Annular water flow type machine for cleaning fruits and vegetables

A fruit and vegetable washing machine, annular water flow technology, applied in the application, food processing, food science and other directions, can solve the problems of easy leakage, high sealing gasket production cost, low processing accuracy of sealing gasket production cost, etc., and achieves low processing accuracy requirements, The effect of reliable sealing and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

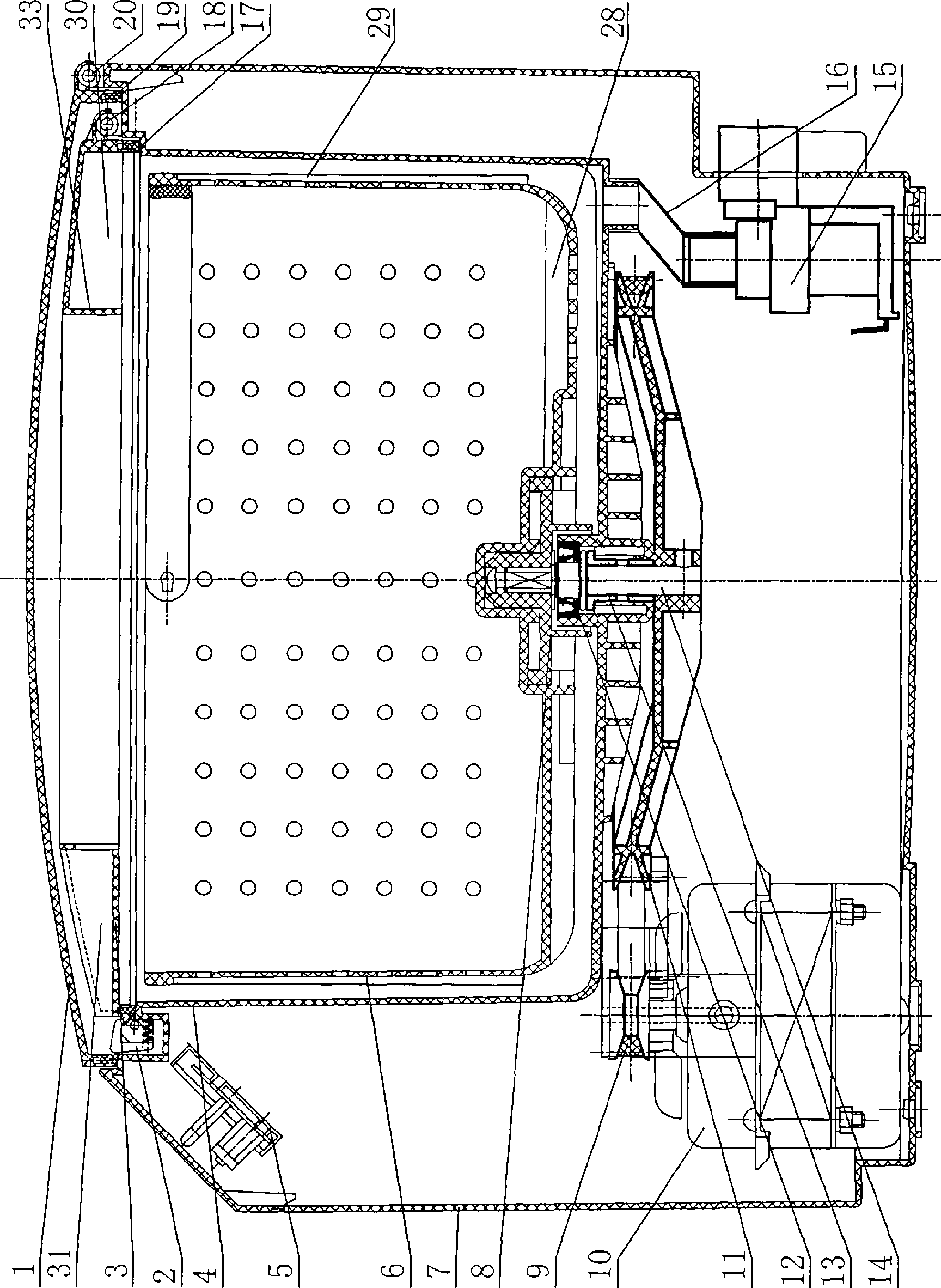

