Environment-friendly marine antifouling coating for finishing boat

A marine antifouling and coating technology, applied in antifouling/underwater coatings, rosin coatings, coatings, etc., can solve problems such as marine ecological environment hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below by two specific examples:

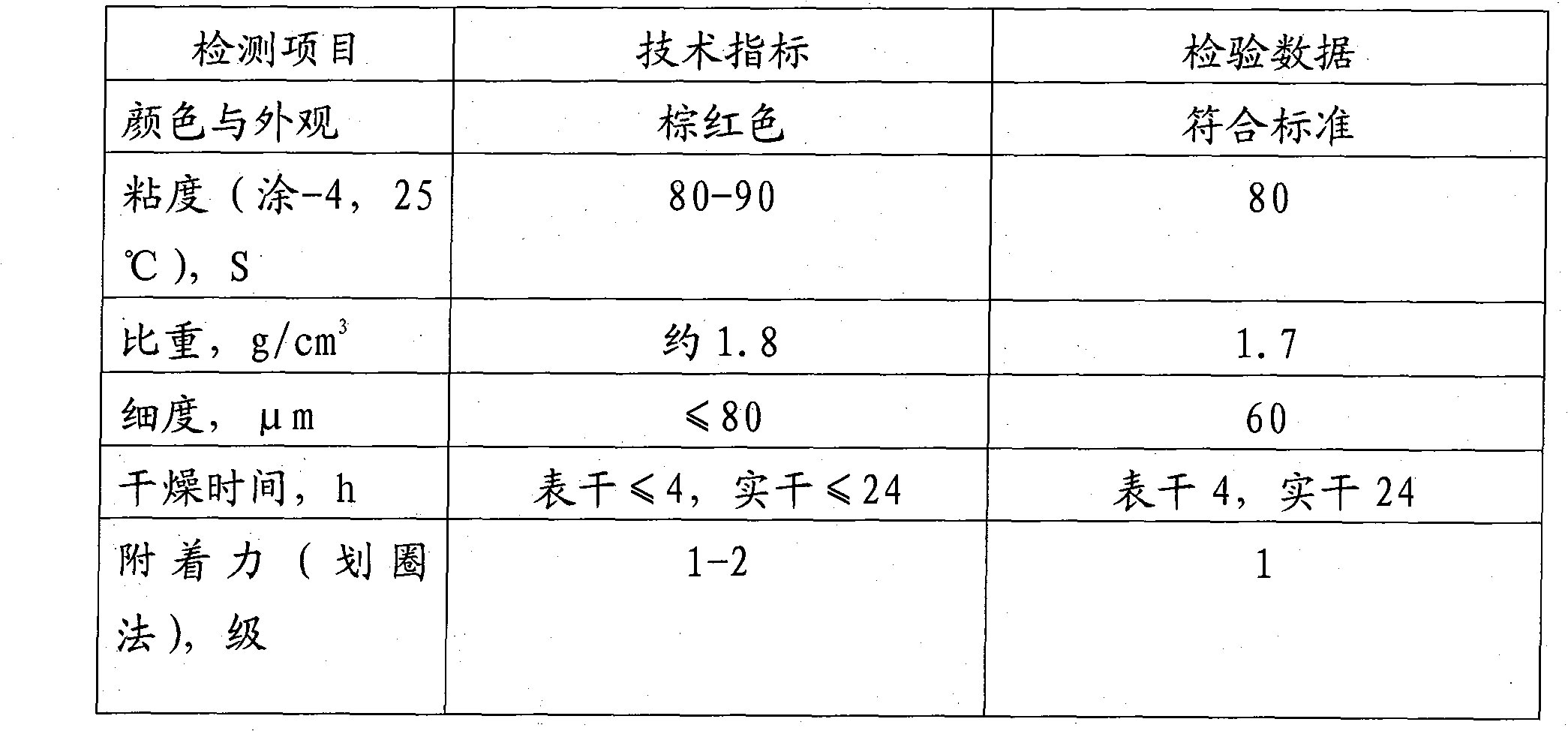

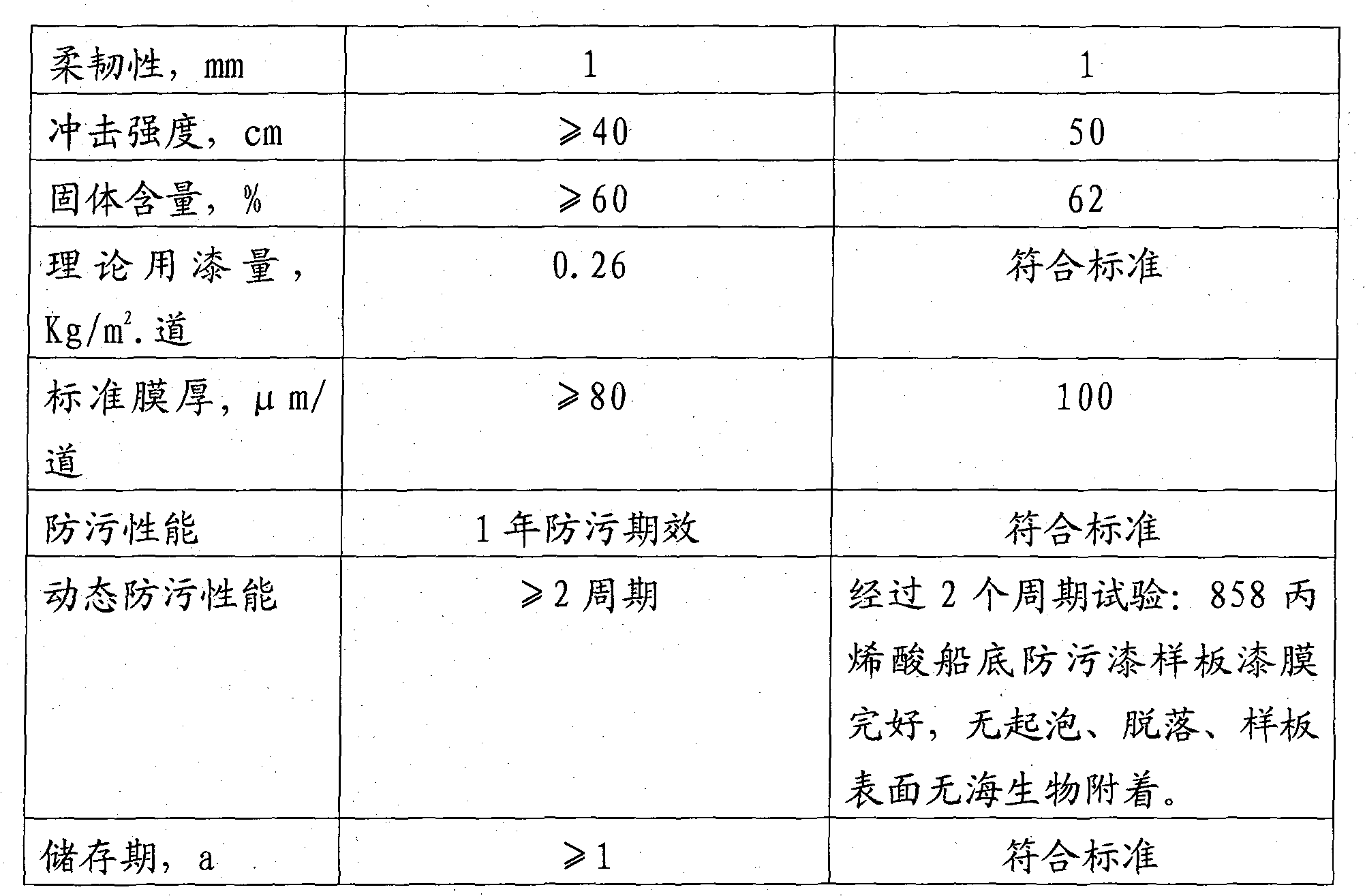

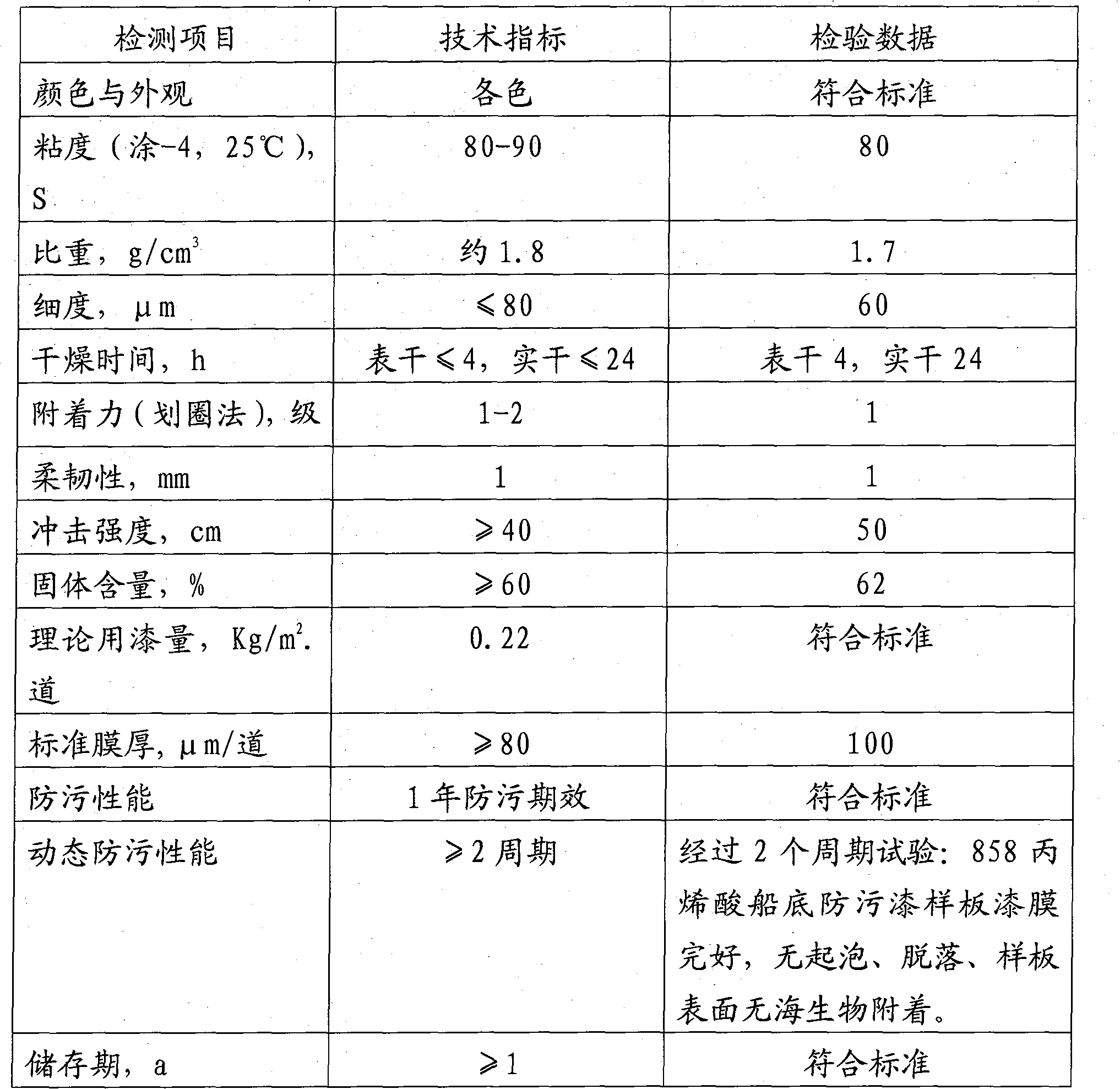

[0022] Embodiment one of the present invention is " 858 acrylic acid ship bottom antifouling paints ", and the formula by weight is:

[0023] (1) Acrylic resin: 20 parts by weight

[0024] (2) Rosin: 15 parts by weight

[0025] (3) Composite organic antifouling agent: 10 parts by weight of cuprous thiocyanate (CuSCN), 5 parts by weight of copper pyrithione, and 5 parts by weight of chlorothalonil

[0026] (4) Pigment: 3 parts by weight of talcum powder, 10 parts by weight of zinc oxide, 3 parts by weight of iron red

[0027] (5) The mixed solvent is: 20 parts by weight of xylene, 5 parts by weight of butyl acetate

[0028] (6) Anti-settling agent: 2 grams of organic bentonite

[0029] The preparation method is as follows:

[0030] First dissolve all the acrylic acid and rosin resin in the mixed solvent, fully dissolve, then add compound organic antifouling agent, pigment and filler, anti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com