Embedded type cylindrical blast cap

An embedded, cylindrical technology, applied in the direction of chemical/physical processes, chemical instruments and methods, etc., can solve the problems of complex manufacturing process of embedded tubes, poor connection between outer tube and embedded tube, etc., and achieve simple structure , easy to fix, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

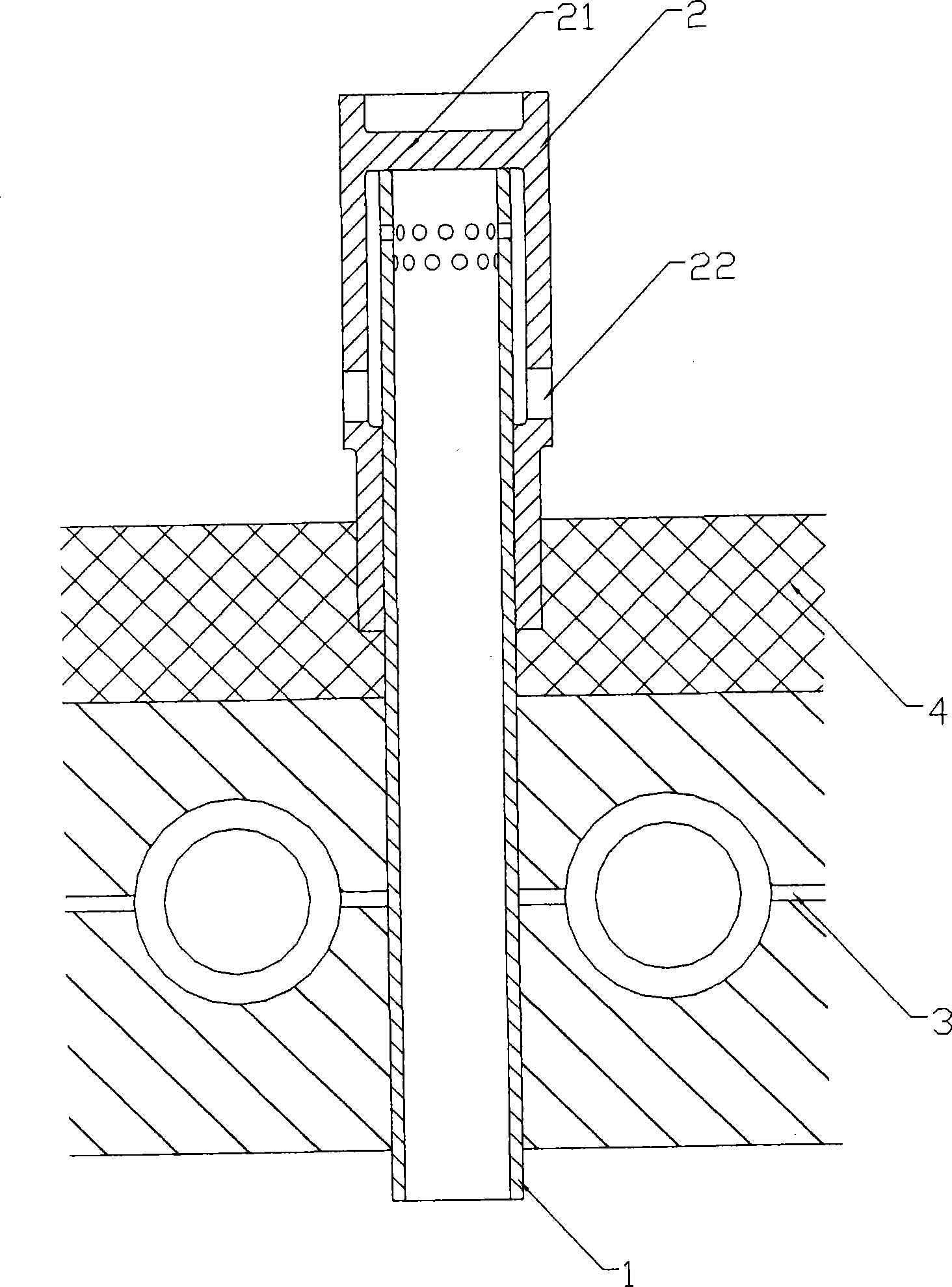

[0014] The principle of the embedded cylindrical hood provided by the present invention is:

