Fly ash-desulfuration gypsum- concrete self-expandable anti-crack dry powder mortar and method of preparing the same

A technology for desulfurized gypsum and dry powder mortar, applied in the field of building materials, can solve problems such as application limitation, limited strength, and no disclosure, and achieve the effects of improving workability of mortar, reducing dry shrinkage rate, and reducing shrinkage rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

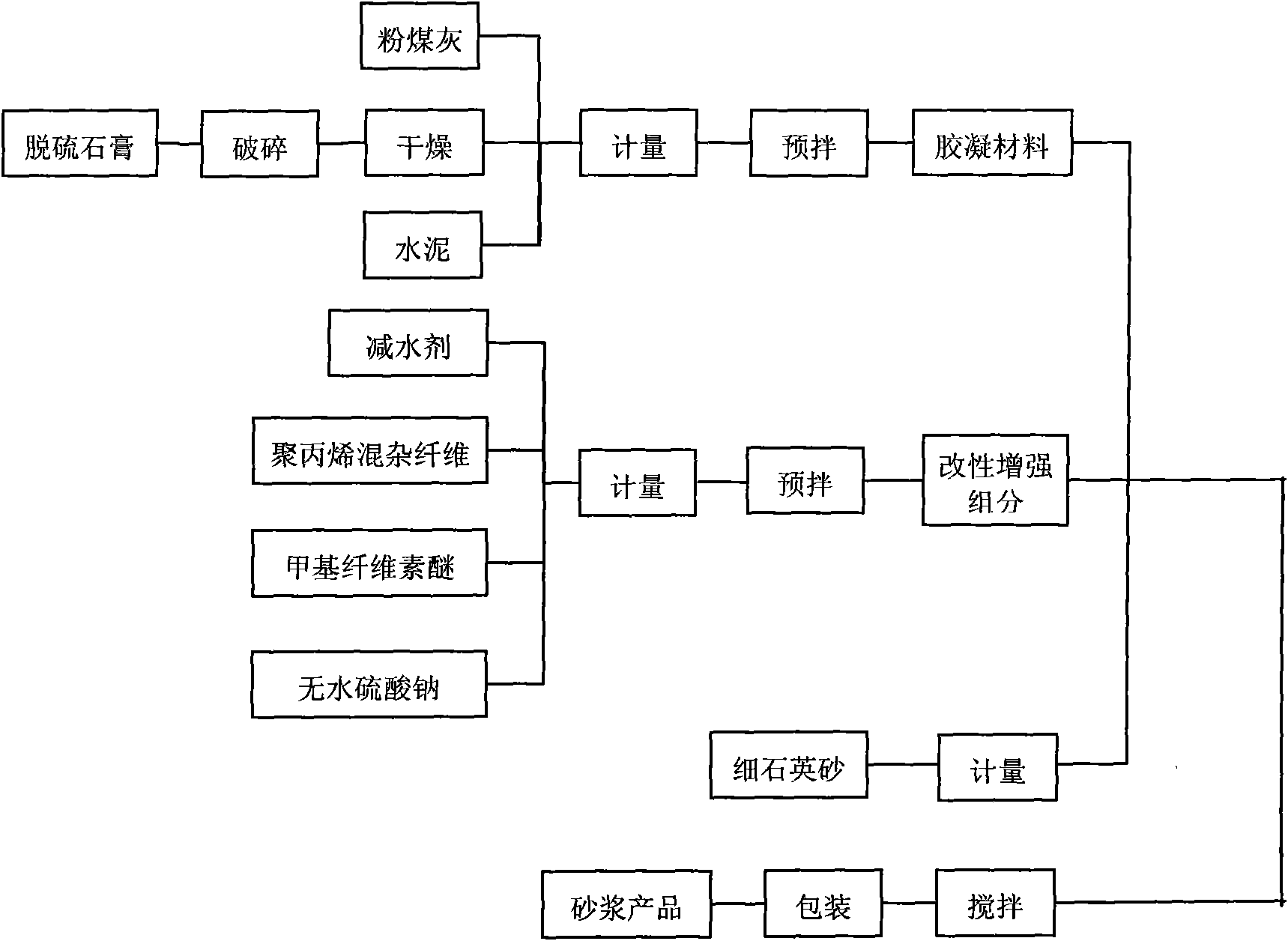

Method used

Image

Examples

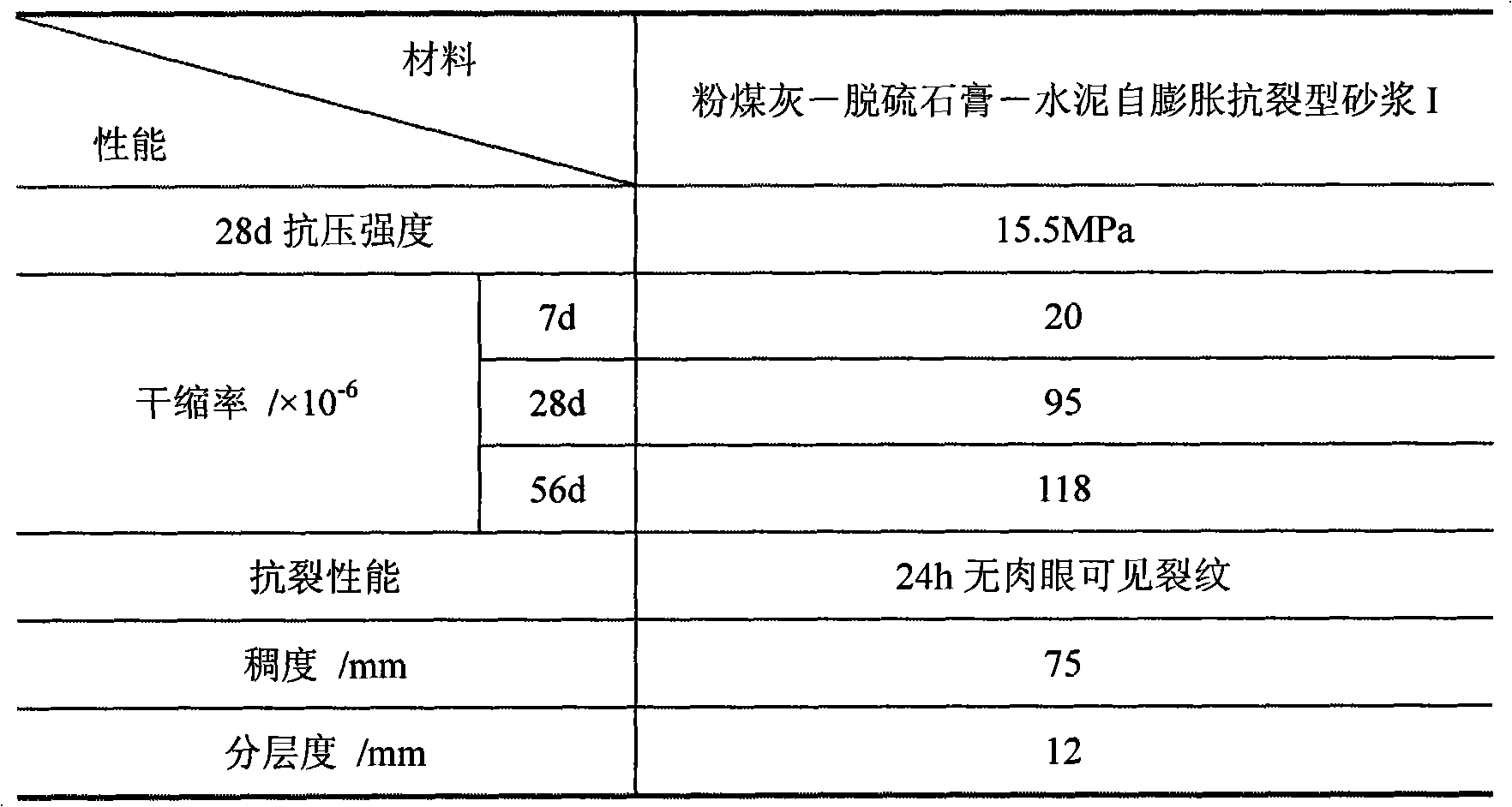

Embodiment 1

[0028] Fly ash-desulfurized gypsum-cement self-expanding anti-cracking dry powder mortar I, select materials according to the following mass ratios:

[0029] Cementitious material:

[0030] ① Power plant desulfurization gypsum: 25%;

[0031] ② Power plant dry discharge class I fly ash: 60%, Blaine specific surface area 420m 2 / kg;

[0032] ③ 42.5 Ordinary Portland cement: 15%.

[0033] Modified Enhanced Components:

[0034] ①Water-reducing agent: naphthalene-based high-efficiency water-reducing agent, mixed at 1.0% of the mass of the gelling material;

[0035] ②Methyl cellulose ether: mixed at 0.1% of the mass of the gelling material;

[0036] ③ Polypropylene mixed fiber: mixed at 0.4% of the mass of the cementitious material;

[0037] ④ Anhydrous sodium sulfate: mixed at 1.0% of the mass of the gelling material.

[0038] Skeleton fine particle material: fine quartz sand particles, mixed with 3 times the mass of cementitious material (1:3 mortar).

[0039] Preparation of...

