Complete denture designing and manufacturing method based on CAD/RP technology

A technology for complete dentures and manufacturing methods, applied in calculation, diagnostic recording/measurement, medical science, etc., can solve problems such as low workload, cumbersome steps, and complicated operations, and achieve the effect of improving efficiency and simplifying complicated procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following examples are used to illustrate the present invention, but are not intended to limit the protection scope of the present invention.

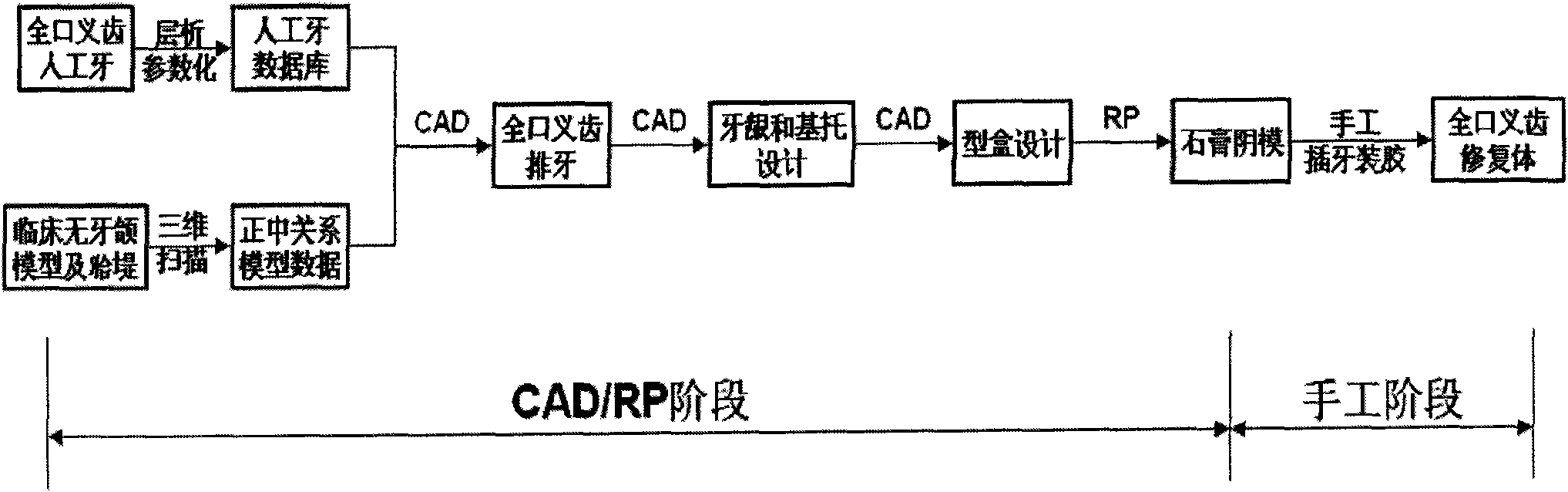

[0030] Such as figure 1 As shown, the present invention has completed a kind of " two-step method " production process of the neutral zone complete denture based on CAD / RP technology.

[0031] Method content of the present invention comprises the following steps:

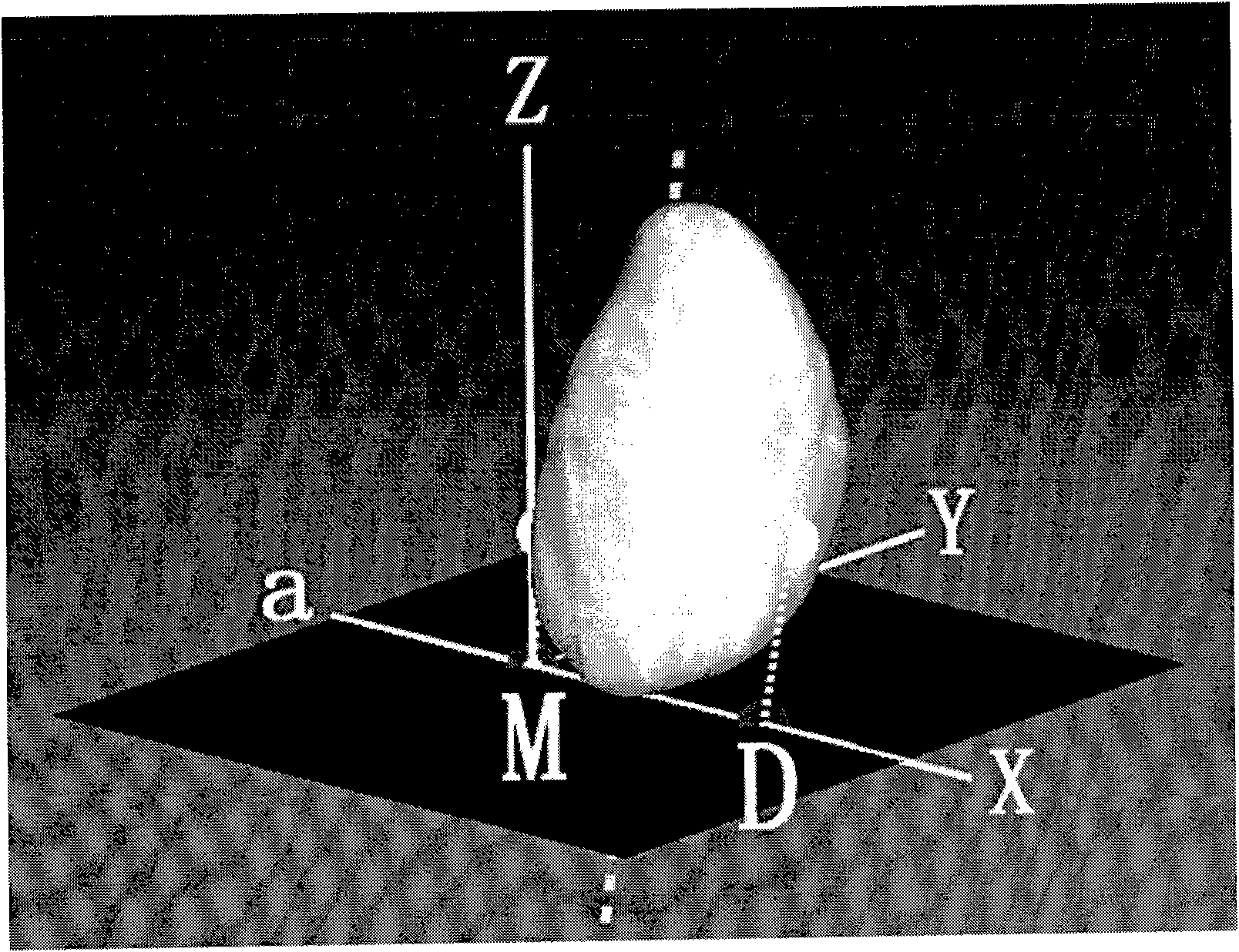

[0032] 1. The establishment of a three-dimensional graphic database of complete dentures and artificial teeth based on parametric positioning, including: acquisition of artificial teeth data, establishment of artificial teeth positioning coordinate system and each marker point, two steps.

[0033] (1) Artificial tooth data acquisition

[0034] Using silicone rubber embedding technology, the three-layer color resin artificial tooth (Heraeus Gusha Dental Co., Ltd.) was turned into a white anhydrite model, and the SB-01 chromatography machine (Beijing Times Angel B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com