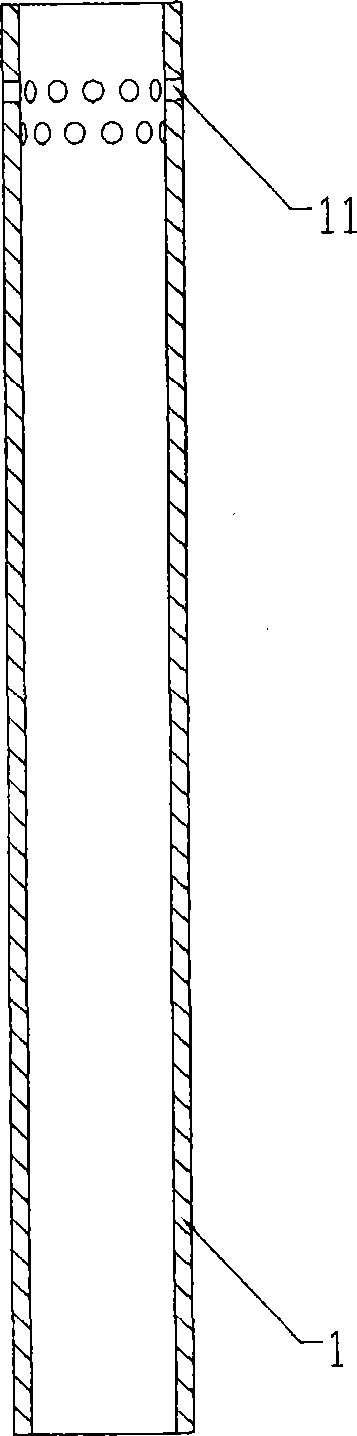

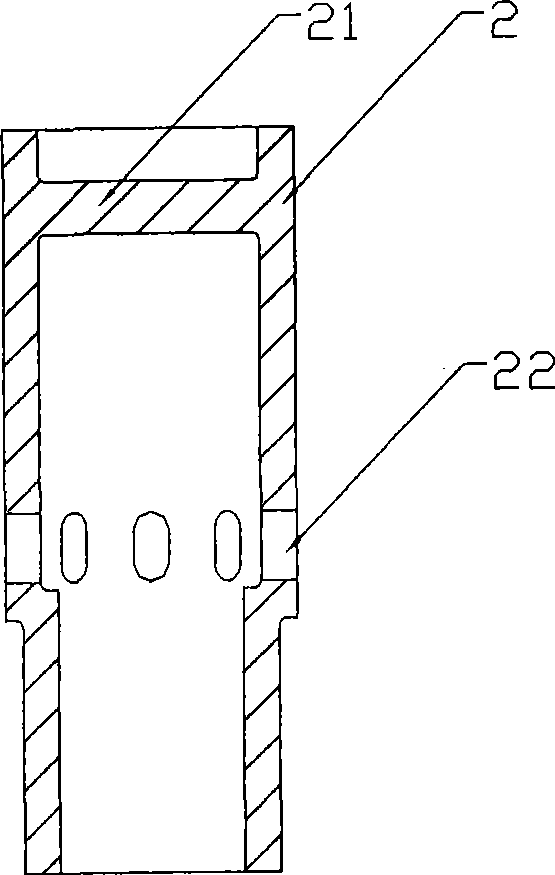

[0015] The outer sleeve is directly buckled on the inner tube, and the top of the inner tube is in close contact with the lower surface of the outer sleeve top surface, as the mutual position limitation of the two. As a result, the limit ring on the embedded pipe is canceled, the structure of the embedded pipe is simplified, and the embedded pipe can be directly made of steel pipe, and the manufacture of the embedded pipe can be completed only by simple processing of the steel pipe, which greatly simplifies the construction of the embedded pipe. The manufacturing process of the embedded tube saves the manufacturing cost of the hood.

[0016] In order to fix the outer casing and prevent the outer casing from being blown off during operation, the bottom of the outer casing is located below the upper surface of the refractory material of the air distribution plate. Material, the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com