Online measurement and control method and device of filling ratio of flux-cored wire forming machine

A technology of flux-cored welding wire and measurement control, which is applied to the detection of flux-cored welding wire forming equipment and the field of online measurement and control of the filling rate of the flux-cored welding wire forming machine, can solve the problem that the filling rate of the flux-cored welding wire cannot be measured, and the filling rate cannot be automatically measured online. and other problems, to achieve the effect of flexible control and adjustment, easy to master, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

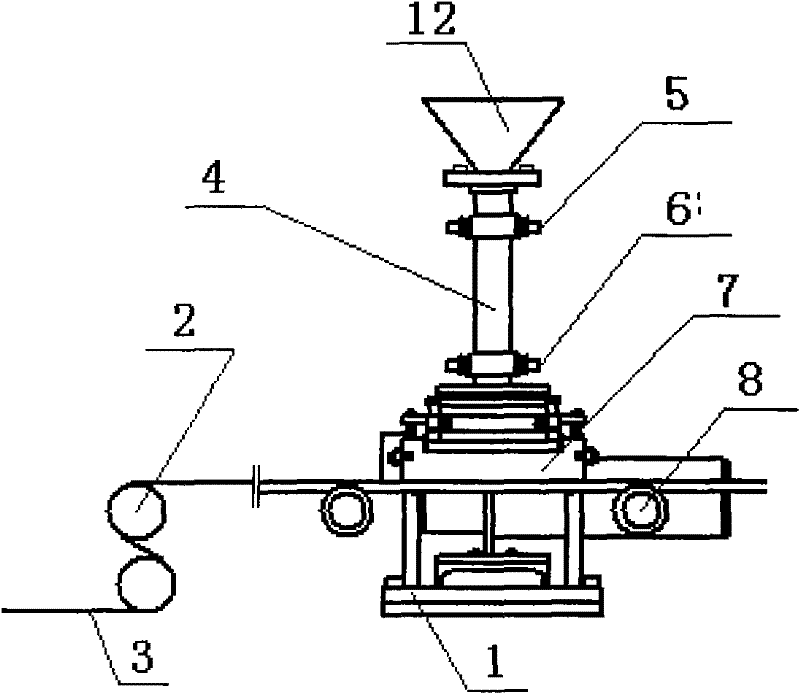

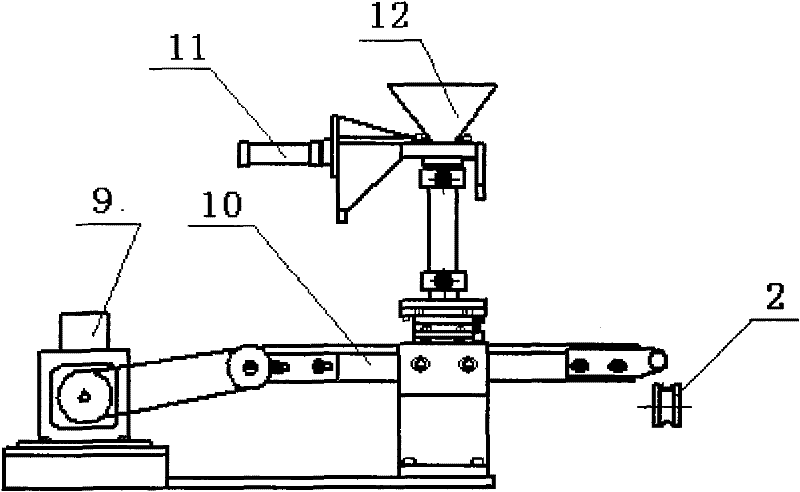

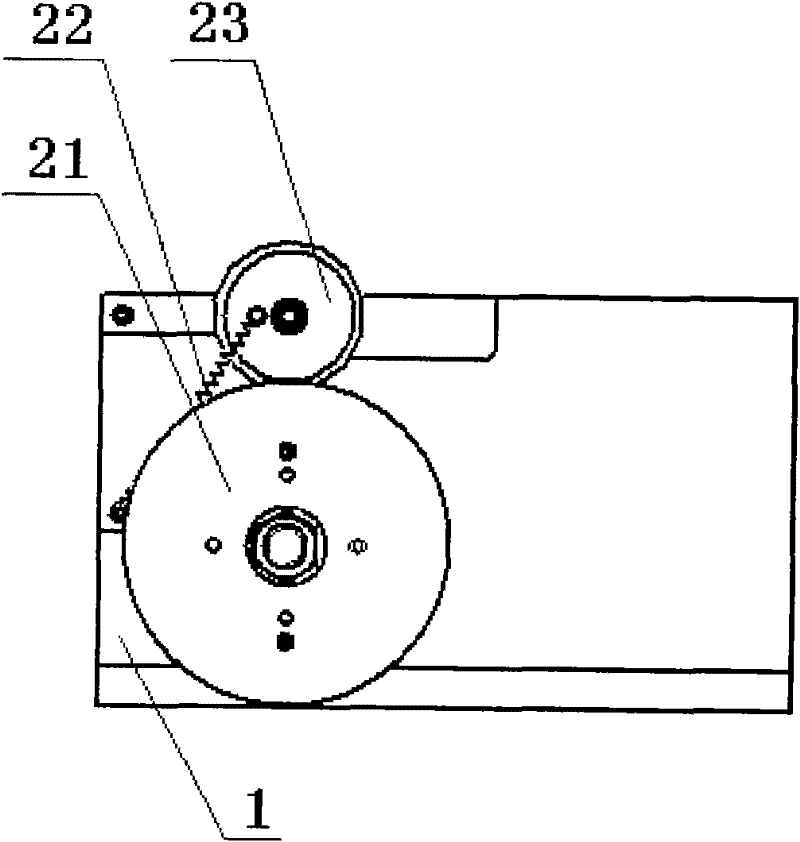

[0027] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

[0028] The filling rate online measurement and control method of the flux-cored welding wire forming machine of the present invention comprises the following steps:

[0029] A. Add drug core powder to the powder hopper 12 of the molding machine and the belt powder feeding assembly 10, adjust and fix the powder feeding gap on the belt powder feeding assembly 10, and load the steel belt 3 into the steel strip rolling forming equipment , turn on the belt powder feeding assembly 10 and the steel strip rolling forming equipment, measure the powder flow rate on the belt powder feeding assembly 10 and the speed of the steel strip 3 on the steel strip rolling forming equipment, and calculate the passing time in the same time period T The powder weight W1 of the belt powder feeding assembly 10, and the weight W2 of the steel belt 3 passi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com