Polymeric composite in-situ growth nano-particle molecular film and preparation method thereof

A nanoparticle, in-situ growth technology, applied in lubricating compositions, chemical instruments and methods, layered products, etc., can solve the problems of affecting the performance of molecular films, prone to agglomeration, etc., and achieve good wear resistance and uniform distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

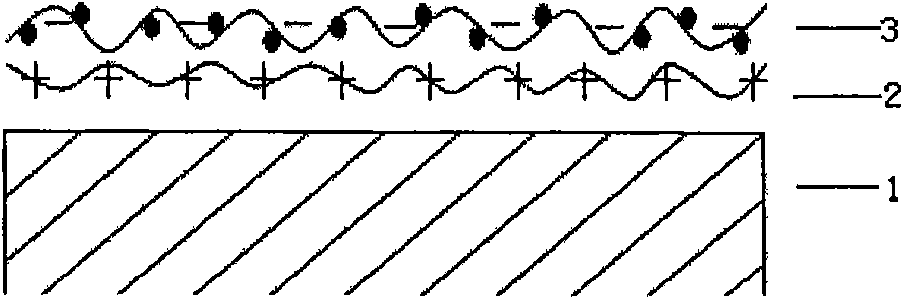

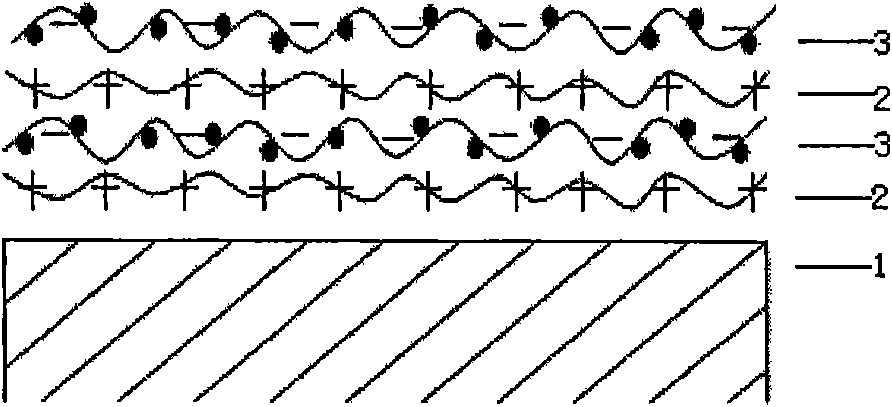

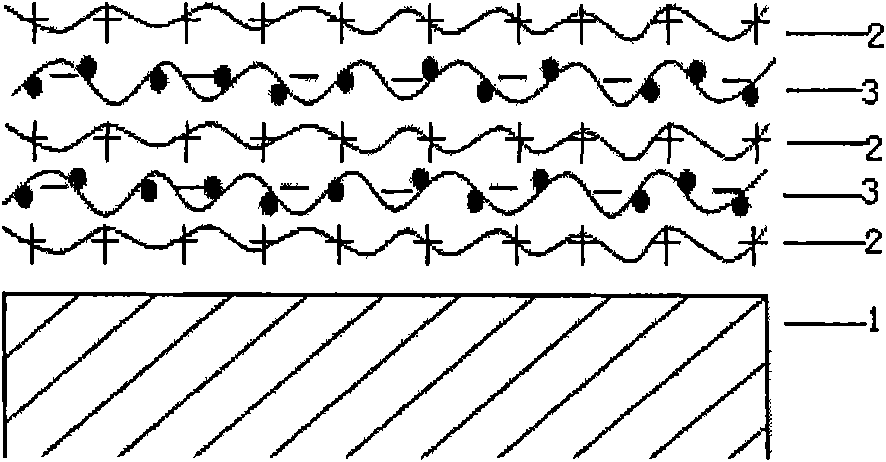

Image

Examples

Embodiment 1

[0038] Embodiment 1, the preparation method of polymer composite in-situ growth nanoparticle molecular film

[0039] The preparation method of the polymer composite in-situ growth nanoparticle molecular film in this embodiment is specifically carried out according to the following operations:

[0040] (1) Preparation of the substrate:

[0041] Step a1: Take a glass substrate (or quartz substrate or silicon substrate) and clean it; the cleaning step can be carried out according to conventional operations in this field, for example, first use petroleum ether to scrub and clean to remove the wax layer, and then use toluene, acetone Ultrasonic cleaning with polar solvents such as chloroform and / or chloroform to remove other organic layers, and then ultrasonic cleaning with ethanol and water to remove particles and other pollutants on the surface of the substrate;

[0042] Step a: immerse the above-mentioned cleaned substrate in 80°C containing H 2 SO 4 with H 2 o 2 solution f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com