Method and device for measuring shape and size of workpiece with high-temperature end and low-temperature end on line

A measuring device and low-temperature end technology, which is used in the on-line measurement of the shape and size of the deformation zone in dieless drawing, and the on-line measurement of the shape and size of workpieces coexisting at the high-temperature end and the low-temperature end. Problems such as online measurement of workpiece shape and size coexist in low temperature area, no high temperature end and low temperature end, to achieve the effect of fast measurement speed, improved efficiency and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] An example of the specific implementation of the present invention will be described below in conjunction with the accompanying drawings.

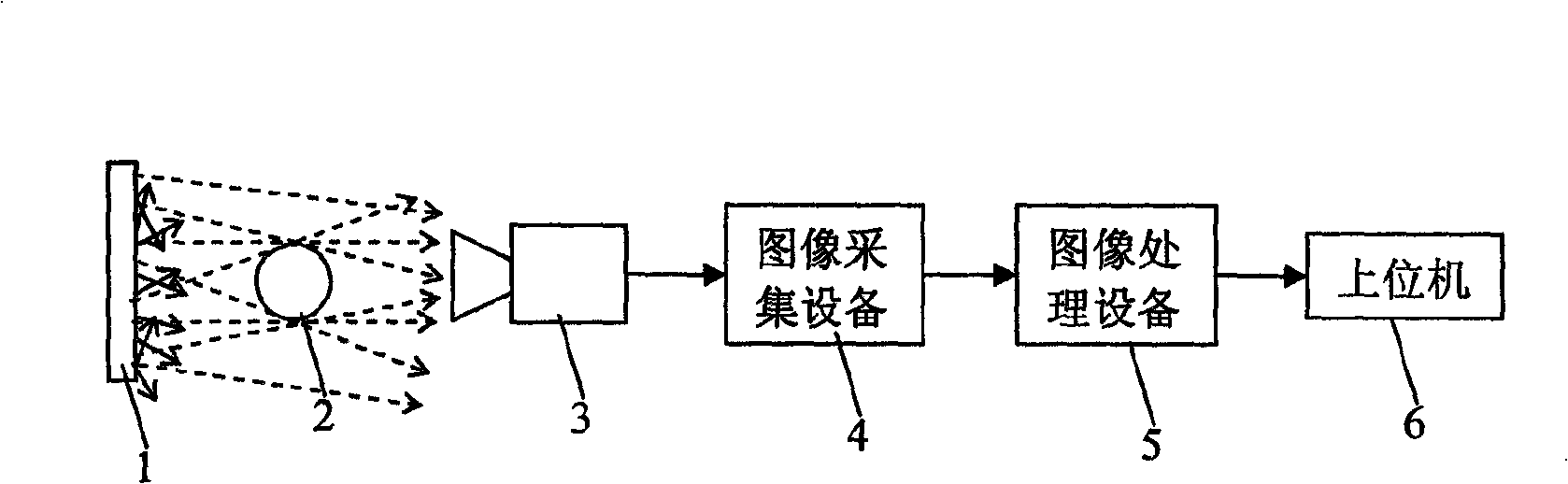

[0026] Diffuse backlight 1 adopts a backlight composed of compactly arranged high-brightness LED substrates and frosted glass, area array CCD camera 3 is Panasonic CAMERAANPVC1210, image acquisition device 4 is Panasonic PV500 image acquisition equipment, and image processing equipment 5 is Panasonic PV500 image processing Device, the upper computer 6 is NI PXI-1030 produced by National Instruments, and LabVIEW 8.5 software is installed in the upper computer to realize data acquisition and processing.

[0027] The workpiece 2 to be tested is installed in the dieless drawing equipment, and undergoes dieless drawing deformation. The diffuse backlight 1 and the area array CCD camera 3 are respectively placed on both sides of the workpiece 2, and the optical axis of the area array CCD camera 3 is perpendicular to the axial direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com