Formaldehyde absorbing tower dealcoholizing technology

A formaldehyde absorption tower and methanol technology, which is applied in the fields of oxidative preparation of carbonyl compounds, organic chemistry, separation/purification of carbonyl compounds, etc., can solve the problems of methanol content fluctuation, high production cost, low conversion rate, etc., to increase economic benefits, The effect of reducing process cost and reducing unit consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0035] The invention is improved on the basis of the traditional silver method formaldehyde technology.

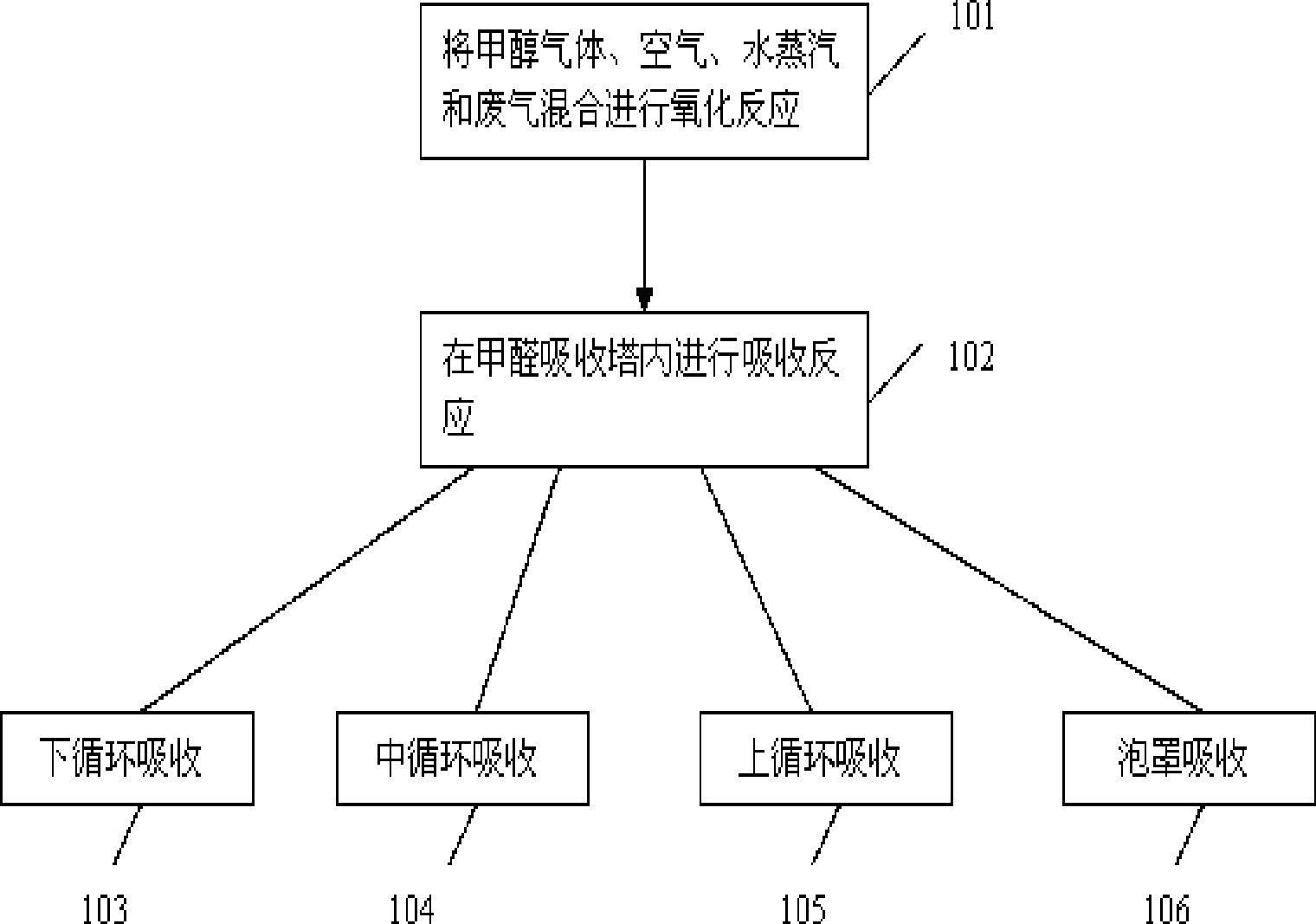

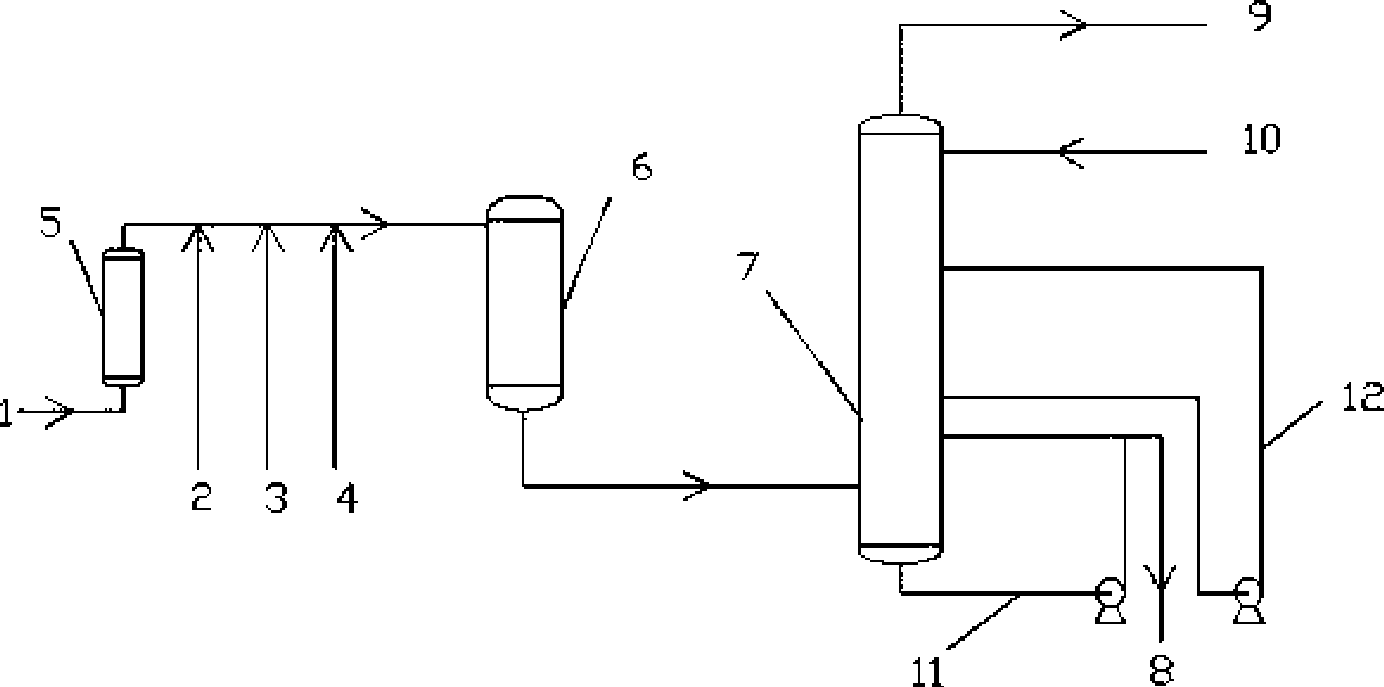

