Generator provided with switching catalytic combustion gas turbine

A catalytic combustion and gas turbine technology, which is applied to gas turbine devices, machines/engines, mechanical equipment, etc., can solve the problems of large heat transfer area, small flow loss, and stable combustion of low calorific value gas for power generation and utilization

Inactive Publication Date: 2011-01-05

SHANGHAI JIAO TONG UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The regenerative small gas turbine invented by the China Aviation Power Machinery Research Institute [Patent Publication No. CN10128076] performs heat energy exchange through a corrugated plate heat exchanger. The unit volume heat transfer area is large, the flow loss is small, and the heat recovery efficiency can reach 0.7-0.95; small The thermal efficiency of the gas turbine can reach 35-50%. This gas turbine uses a corrugated plate heat exchanger, and the fuel is fuel oil instead of using low-calorific-value gas, which does not solve the problem of stable combustion and power generation of low-calorific-value gas.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

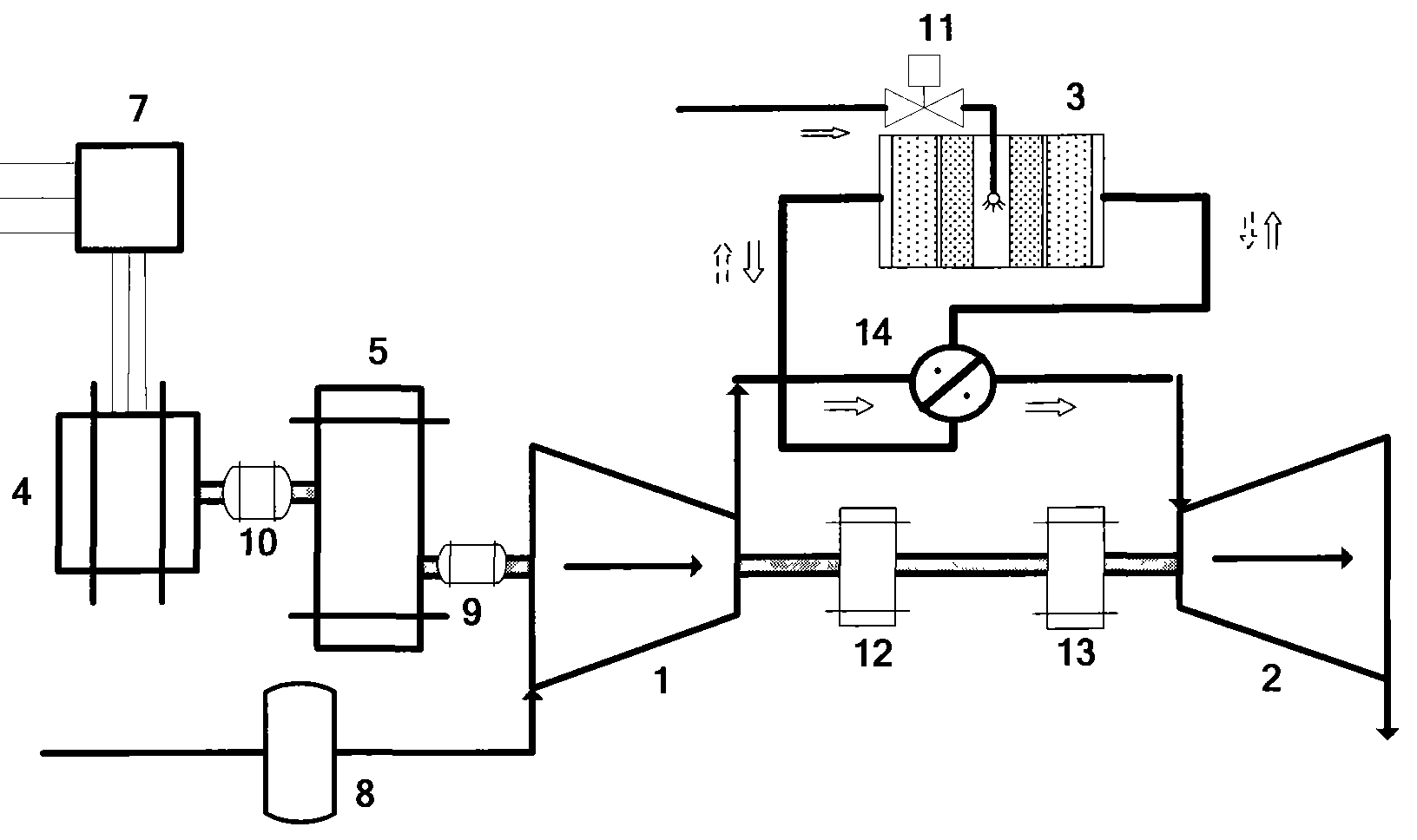

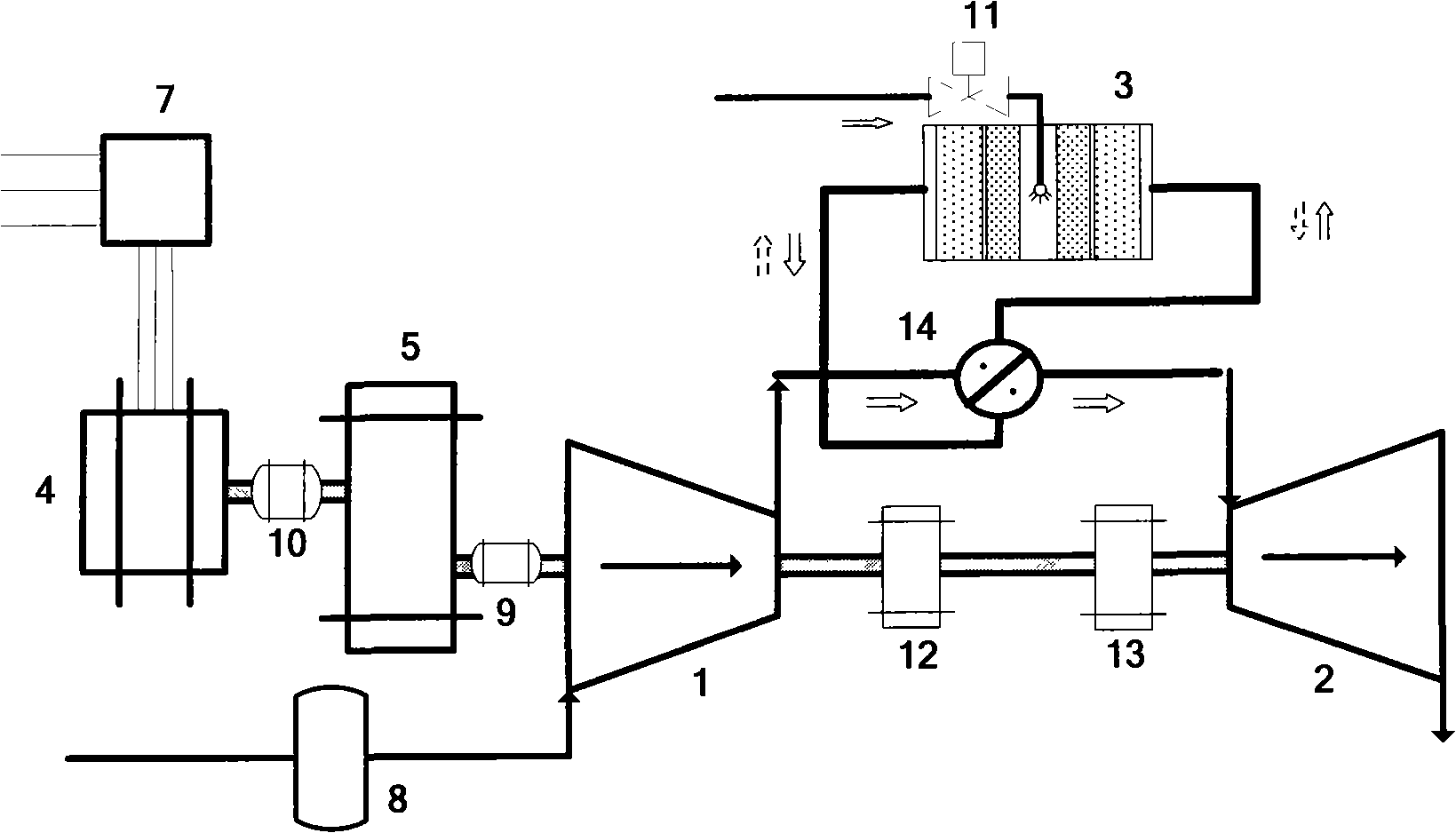

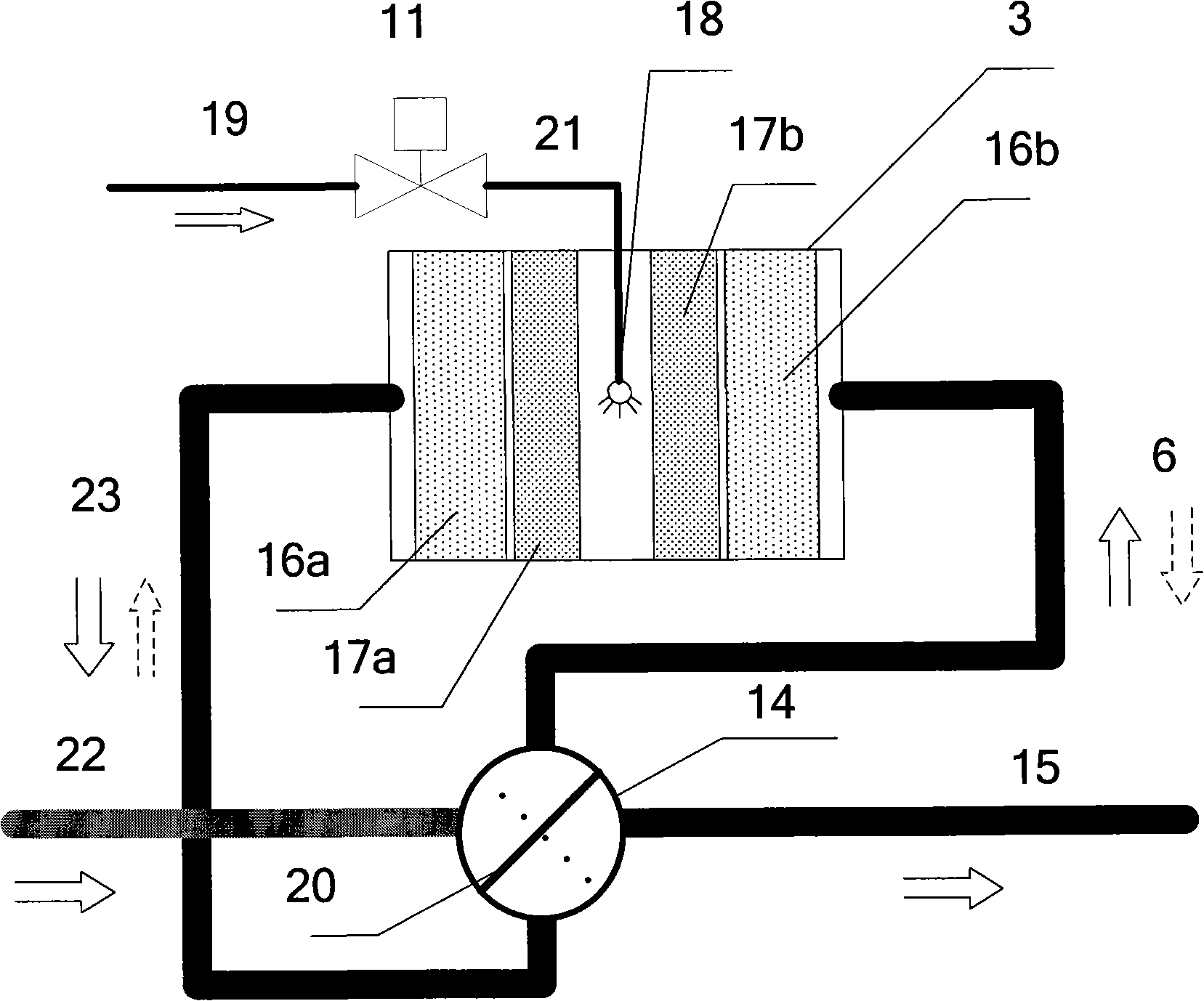