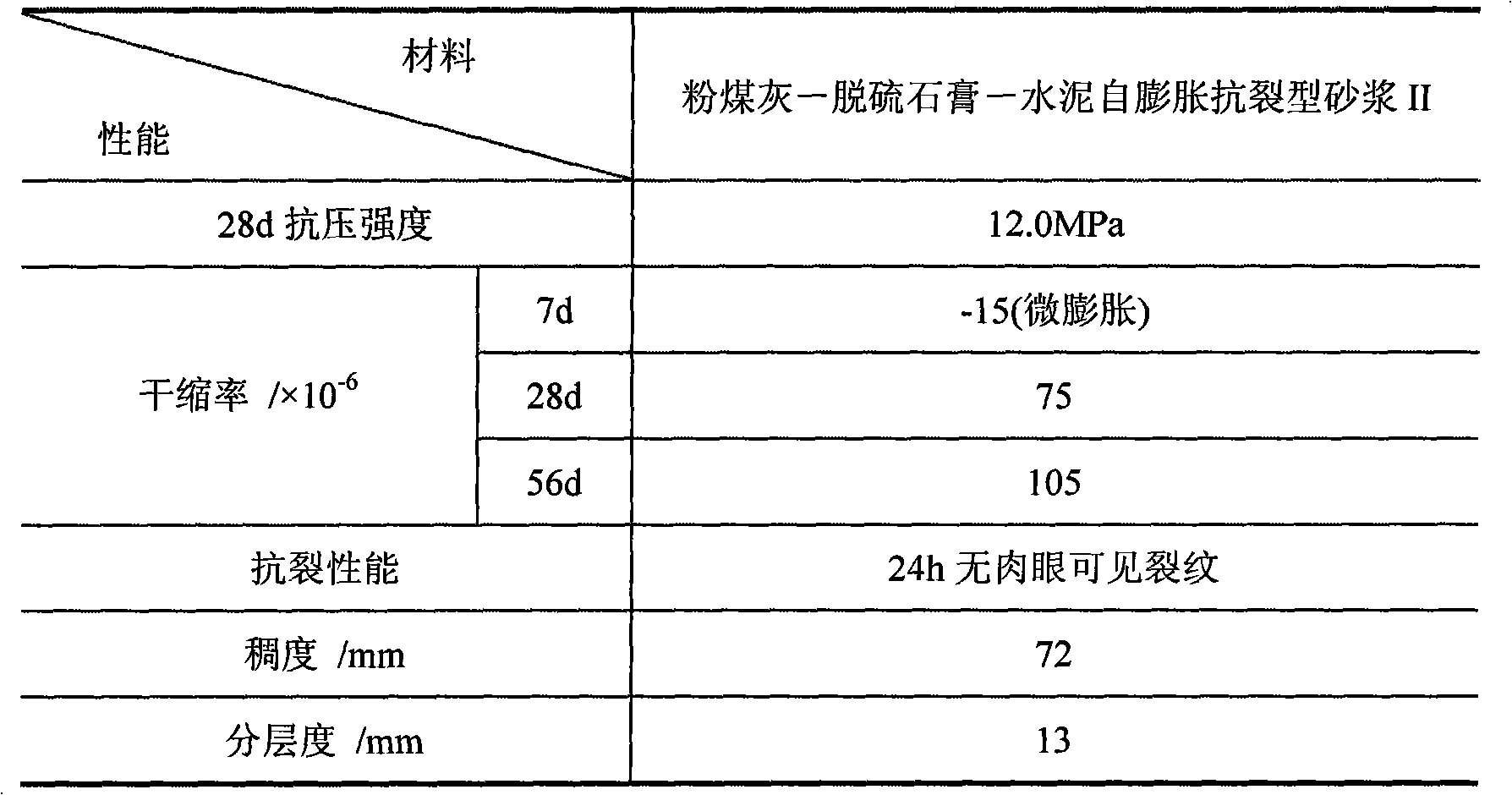

Embodiment 2

[0050] Fly ash-desulfurized gypsum-cement self-expanding anti-cracking dry powder mortar II, select materials according to the following mass ratio:

[0051] Cementitious material:

[0052] ① Power plant desulfurization gypsum: 20%;

[0053] ②Power plant dry discharge class II fly ash: 60%, Blaine specific surface area 300m 2 / kg;

[0054] ③42.5 Ordinary Portland cement: 20%.

[0055] Modified Enhanced Components:

[0056] ①Water-reducer: naphthalene-based high-efficiency water-reducer, mixed in at 1.5% of the mass of the gelling material;

[0057] ②Methyl cellulose ether: mixed at 0.1% of the mass of the gelling material;

[0058] ③ Polypropylene mixed fiber: mixed at 0.5% of the mass of the cementitious material;

[0059] ④ Anhydrous sodium sulfate: mixed at 1.5% of the mass of the gelling material.

[0060] Skeleton fine particle material: fine quartz sand particles, mixed with 3 times the mass of cementitious material (1:3 mortar).

[0061] Preparation of fly ash-d...

Embodiment 3

[0071] Fly ash-desulfurized gypsum-cement self-expanding anti-cracking dry powder mortar III, select materials according to the following mass ratio:

[0072] Cementitious material:

[0073] ① Power plant desulfurization gypsum: 30%;

[0074] ②Plant dry discharge class I fly ash: 55%, Blaine specific surface area 420m 2 / kg;

[0075] ③ 42.5 Ordinary Portland cement: 15%.

[0076] Modified Enhanced Components:

[0077] ①Water-reducing agent: naphthalene-based high-efficiency water-reducing agent, mixed at 1.0% of the mass of the gelling material;

[0078] ②Methyl cellulose ether: mixed at 0.1% of the mass of the gelling material;

[0079] ③ Polypropylene mixed fiber: mixed at 0.4% of the mass of the cementitious material;

[0080] ④ Anhydrous sodium sulfate: mixed at 1.0% of the mass of the gelling material.

[0081] Skeleton fine particle material: fine quartz sand particles, mixed in at 2.5 times the mass of the cementitious material (1:2.5 mortar).

[0082] Preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Blaine specific surface area | aaaaa | aaaaa |

| Blaine specific surface area | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com