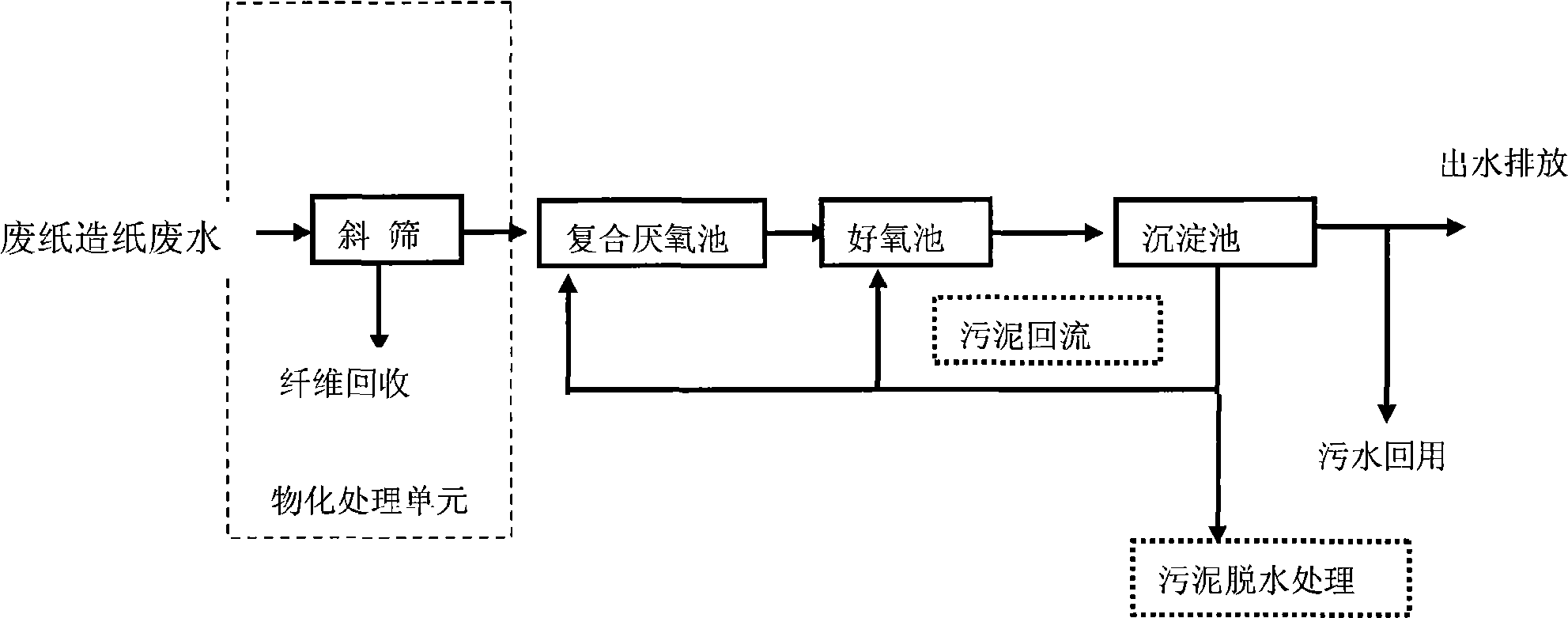

Composite anaerobic-aerobic process for treating waste paper making wastewater

A waste paper making and composite anaerobic technology, applied in aerobic and anaerobic process treatment, paper making, paper machine and other directions, can solve the problems of affecting promotion, unstable operation, difficult management, etc., to improve the overall effect and reduce the filter. The effect of material knotting and convenient operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

