted and manufactured, it is kept running at the center height of the entire unit; the wire passes through the front positioning die 1 and enters the spraying box 2 for pressure spraying, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com