Waste gas treatment method, system and dissolvant type spraying/drawing machine

A waste gas treatment and waste gas treatment device technology, applied in separation methods, chemical instruments and methods, printing, etc., can solve problems such as human hazards, large space occupied by inkjet printers, and environmental pollution, so as to reduce the occupied space and protect the environment. Good health and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

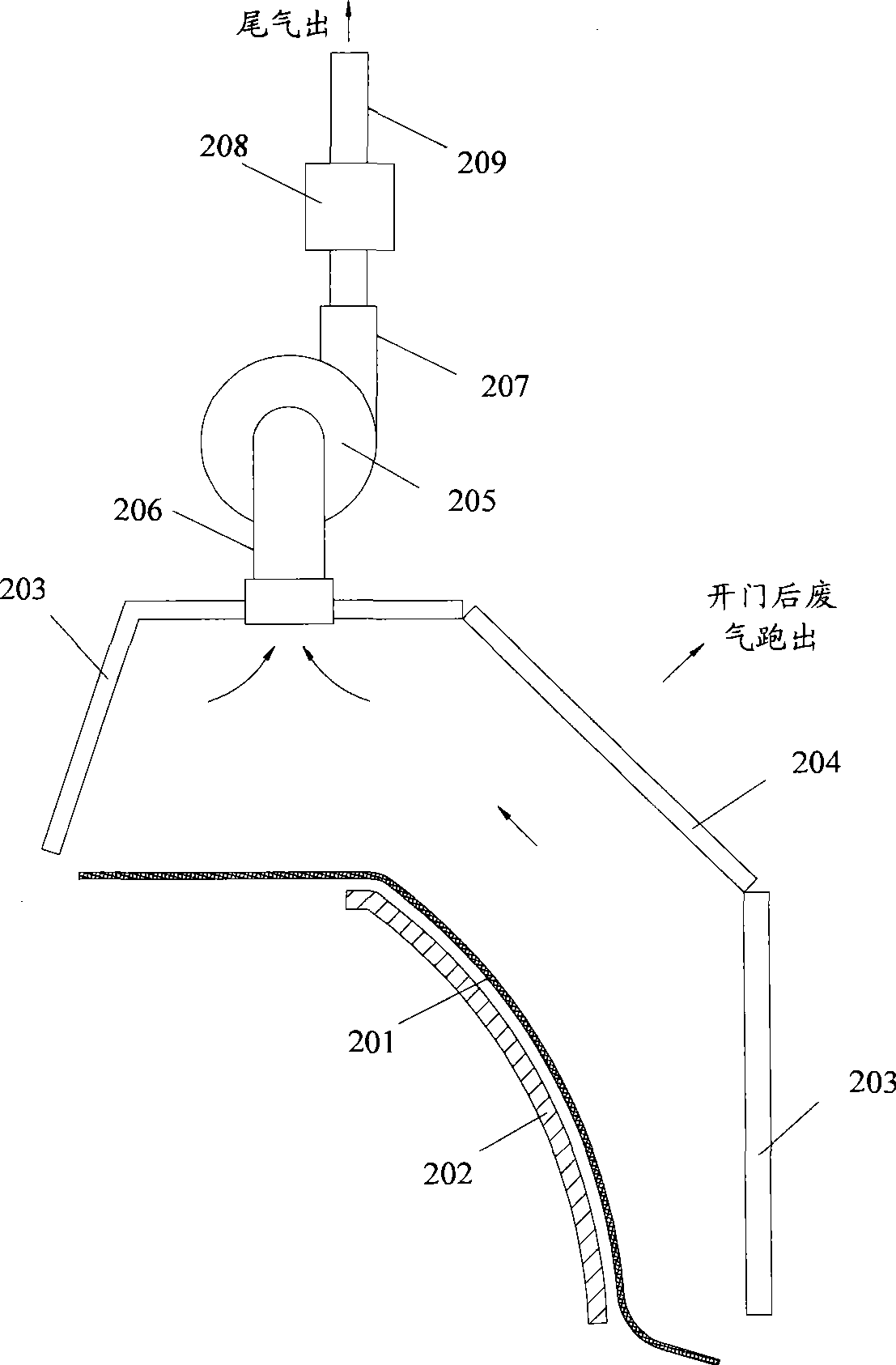

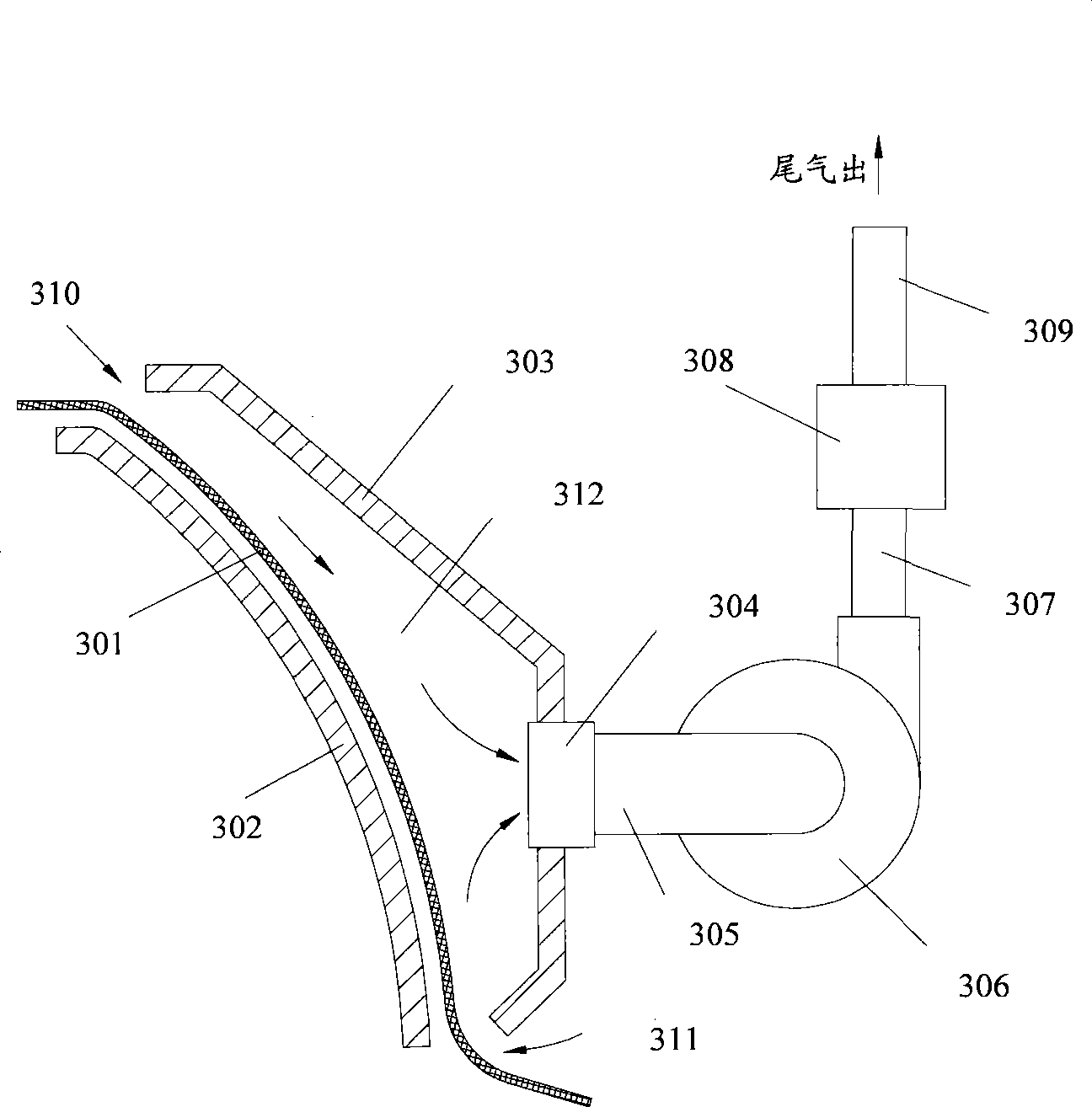

[0018] Embodiments of the present invention provide a waste gas treatment method, system, and solvent-based inkjet printer to better protect the health of operators, reduce environmental pollution, simplify the structure of the inkjet printer, reduce the space occupied by the inkjet printer, and reduce manufacturing costs. Each will be described in detail below.