The invention discloses a generator provided with a switching catalytic combustion gas turbine in the technical field of dynamic power generation, wherein the outlet and the inlet of an air filter are connected with low calorific value fuel gas, the outlet of the air filter is connected with the inlet of a centrifugal compressor, the outlet of the centrifugal compressor is connected with the inlet of a four-way valve, the outlet of the four-way valve is connected with one end of a catalytic combustion chamber, a heat accumulator at the other end of the catalytic combustion chamber enters a centripetal turbine, the outlet of the centripetal turbine is connected with the atmosphere directly, a flam ignitor is started and inserted in a cavity of the catalytic combustion chamber, the centrifugal compressor is coaxial with the centripetal turbine, an output shaft at the centrifugal compressor end is connected with a high-speed shaft of a reduction gear box through a shaft coupling, and a low-speed shaft of the reduction gear box is connected with a generator shaft through the shaft coupling. The fuel net content of the low calorific value fuel gas adopted by the generator is less than 5 percent and the heat value of the low calorific value fuel gas is lower than 2 MJ / NM3, and the generator adopts catalytic combustion so that the fuel gas is usually exhausted into the atmosphere directly, and not only the energy is used but also the discharge of greenhouse gas is reduced.

Description

Switching Catalytic Combustion Gas Turbine Power Plants technical field The present invention relates to a power generation device in the technical field of power generation, in particular to a switching catalytic combustion gas turbine power generation device. Background technique The calorific value of low-calorific gas is less than 5MJ / Nm3, with a wide variety and a huge amount, including mine ventilation gas, some coalbed methane and biomass gas, and by-products with very low methane (CH4) concentrations in steel and chemical industries Gas, a large part of which is ultra-low calorific value gas less than 2MJ / Nm3, and the concentration of methane (CH4) is only 0.5% to 5%. Due to the low concentration of methane, it cannot be ignited and burned by conventional methods, and it is quite difficult to use it in practice. Most of the ultra-low calorific value fuels are discarded, and the waste of energy is astonishing. The total amount of methane emitted into the atmosphere...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F02C6/18

Inventor 翁史烈翁一武王玉璋巩斌

Owner SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com