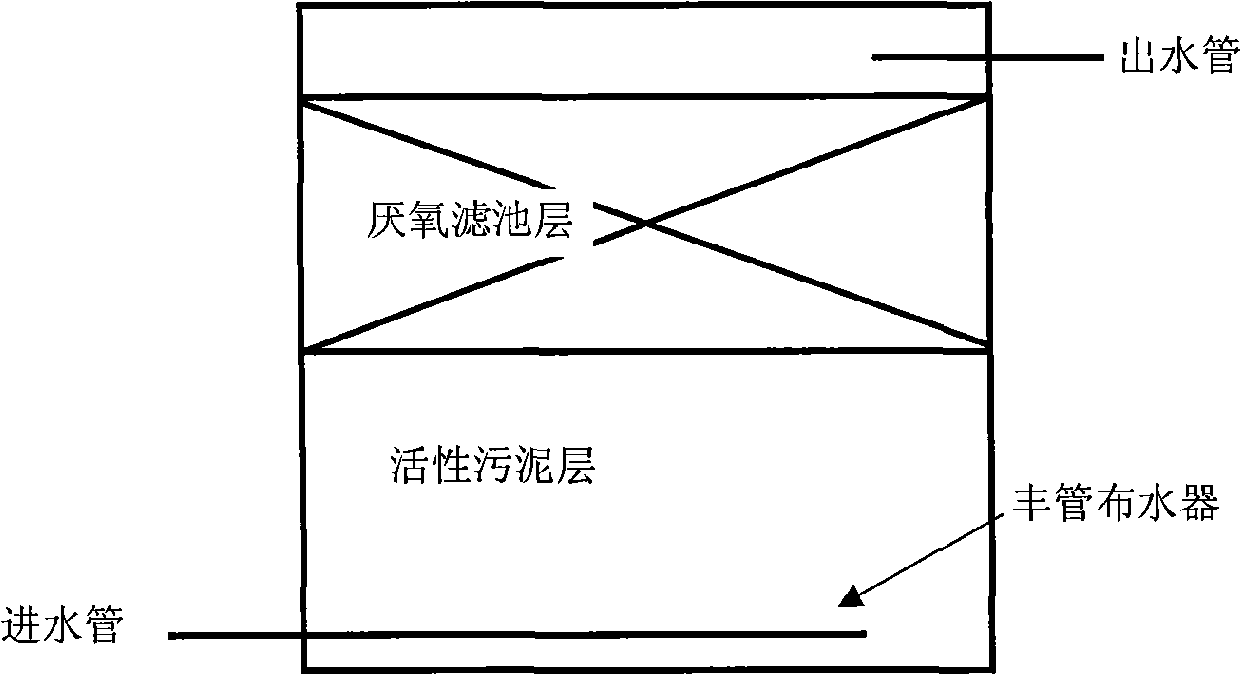

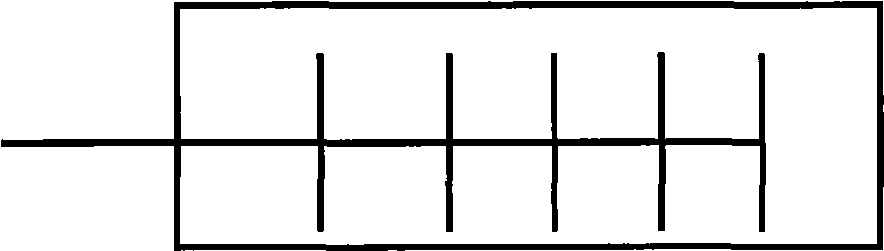

[0019] COD cr The waste paper and papermaking wastewater with an average of 800mg / L first enters the physical and chemical treatment unit, and the coarse fiber in the waste paper and papermaking wastewater is intercepted by the blocking effect of the mesh holes of the inclined screen, and the fibers are recycled; the effluent of the physical and chemical treatment unit passes through the composite The abundant pipe water distributor at the bottom of the anaerobic tank distributes water, and forms a granular anaerobic sludge layer in the activated sludge layer. The average particle size of the anaerobic sludge is 1.0 mm, and the pH value is 6.5. The hydraulic retention time of the sludge layer is 1.0 hours; through the upper anaerobic filter layer, the microorganisms attached to the surface of the filter material and the inside of the pores are used for catabolism. The filter material is a highly elastic porous polyurethane filler, and its components are: poly 50 parts by weigh...

Embodiment 2

[0021] COD cr The waste paper and papermaking wastewater with an average of 4200mg / L first enters the physical and chemical treatment unit, and the coarse fiber in the waste paper and papermaking wastewater is intercepted by the blocking effect of the mesh holes of the inclined screen, and the fibers are recycled; the effluent of the physical and chemical treatment unit passes through the composite The abundant pipe water distributor at the bottom of the anaerobic tank distributes water, and forms a granular anaerobic sludge layer in the activated sludge layer. The average particle size of the anaerobic sludge is 3.0 mm, and the pH value is 6.5. The hydraulic retention time of the sludge layer is 3.5 hours; through the upper anaerobic filter layer, the microorganisms attached to the surface of the filter material and the inside of the pores are used to decompose and metabolize. The filter material is a highly elastic porous polyurethane filler, and its components are: polymer ...

Embodiment 3

[0023] COD cr The waste paper and papermaking wastewater with an average of 2540mg / L first enters the physical and chemical treatment unit, and the coarse fiber in the waste paper and papermaking wastewater is intercepted by the blocking effect of the mesh holes of the inclined screen, and the fibers are recycled; the effluent of the physical and chemical treatment unit passes through the composite The water distribution device at the bottom of the anaerobic tank distributes water and forms a granular anaerobic sludge layer in the activated sludge layer. The average particle size of the anaerobic sludge is 2.9mm and the pH value is 7.2. The hydraulic retention time of the sludge layer is 2.35 hours; through the upper anaerobic filter layer, the microorganisms attached to the surface of the filter material and the inside of the pores are used to decompose and metabolize. The filter material is a highly elastic porous polyurethane filler, and its components are: polymer 90 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com