Method for preparing wood bamboo composite floor

A wood-bamboo composite and production method technology, which is applied in the manufacture of veneer, manufacturing tools, wood processing appliances, etc., can solve the problems of unfavorable environmental protection of solid wood composite floors, skipped silk on the floor surface, and large wood consumption, and achieves the promotion of The effect of increasing fiscal revenue, increasing added value, and increasing enterprise efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

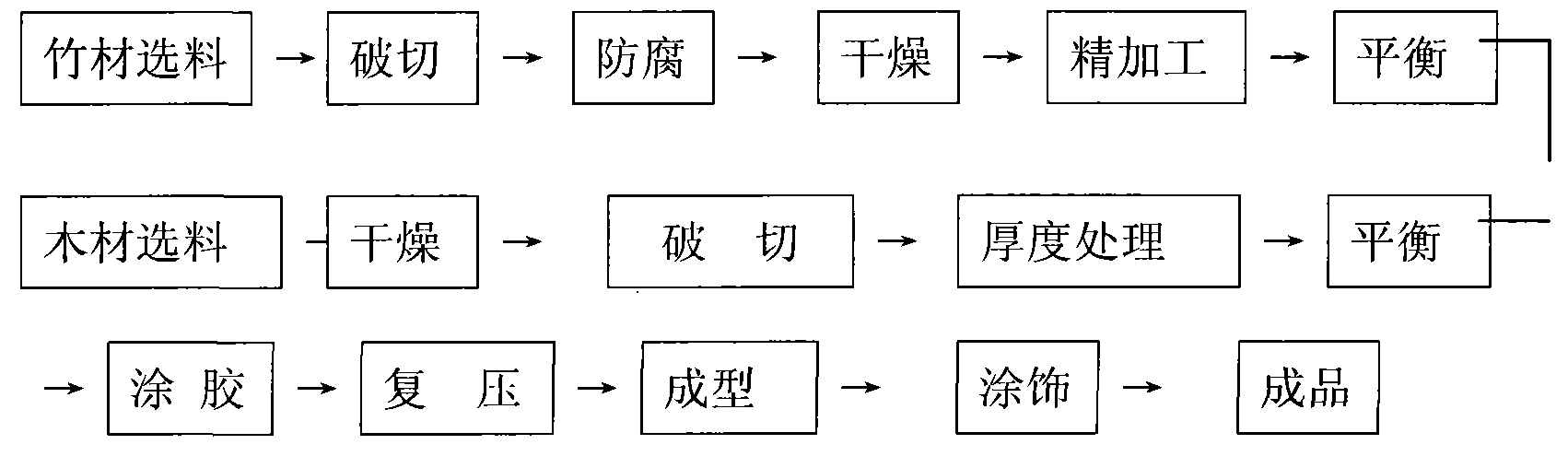

Image

Examples

Embodiment Construction

[0048] A method for making wood-bamboo composite flooring, comprising the following processing steps:

[0049] (1) Bamboo material selection: select perennial fresh moso bamboo, remove corrosion, insect change, and damaged parts, and cut into sections according to the specification length for use;

[0050] (2) Cutting:

[0051] a. Cut the bamboo section of the same specification into bamboo slices or bamboo shreds according to the specifications, and then select and remove unqualified bamboo slices or shreds;

[0052] b. Mechanically remove the blue and yellow of the qualified bamboo chips or shreds to achieve preliminary smoothness;

[0053] c. Classify and bundle bamboo slices or bamboo threads that are relatively consistent in shape, color, internode length, etc., and stack them for later use;

[0054] (3) Anti-corrosion treatment: anti-corrosion treatment adopts two carbonization treatments:

[0055] a. Carbonization for the first time: Put the cut bamboo chips or bambo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com