Comprehensive test-bed

A comprehensive test bench and calibrator technology, applied in the field of test benches, can solve problems such as low efficiency, unfavorable development of modern shipbuilding technology for final assembly, and impact on shipbuilding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

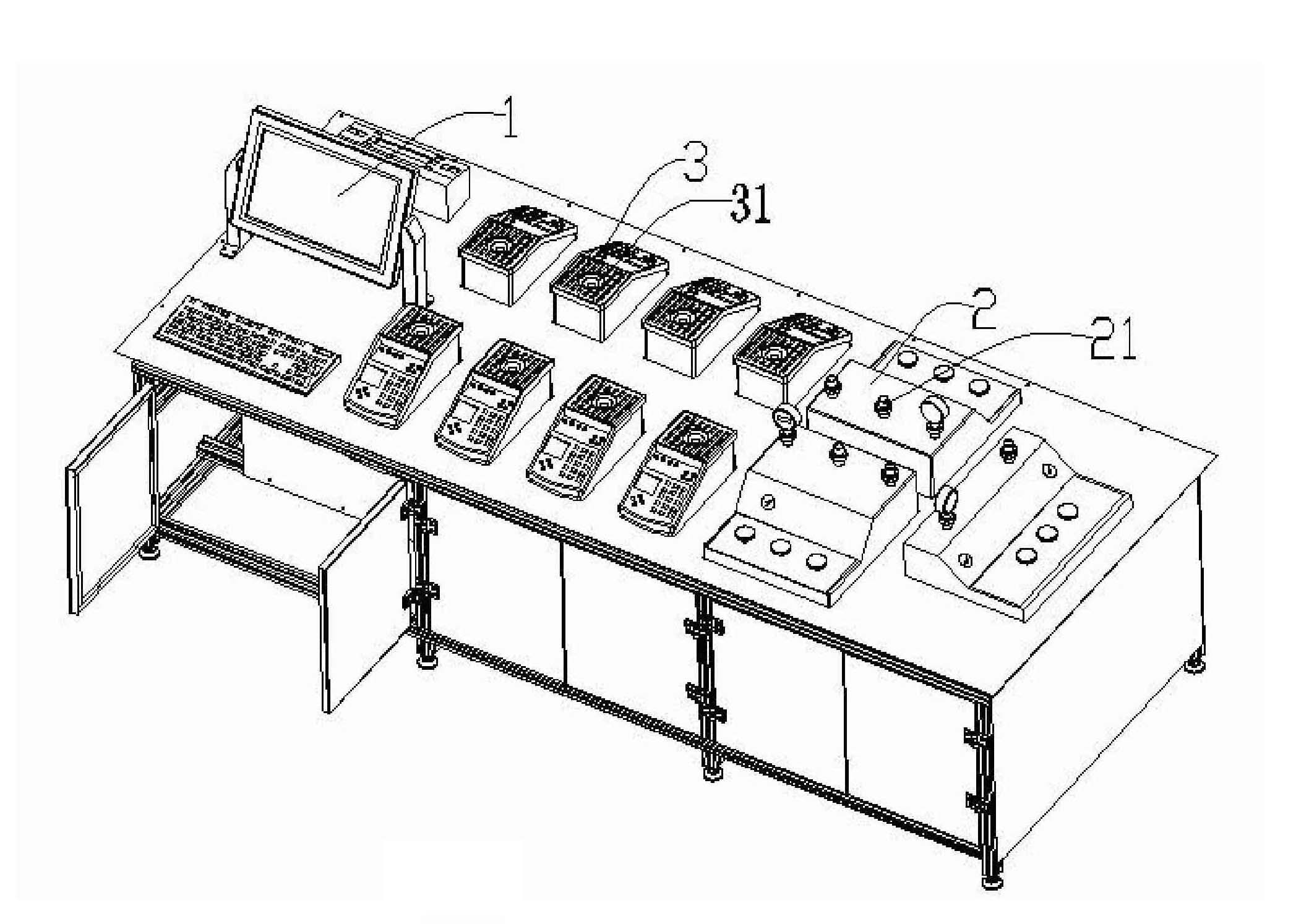

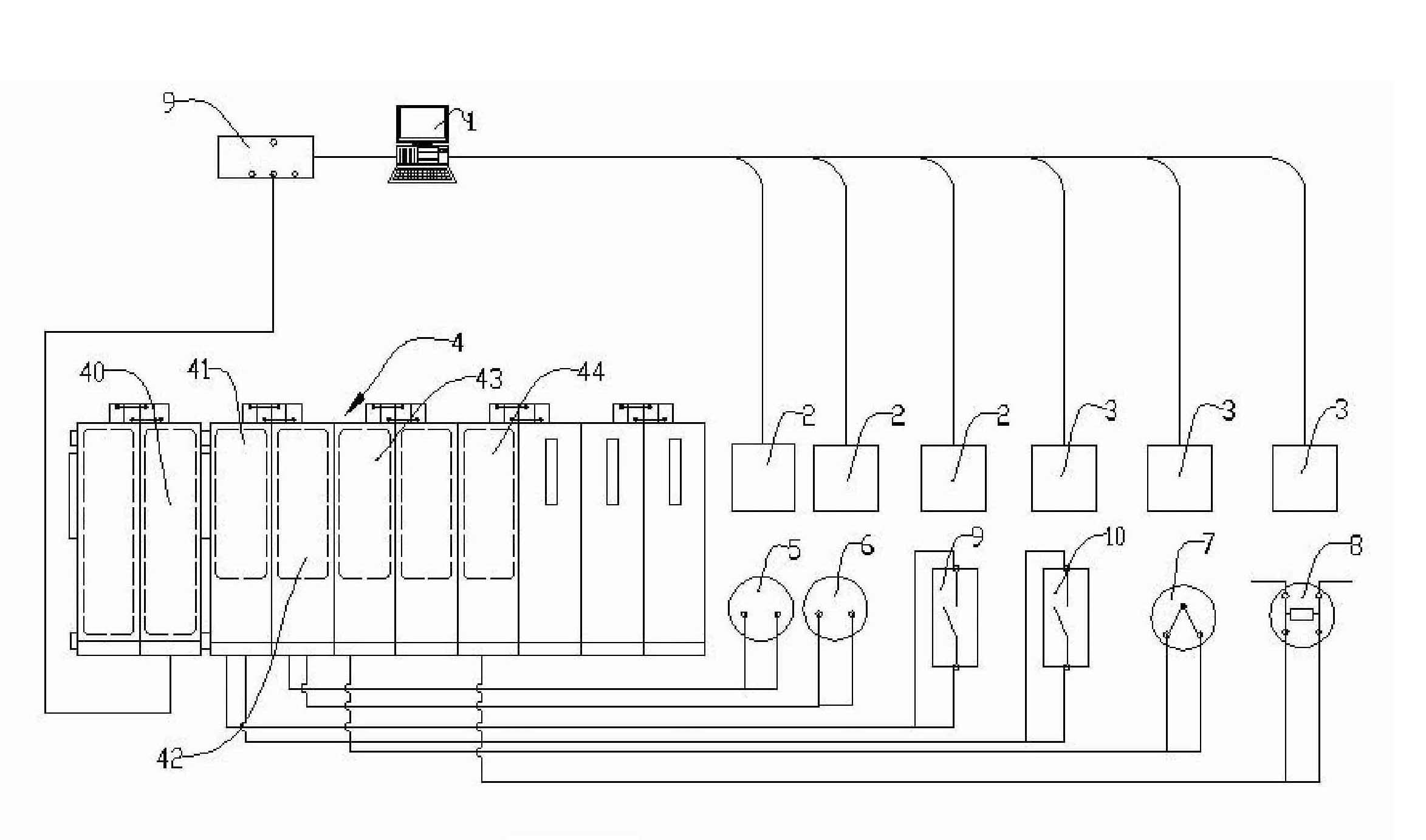

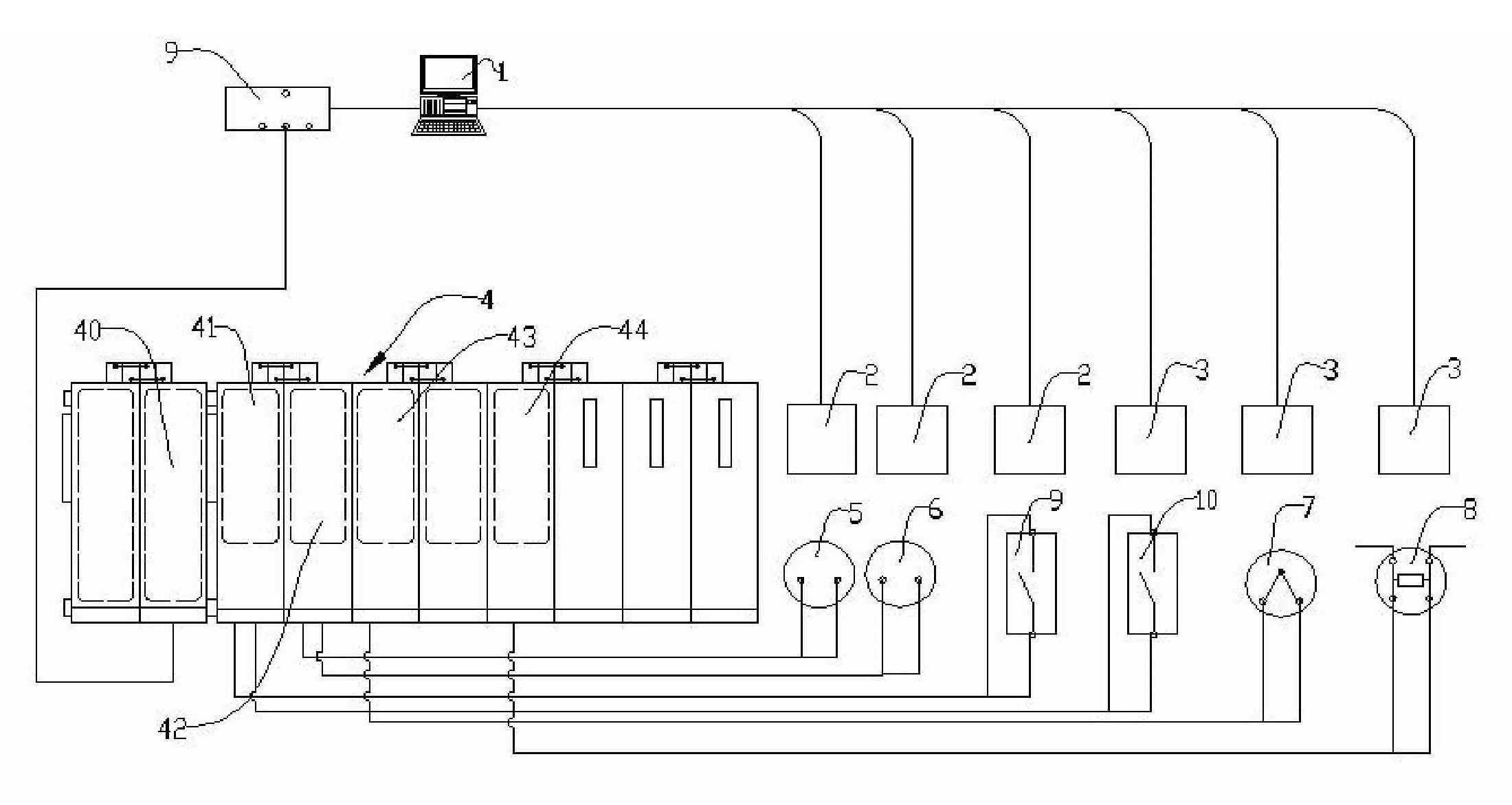

[0014] A comprehensive test bench such as figure 1 , figure 2 , including a computer 1, the computer is respectively connected to the pressure calibrator 2 and the temperature calibration tank 3 through each serial / parallel port of the multi-serial port card, and the computer is also connected to a PLC controller 4 through a data line, and the PLC controller contains a digital input module 41. Current analog input module 42, thermocouple input module 43, thermal resistance input module 44, and controller 40. The pressure calibrator 2 is equipped with a pressure transmitter 5 or a liquid level transmitter 6 for sensing The pressure connection port 21, the current analog input module 41 of the PLC controller 4 has a connection terminal that can be electrically connected to the pressure transmitter 5 or the liquid level transmitter 6, and the temperature calibration tank 3 has a heat supply The detection groove 31 of the detection temperature that resistance sensor 8 or thermoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com