Method for producing microalloy ferro-silicon by using a ferrous metasilicate electric stove integral deoxidation and reduction

A ferrous silicate and microalloying technology, applied in the direction of improving process efficiency, can solve the problems of comprehensive utilization of nickel smelting waste slag, waste of resources, etc., and achieve the goal of reducing emissions, reducing production power consumption, and reducing production costs Effect

Inactive Publication Date: 2011-01-05

牛庆君

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This is not only a huge waste of resources, but also shows that nickel smelting waste slag has great development and utilization value. However, the comprehensive utilization of nickel smelting waste slag has actually become a worldwide problem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention relates to a method for producing microalloy ferro-silicon by using a ferrous metasilicate electric stove integral deoxidation and reduction, including the steps as follows: a. heating a nickel smelting waste slag or a nickel, copper and cobalt smelting waste slag to a molten state, or fetching the nickel smelting waste slag or a nickel, copper and cobalt smelting waste slagof the molten state to place in a thermal slag ladle directly; b. holding the slag in the molten state by heat insulation, at the same time infusing oxygen or air into the waste slag to react to generate solid residue to purify; c removing the solid residue; d. cooling the remained part and then crushing; e. producing the ferro-silicon through the deoxidation and reduction of the remained part asiron raw material and other raw material. For the method of the invention, firstly the nickel smelting waste slag is purified, then the purified copper smelting waste slag may be used to replace the iron raw material such as steel shaving, iron scale, sintered ball cluster and the like for the ferro-silicon production, thus it is capable of reducing the dosage of dinas rock or rock quartz; it hasbeen found that the ferro-silicon (FeSi75) produced by the method meets the national standard completely; the invention provides a novel method for producing ferroalloy.

Description

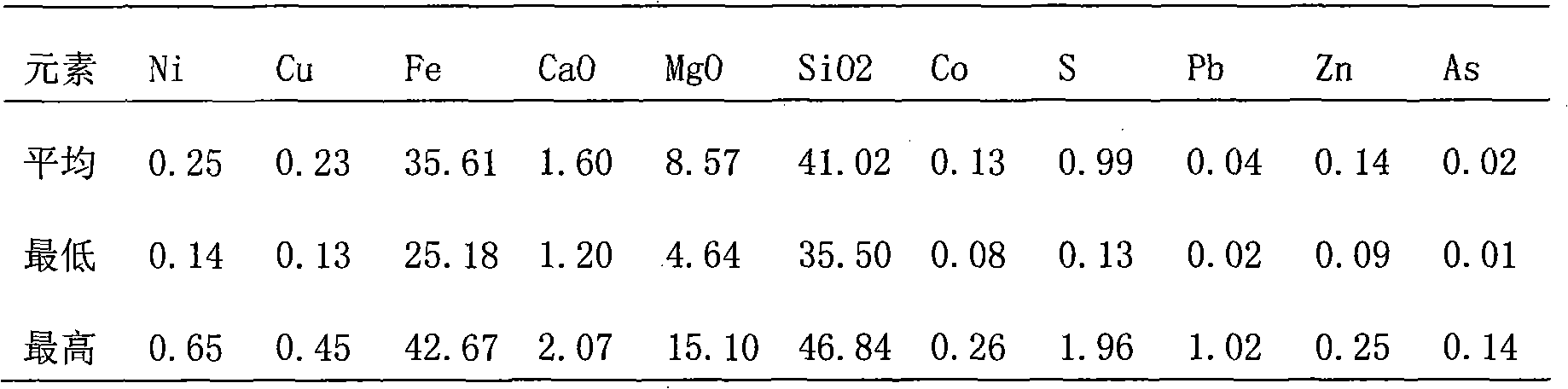

Method for producing microalloyed ferrosilicon by integral deoxidation reduction of ferrous silicate electric furnace Technical field The invention relates to a technology for comprehensive utilization of non-ferrous metal smelting waste slag (nickel smelting waste slag, copper smelting waste slag, nickel, copper, cobalt smelting waste slag), and particularly relates to a method for producing microalloyed silicon by using ferrous silicate electric furnace for overall deoxidation and reduction The iron method. Background technique Nickel smelting slag and nickel, copper, and cobalt smelting slag are smelting slag discharged from nickel smelting production, which is a kind of industrial solid waste. With the development of production, solid waste is increasing year by year. A huge amount of nickel smelting slag is stored in the open air in the slag yard around the smelting enterprise. Except for a very small amount for the cement plant as an additive (instead of iron ore), most ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22B4/06C22C35/00

CPCY02P10/20

Inventor 牛庆君王振峰

Owner 牛庆君

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com