Airlift type photobioreactor

A photobioreactor and airlift technology, which is applied in the direction of photobioreactor, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve problems such as difficulty in meeting requirements, and achieve operational Convenience, good liquid mixing, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

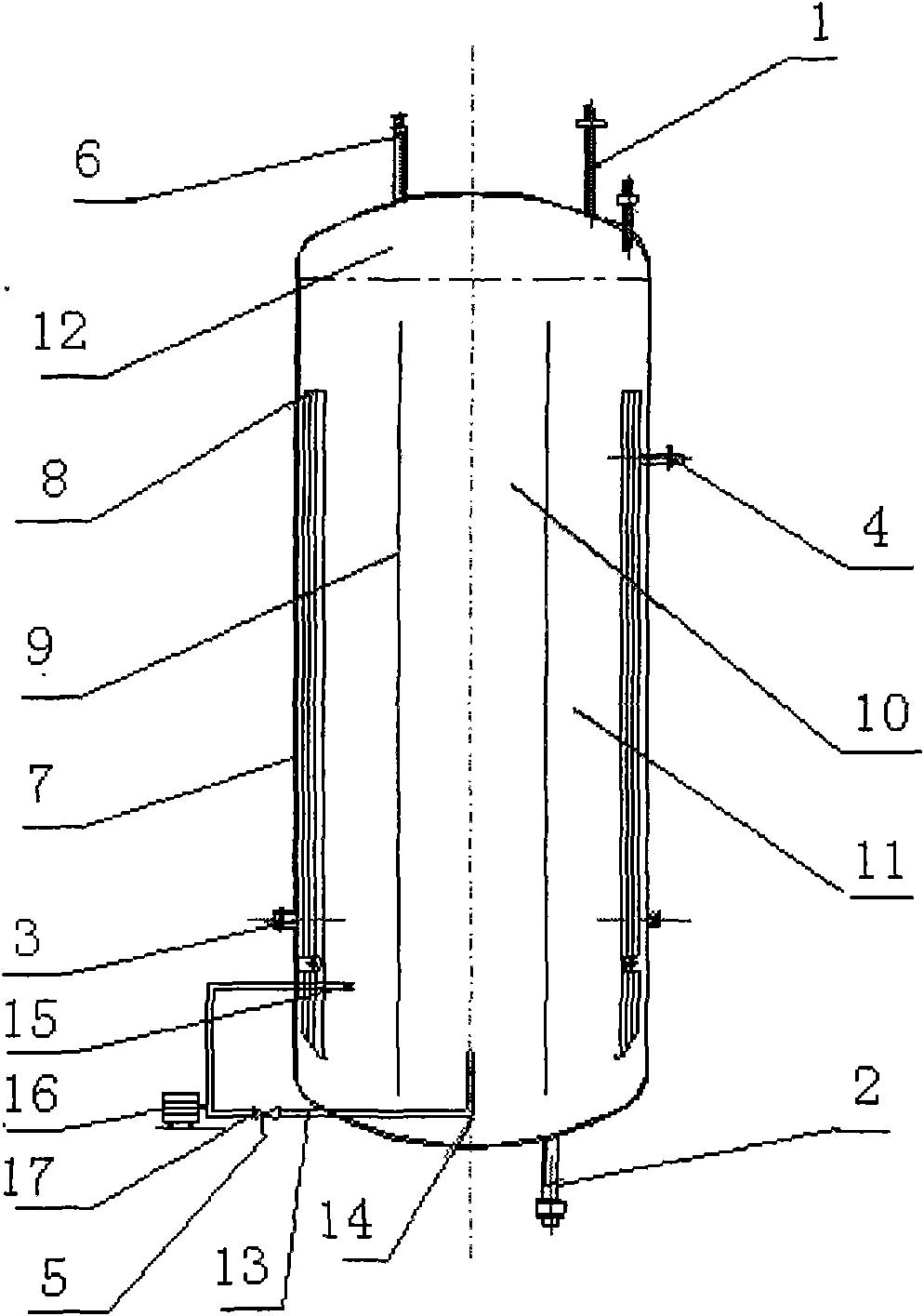

[0017] Below in conjunction with accompanying drawing, the present invention will be further explained:

[0018] refer to figure 1 , The upper end of the glass tank 7 of the airlift photobioreactor is provided with an exhaust port 6, a medium inlet 1, and a culture medium outlet 2 is provided at the lower end. The inside of the glass tank body 7 is annularly provided with multiple groups of heat exchange tubes 8 that are respectively connected to the cooling water inlet 3 and the cooling water outlet 4 on the glass tank body 7. The heat exchange tubes 8 can be serpentine or other shapes; The center line of the tank body 7 is provided with an ascending conduit 9, and the ascending conduit 9 can be fixed on the glass tank body 7 by a bracket. The inside thereof is an ascending zone 10, and the outside is a descending zone 11. The gas distributor 14 connected to the outlet end of the pipeline 13, the inlet end of the air inlet pipeline 13 is provided with a Venturi tube 17, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com