Technique for floatation separation of hard washing copper zinc sulfuration mine

A sulfide ore, copper-zinc technology, applied in flotation, solid separation, etc., can solve the problems of poor ore adaptability, high cost, poor concentrate quality, etc., and achieve the effect of strong ore adaptability, reduced consumption, and high-efficiency separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

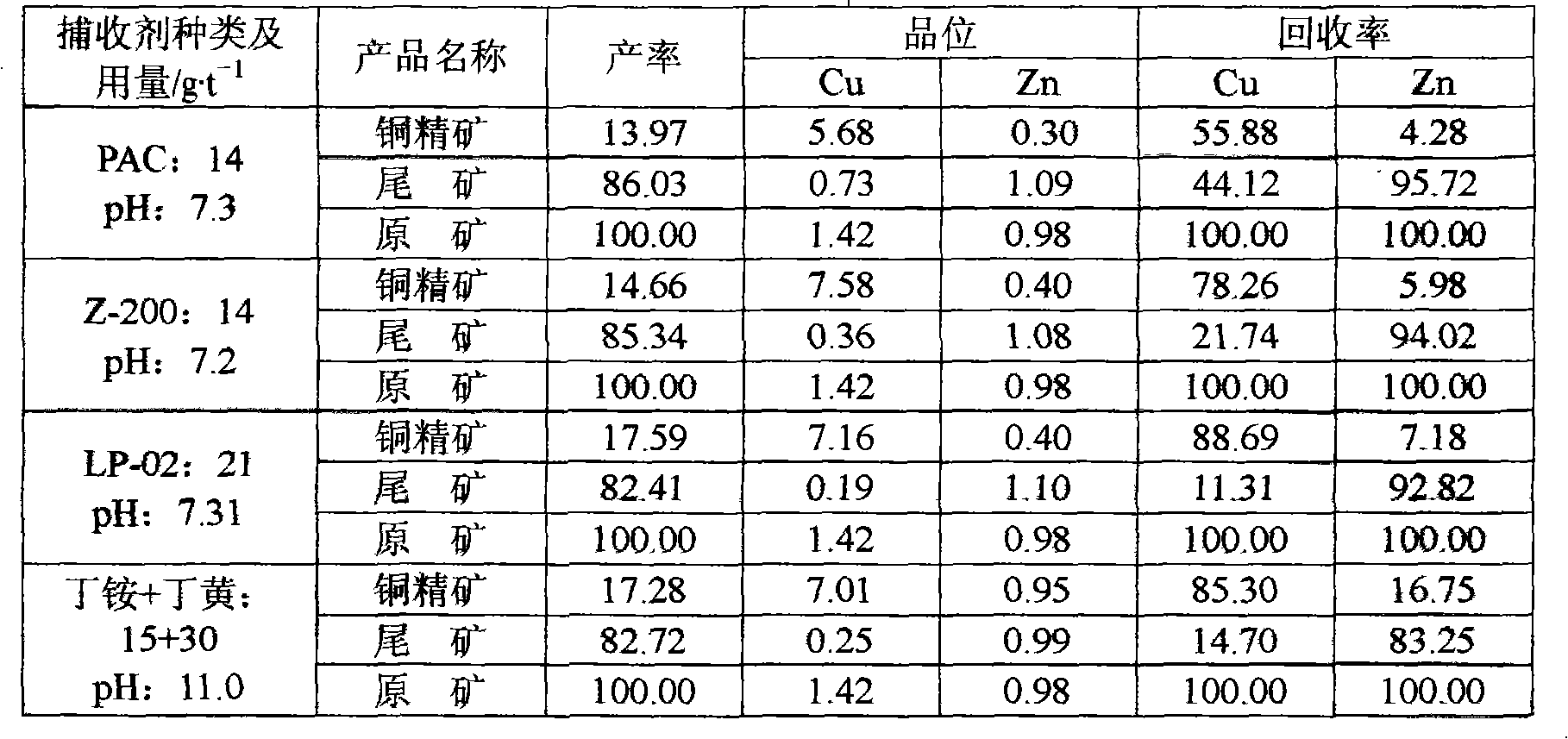

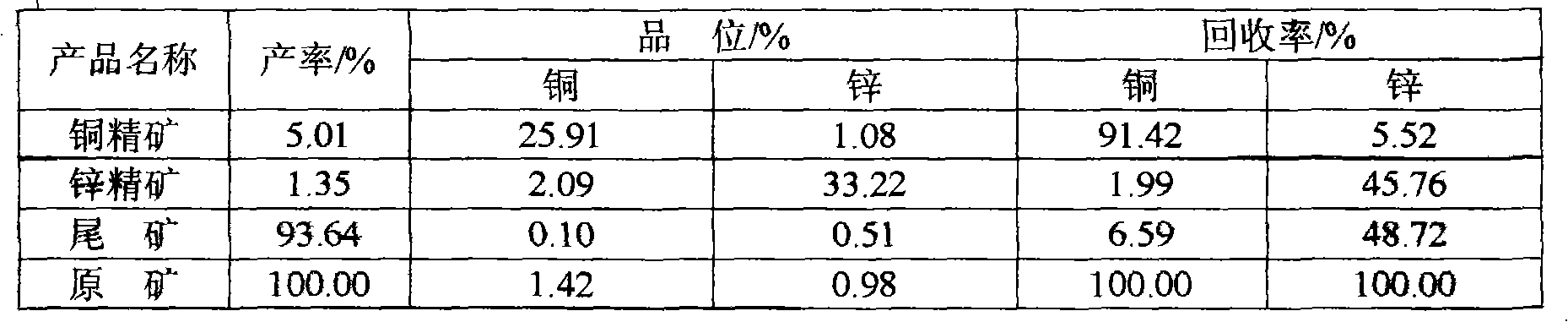

[0025] The raw ore is a copper-zinc sulfide ore with chalcopyrite and sphalerite as the main useful components, and its raw ore grade is: copper 1.42%, zinc 0.98%.

[0026] Add inhibitor LY-02720g / t during ball milling, grinding fineness -200 mesh accounts for 75%, add collector LP-0218g / t, foaming agent 2 # The oil is 7g / t, and the copper minerals are preferentially floated out. The copper minerals floated out are subjected to three blank separations, and the copper roughing bottom flows through two copper sweeps, and LP-027g / t is added each time. After copper separation, add lime 1000g / t to the pulp to adjust the pH of the pulp between 9 and 10, and add zinc activator CuSO 4 400g / t, zinc collector butyl xanthate 130g / t, foaming agent 2 # The oil is 14g / t, and the zinc minerals that emerge are subjected to four times of beneficiation. During the process of beneficiation, lime is added to adjust the pH value of the pulp between 10 and 11. Lime is added each time at 200g / t. ...

