Numerical machine tool

A CNC machine tool and a new type of technology, applied in the field of machinery, can solve the problems of large changes in the interconnected dimensions of parts, difficulty in reaching the acceptance criteria for overhaul, and gaps in transmission components, and achieve the effects of novel structure, improved precision, and high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

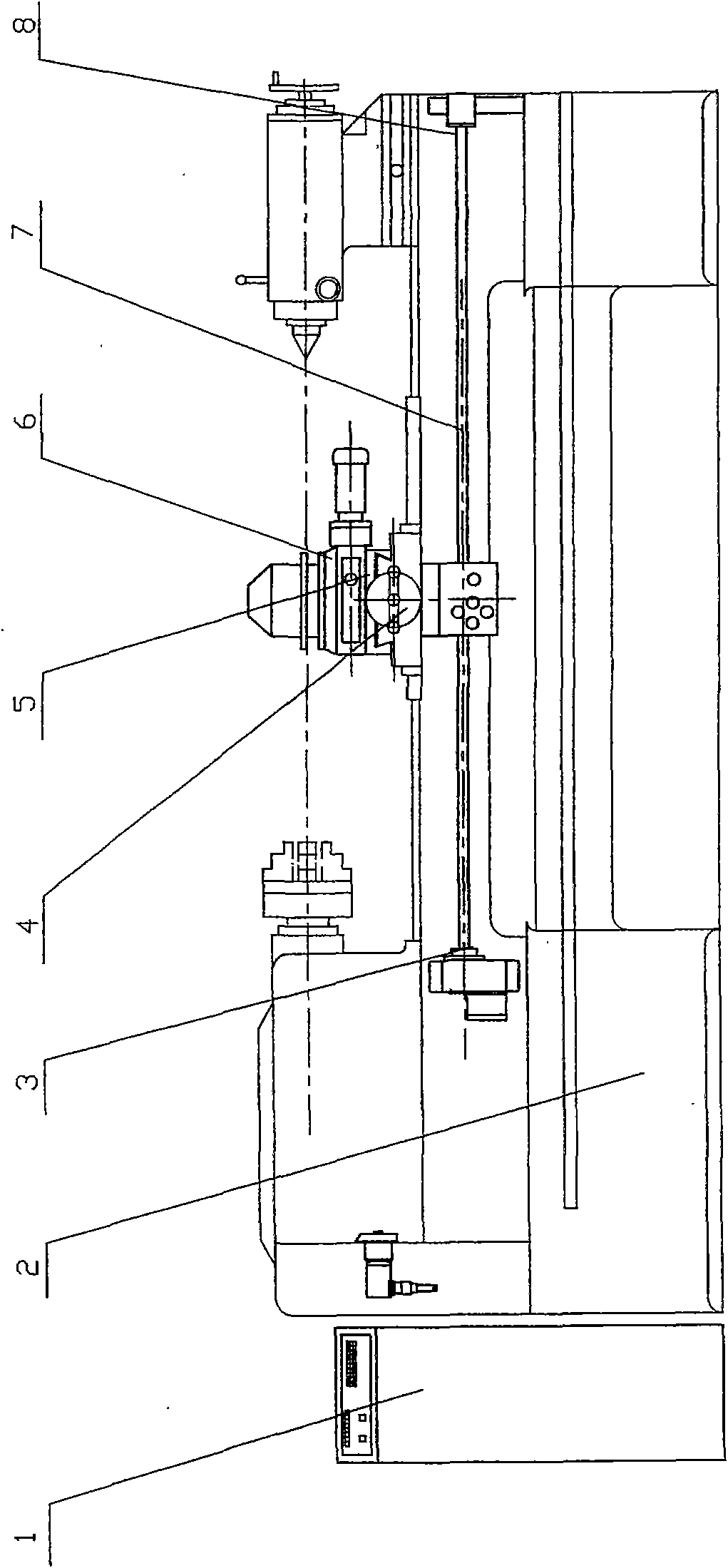

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

[0011] The number of revolutions of the spindle of the lathe and the forward and reverse control. Usually, a pulse generator is installed at the end of the main shaft to transmit the revolution information to the computer system. When processing threads and lead screws, the configured spindle pulse generator is installed coaxially, and the connection of the transmission chain is flexible. At the same time, since the spindle generator is an optical component, care should be taken during installation, and the speed should meet the requirements to avoid scrapping. Therefore, it is generally installed when processing threads, and disconnected when not in use to prolong its life.

[0012] CNC machine tools must have a precise transmission system in order to have good precision and surface quality. Considering the shortest feed tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com