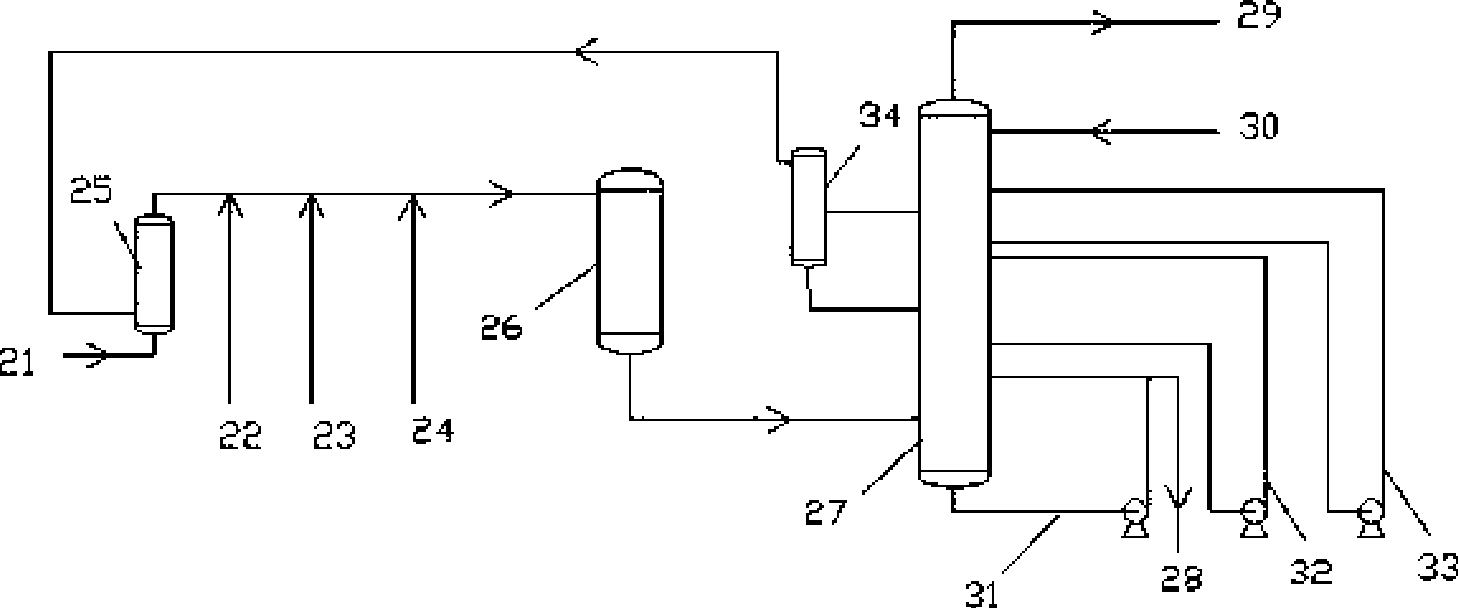

[0036] Such as figure 1 and image 3 As shown, compared with the traditional silver-based formaldehyde process, the new process is basically the same as the traditional process in the formaldehyde oxidation process. The specific steps are as follows:

[0037] Step 101: an oxidation reaction process after mixing methanol gas 21 , air 22 , steam 23 and aldehyde-containing waste gas 24 quaternary gas.

[0038] Methanol gas 21 is vaporized after being heated in methanol evaporator 25 and the pressure is controlled to be about 0.05MPa. Methanol gas enters the gas mixer according to the set flow rate and is mixed with air 22, steam 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap