Sludge cutting machine

A cutting machine and sludge technology, which is applied in dehydration/drying/concentrated sludge treatment, grain treatment, etc., can solve the problem of ineffective crushing of solid materials, and achieve the wide use of equipment, large processing capacity, and low operation and maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

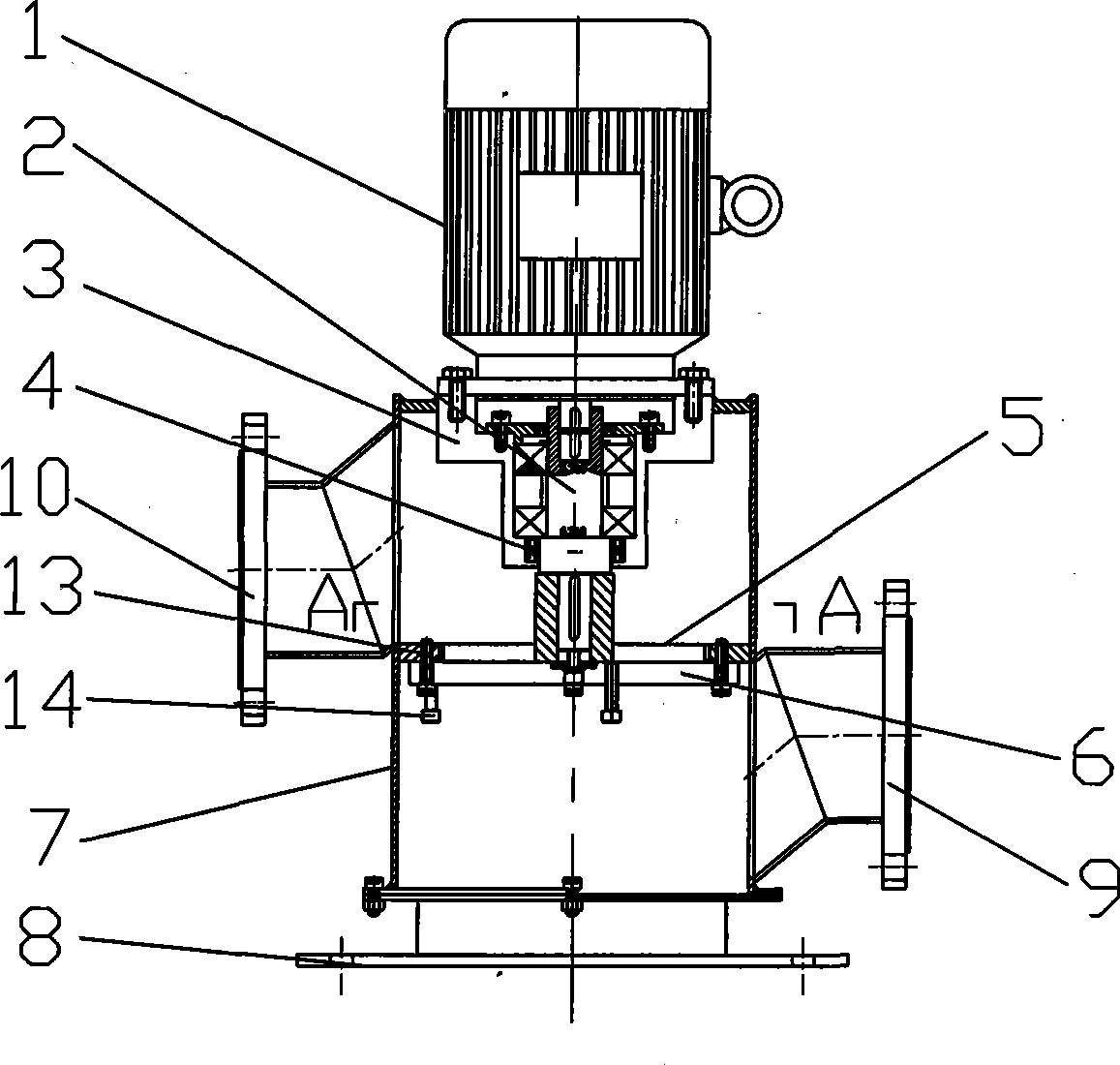

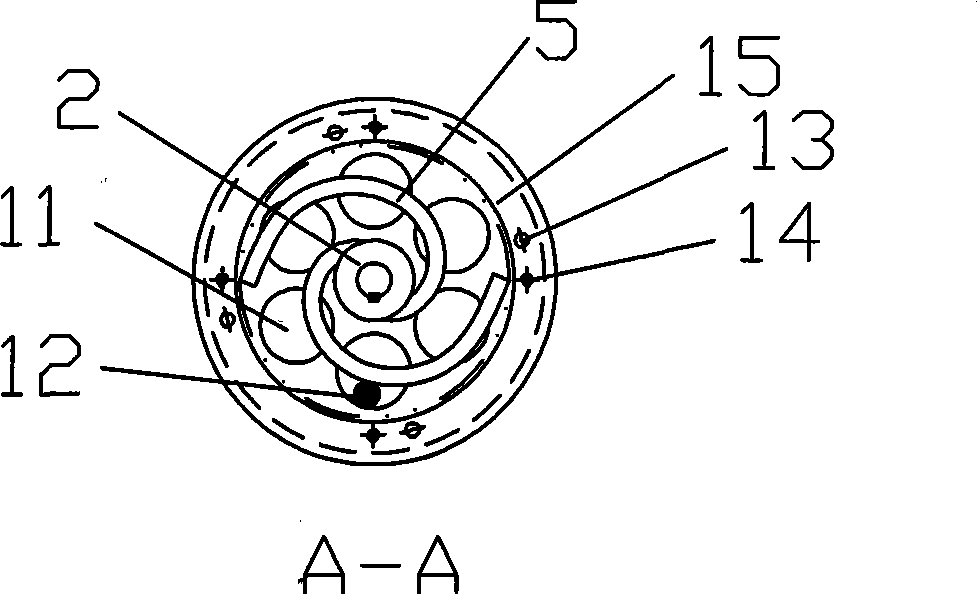

[0013] Such as figure 1 , 2 As shown, a sludge cutting machine includes a cutting cylinder 7 with a material inlet 9 at the bottom and a discharge opening 10 at the top, a bearing seat 3 and a motor 2 arranged at the top of the cutting cylinder 7, and a motor 2 arranged at the top of the cutting cylinder 7 The cutting ring 15 in the middle and the adjustable position knife seat 6 connected thereto; the motor 1 is connected with the blade 5 through the drive shaft 2. Described blade 5 is a spiral blade. For a better cutting effect, it is best to use an Archimedes spiral blade and a symmetrically arranged double blade.

[0014] The adjustable position knife seat is that the knife seat 6 and the cutting ring 15 are connected by bolts 13, and an adjusting screw 14 is set on the cutting ring 15, and the end of the adjusting screw 14 bears on the knife seat 6. There are 3 or 4 uniformly distributed adjusting screws on the material cutting ring for coupling and adjustment.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com