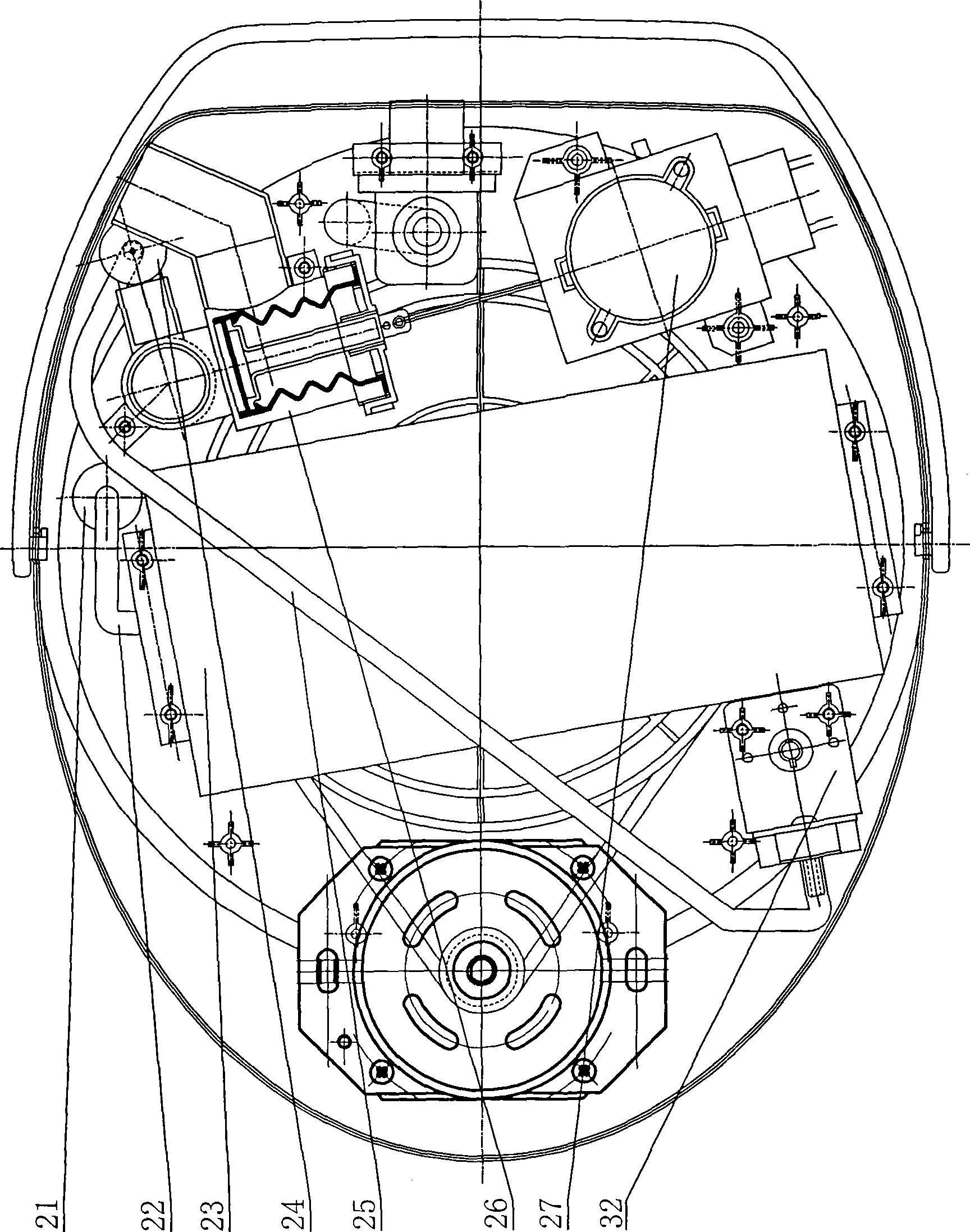

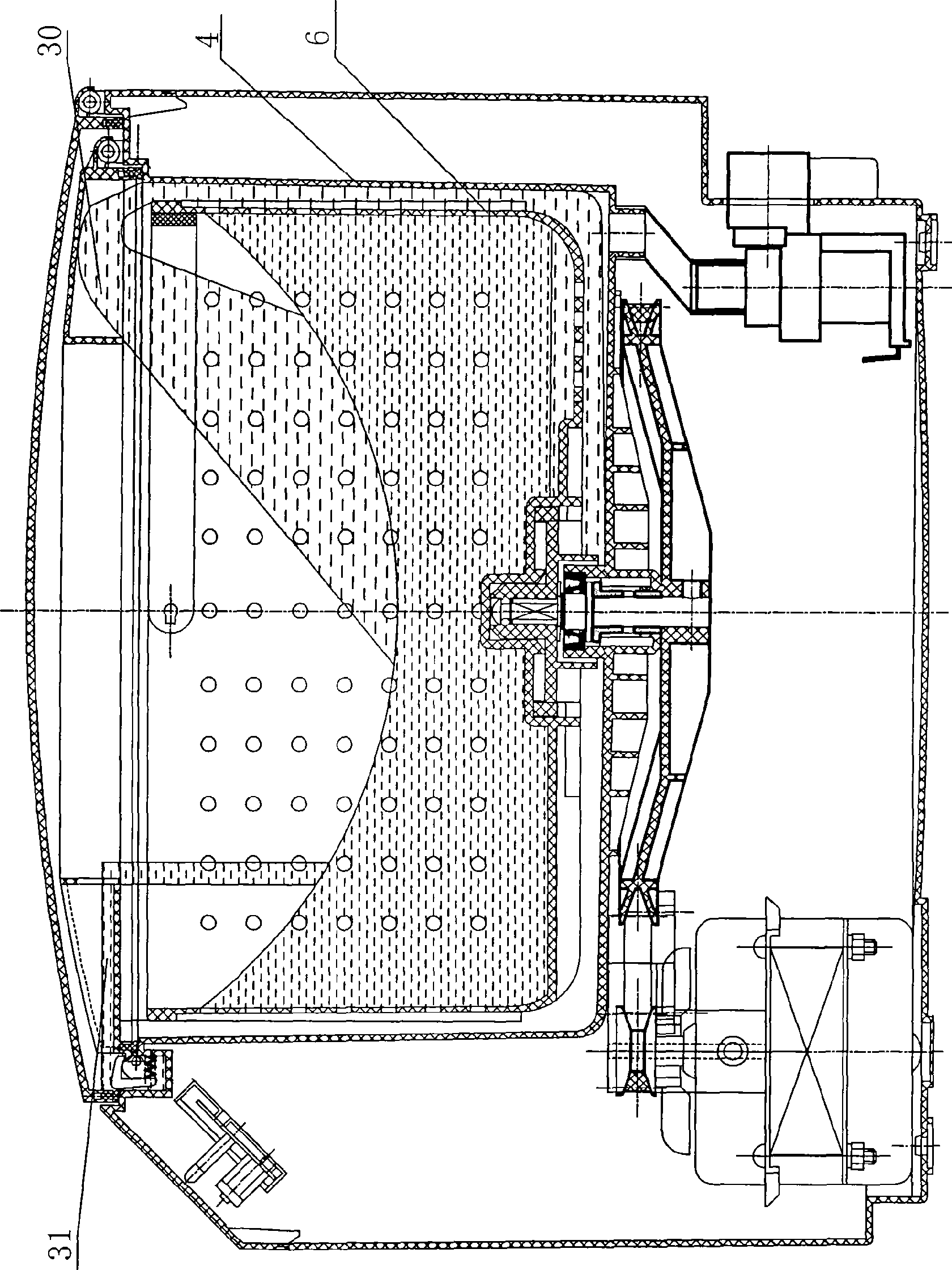

[0021] Description with reference to the accompanying drawings.

[0022] The casing 7 supports the washing tub 4 and places the driving motor 10, the water inlet valve 15, the ozone generator 23, the air chamber 24, the water level switch 32, the drain valve part 26, and the tractor 27. The washing basket 6 of circular through hole is arranged on the wall and the axis of washing bucket 4 coincides, and also can be the through hole of other forms such as elongate on the washing basket 6 walls. The power of the motor 10 is transmitted to the transmission shaft 14 through the pulley on the output shaft, the transmission belt 9, and the pulley 11. The transmission shaft 14 cooperates with the inner hole of the bearing 13 in the center hole of the washing tub 4, and the upper end of the transmission shaft 14 is driven by the transmission turntable 8. The washing basket 6 has a water seal 12 between the transmission shaft 14 and the washing tub 4 . Controller 5 is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com