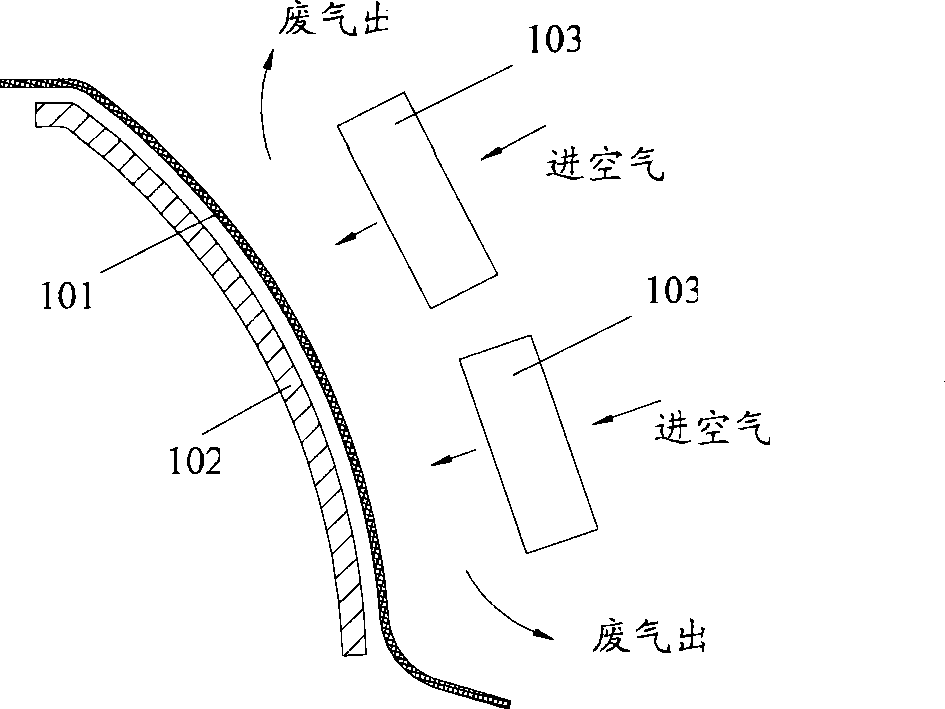

[0019] Embodiments of the present invention provide a waste gas treatment system and a waste gas treatment method. The waste gas treatment system has a gas collection device with an air inlet and a gas outlet in the waste gas volatilization area. The device is connected, and the negative pressure generating device is connected with the exhaust gas treatment device through the second pipeline. Under the action of the negative pressure generating device, a negative pressure chamber will be formed inside the gas collecting device, which will suck in the waste gas and discharge it through the gas outlet, and lead it into...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap