Honing machine

A technology of honing machine and honing head, applied in honing machine tools, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenient transportation, hidden dangers, increased equipment structure, etc., and achieve convenient operation, improved processing efficiency and reasonable layout. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

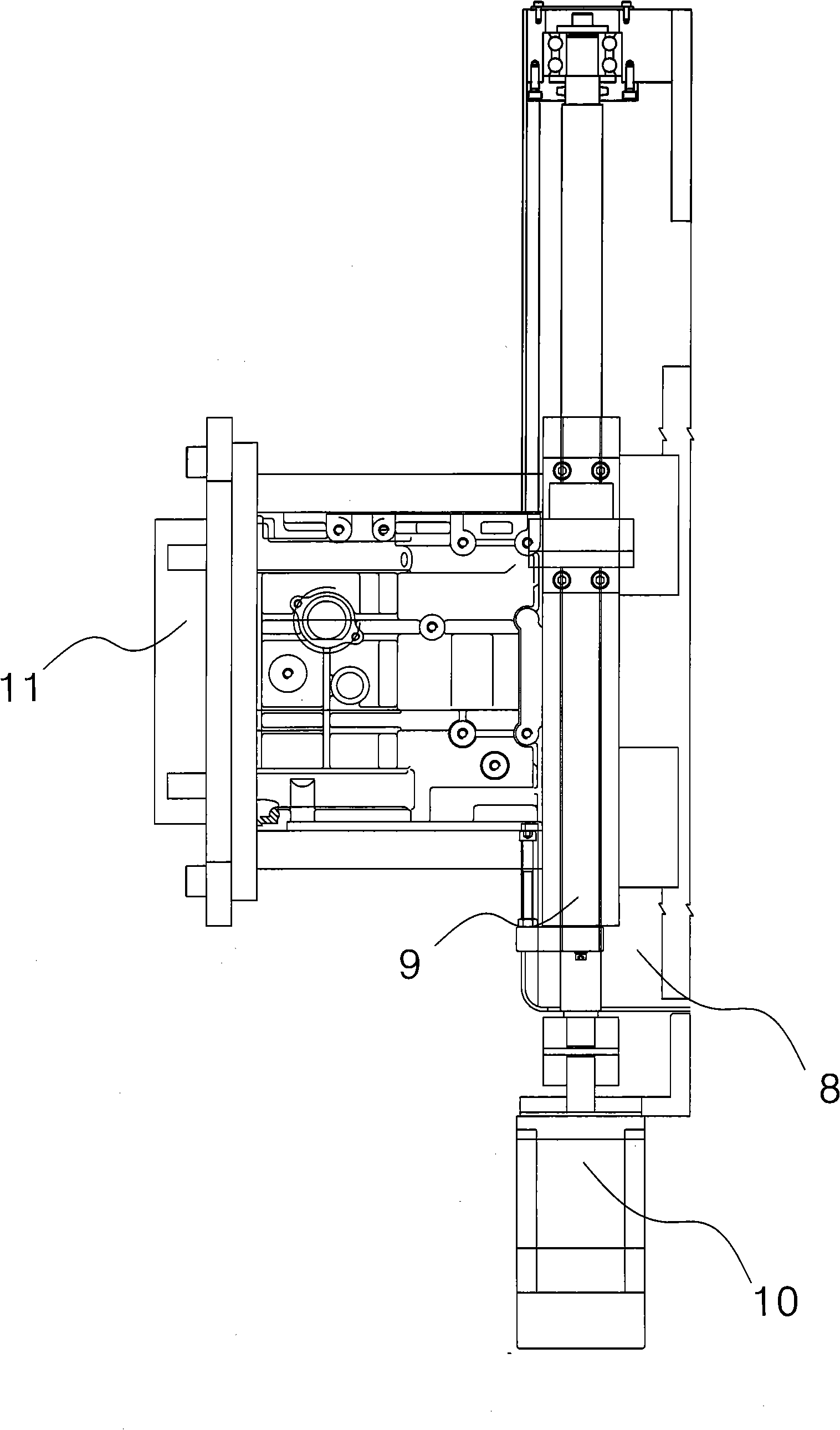

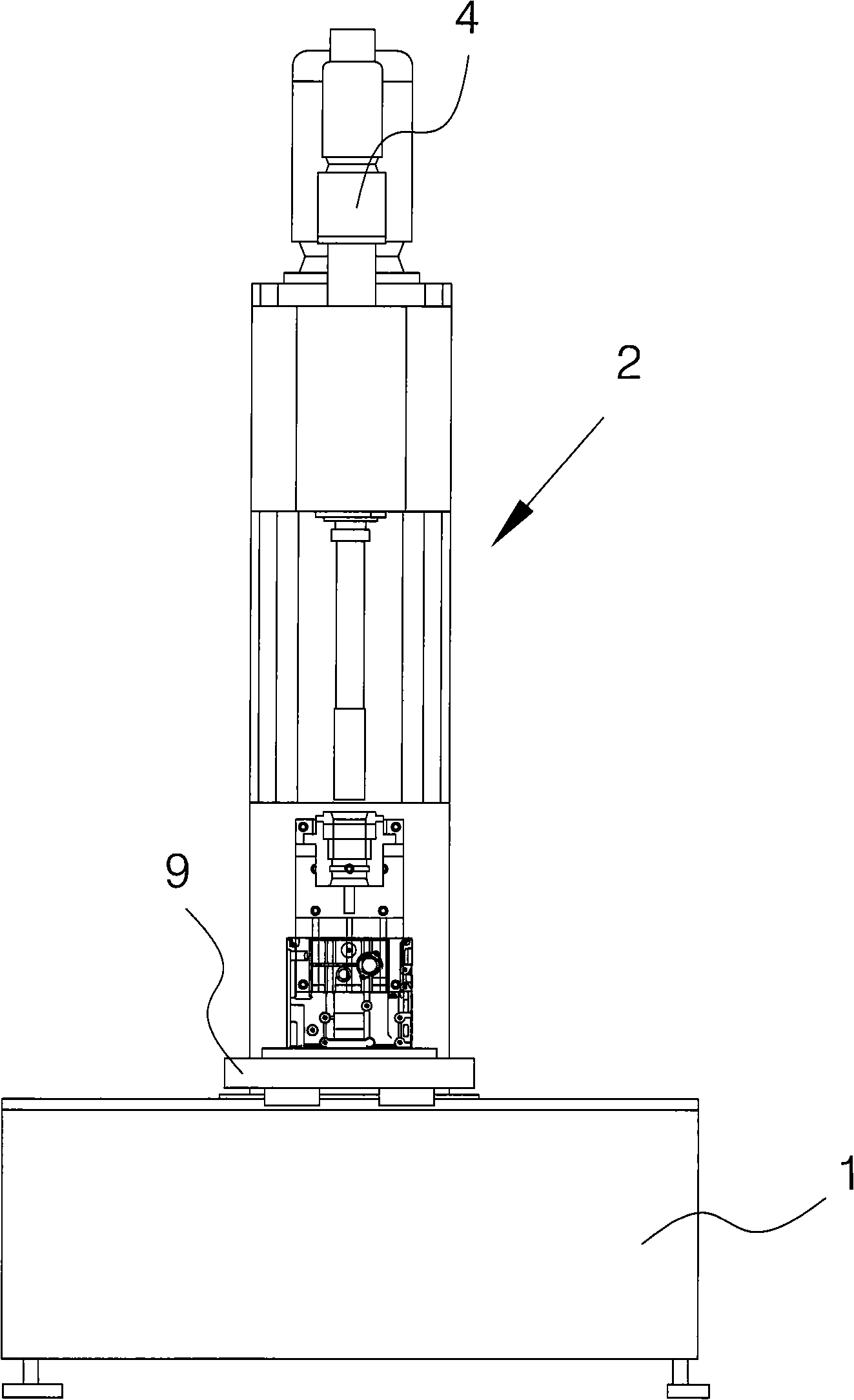

