High power light emitting diode module package structure

A light-emitting diode and module packaging technology, used in semiconductor devices, electrical components, circuits, etc., can solve the problems of poor adhesion, inability to meet users, and expensive LED module manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

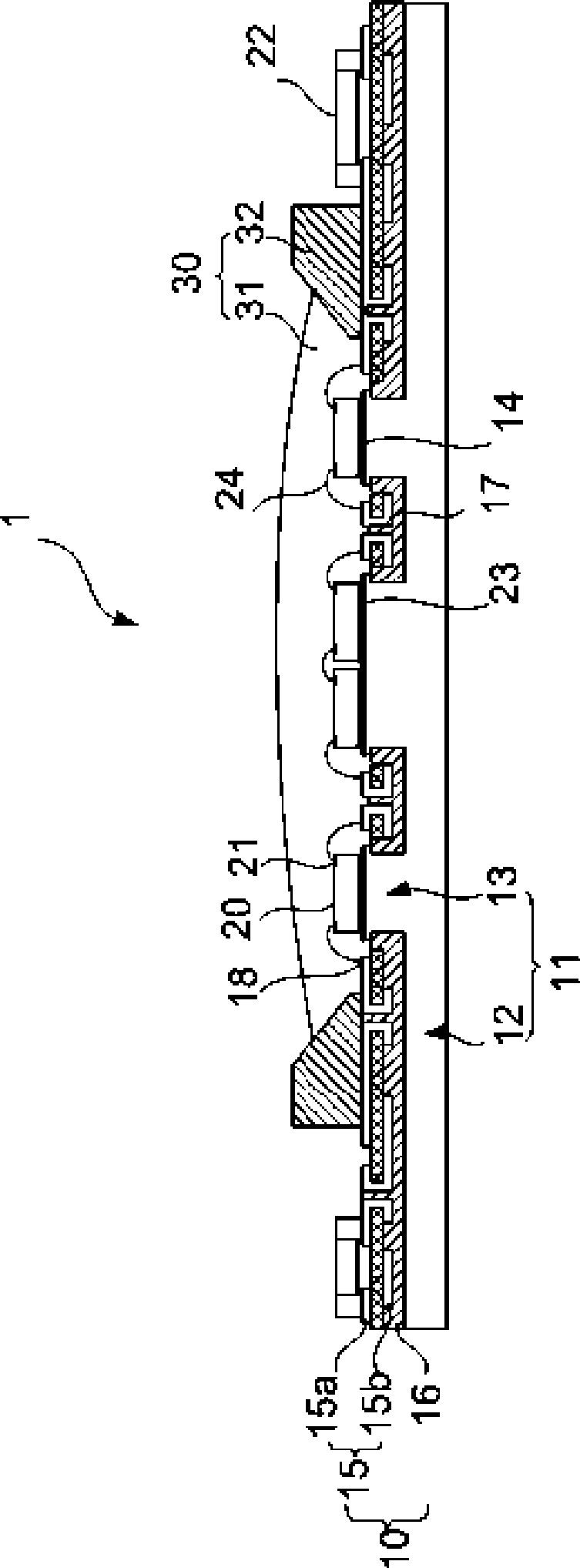

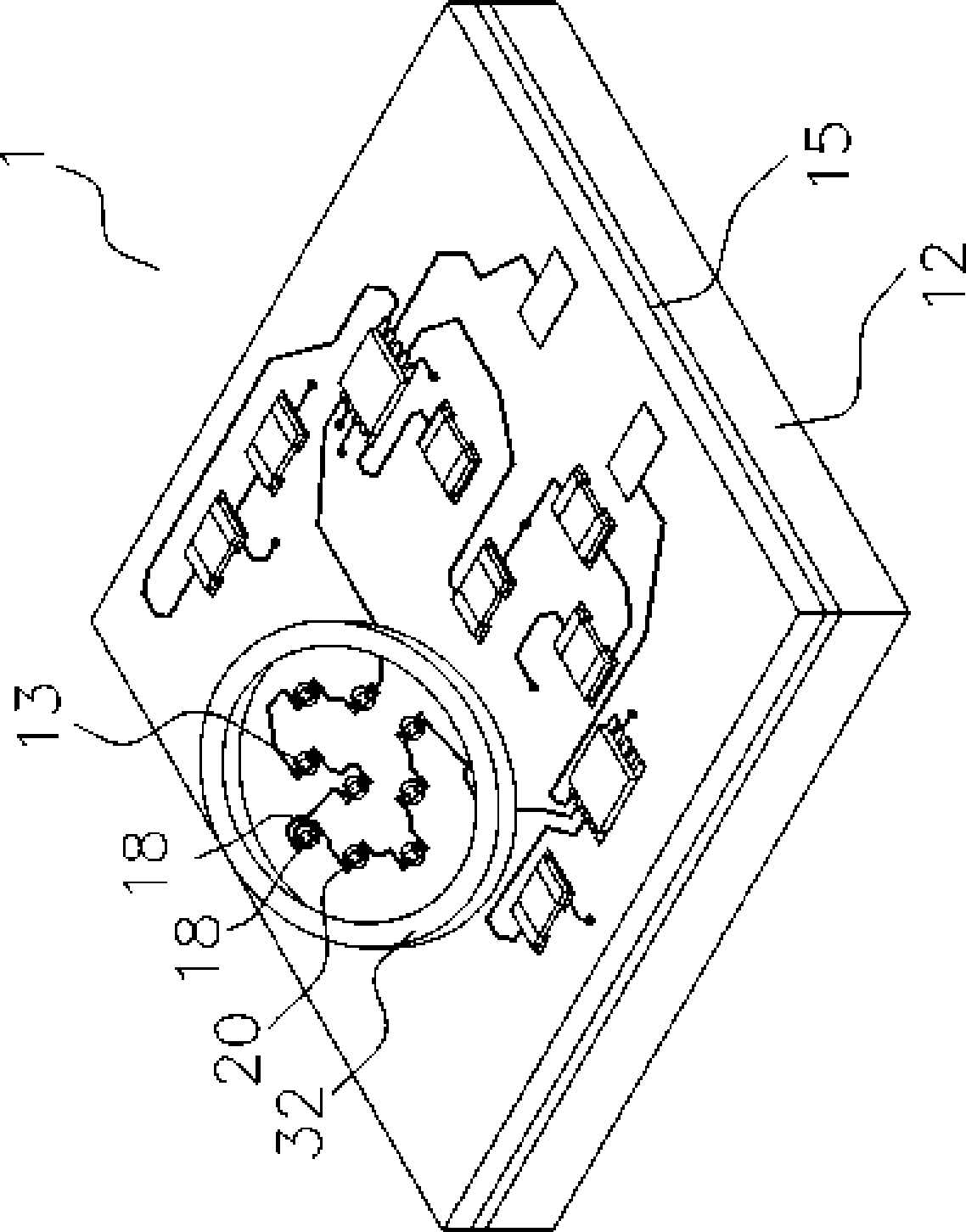

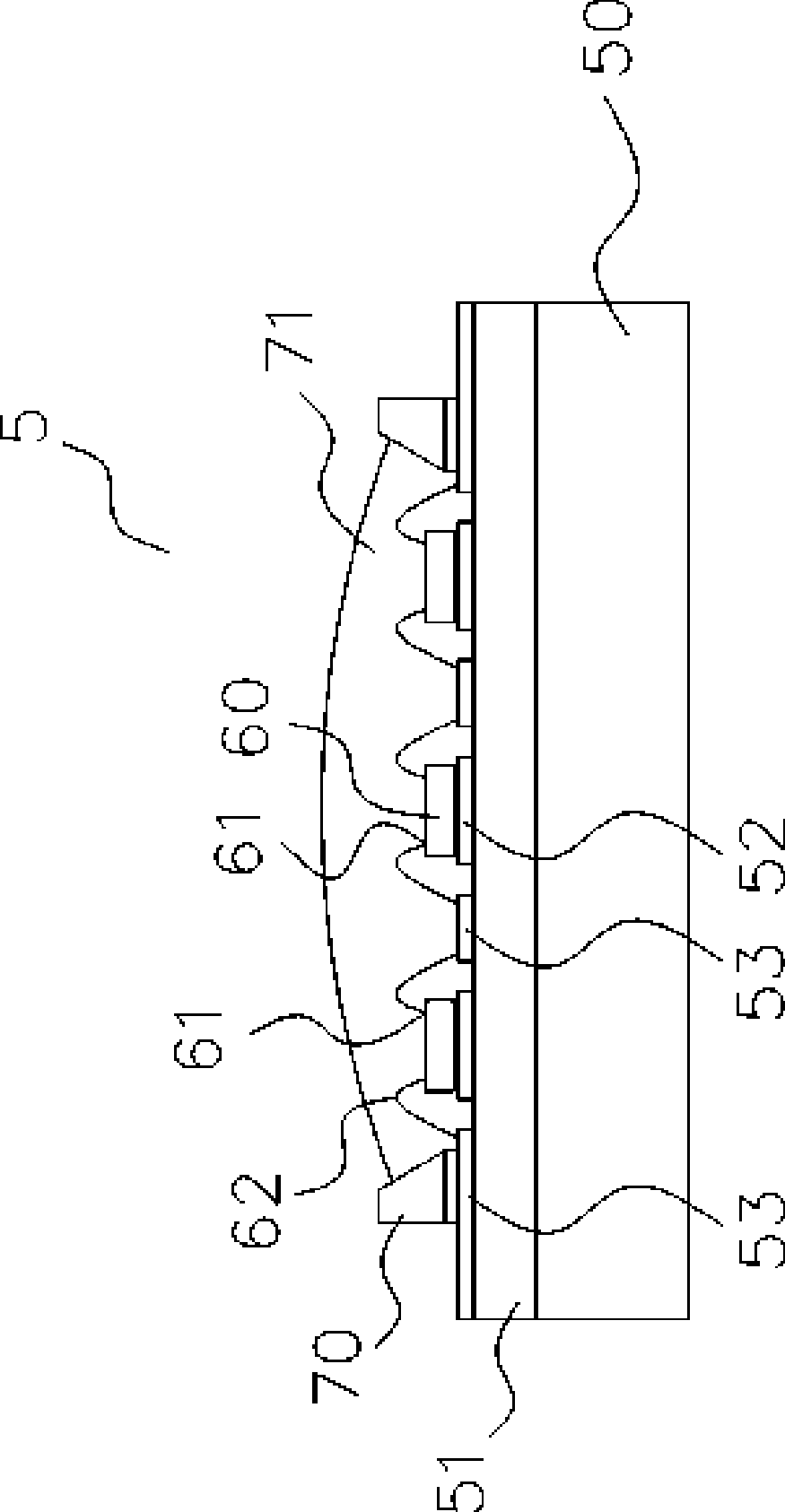

[0046] The invention relates to a high-power LED module packaging structure, which at least includes a substrate, a LED and an insulating casing.

[0047] The substrate includes a heat dissipation base and a multi-layer circuit. The heat dissipation base includes a base and at least one component joint post protruding from the base. The surface of the component joint post is smaller than the surface of the base, so that The component bonding post is directly bonded to the light-emitting diode, and the multi-layer circuit is pressed on the base with the raised component bonding post as the core and extends around, and an insulating layer is placed between the component bonding post. Bond without any gaps or other material. Wherein, the surface of the component joint post is smaller than the surface of the base; the multilayer circuit may include one or more layers of circuits, and the upper and lower circuits can be electrically connected by laser plating holes, mechanical plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com