Fuzzy control heating method for soymilk machine and similar food processor

A food cooking machine and fuzzy control technology, applied in food preparation, food science, beverage preparation equipment, etc., can solve the problems of affecting the production effect of soybean milk machine, overflowing soybean milk, undercooking, etc., and achieve the effect of improving the production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with accompanying drawing (embodiment):

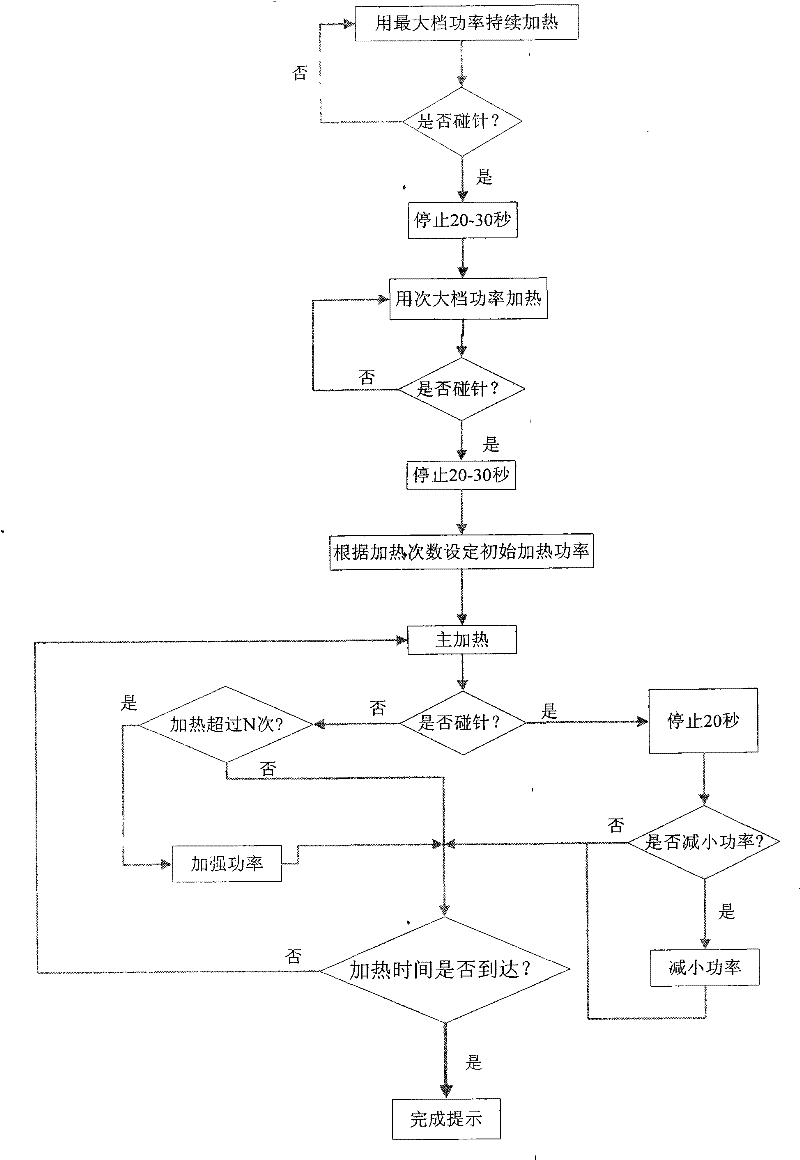

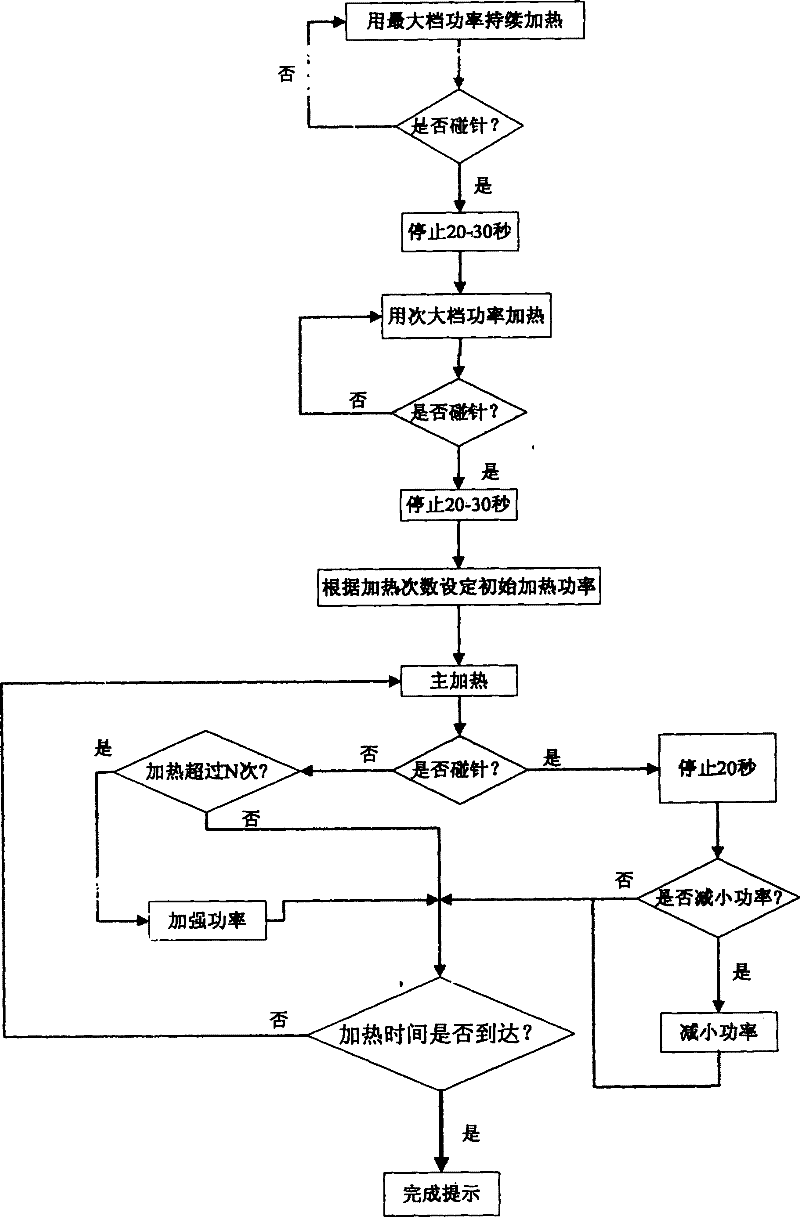

[0009] refer to figure 1 , The single-chip microcomputer (MCU) in the soymilk machine and food cooking machine sets the post-cooking power to 6 levels according to the power of the heating tube of the soymilk machine and the position of the heating tube (such as bottom heating, top heating). And set the pause time after touching the needle according to these parameters, and use one of the gears as the standard power gear. The entire cooking process is divided into three stages. The first stage is to use the maximum power to intermittently heat until the needle is touched and then stop for a certain period of time. The second stage is to use the standard power file to heat until the needle is touched, record the number of cycle heating when the needle is touched, and set the starting heating power of the third stage according to the number of cycle he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com