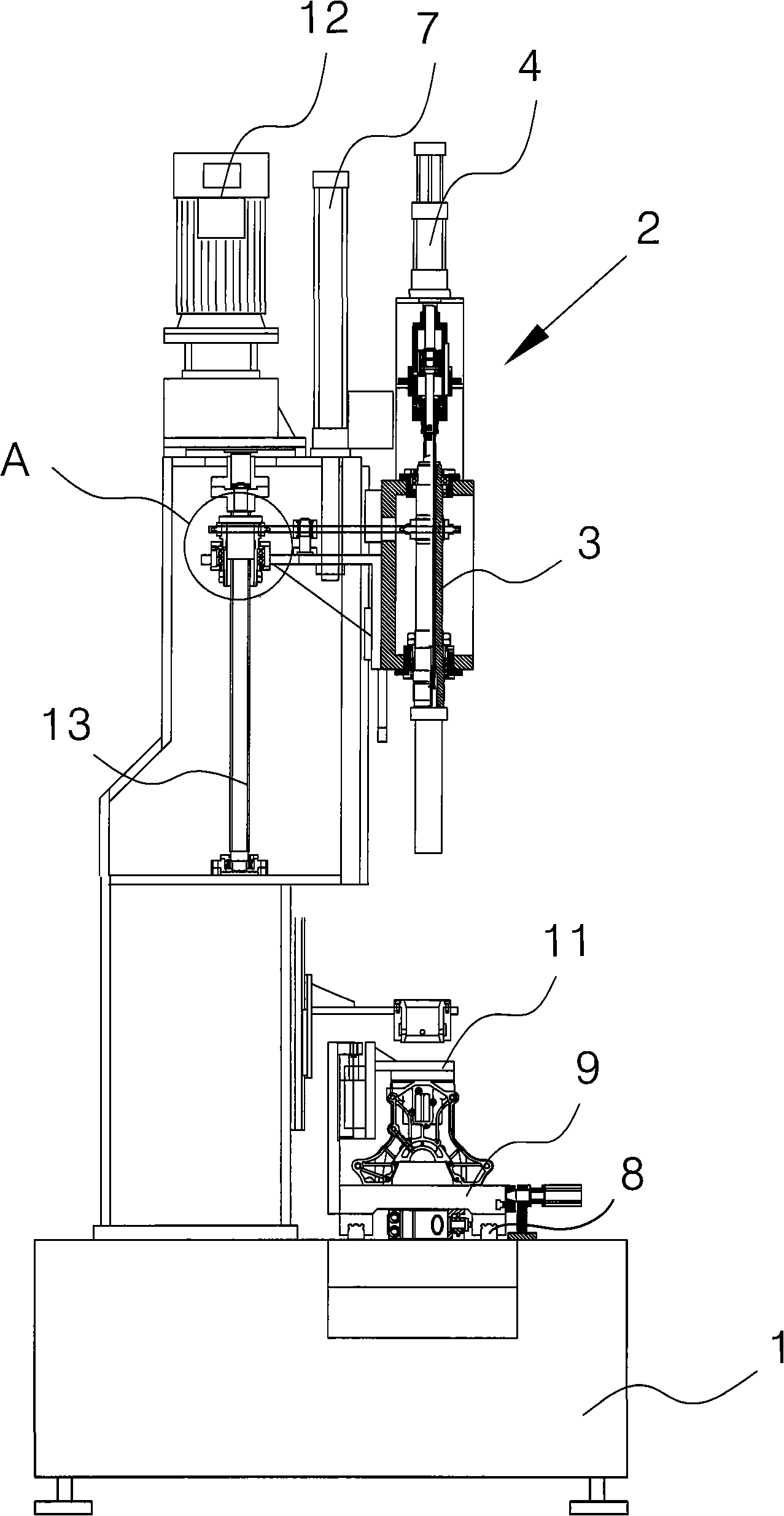

[0016] as attached figure 1 And attached figure 2 A honing machine is shown, which can perform rough honing and fine honing on a workpiece, and it includes a worktable 1, a honing head 2, and a rotary drive mechanism for driving the honing head 2 to rotate. as attached Figure 4 As shown, the honing head 2 includes a main shaft 3, a group of rough honing sand bars and a group of fine honing sand bars arranged on the main shaft 3 (in an embodiment, the rough and fine honing sand bars are along the circumferential surface of the sand bar seat set, and the coarse and fine honing strips are arranged at intervals, when the rough honing strips stretch out radially, the rough honing strips work; when the fine honing strips stretch out radially, fine honing sanding strips for work). The main shaft 3 is provided with a first push cone 5 and a second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com