Embodiment 2

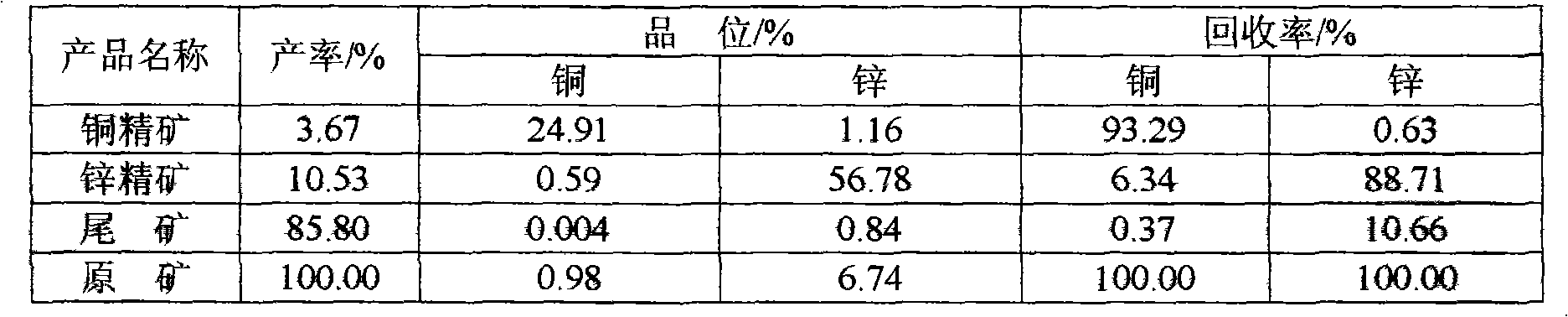

[0030] For another raw ore with different grades, the difference in the properties of the raw ore compared with Example 1 is mainly reflected in the lower grade of copper, which is 0.98%; and the higher grade of zinc, which is 6.74%, and zinc exists in the form of sphalerite. Form copper-zinc polymetallic complex refractory sulfide ore. Add inhibitor LY-02500g / t during ball milling, grinding fineness -200 mesh is 80%, add collector LP-02 21g / t, foaming agent 2 # Oil 10g / t, copper minerals are firstly floated out, and the copper rough concentrate that floats out is selected twice, and the selection adopts blank selection, and copper roughing is followed by two times of sweeping, and the dosage of one agent for sweeping is: LP-027g / t, the dosage of the second agent for scanning is: LP-023g / t. After copper separation, add lime 200g / t to the pulp to adjust the pH of the pulp between 9 and 10, add CuSO 4 210g / t is used as the activator of zinc minerals, butyl xanthate 150g / t is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com