Method for generating hydrogen in microorganism electrolysis cell with protein

A microbial electrolysis cell and protein technology, which is applied in the field of hydrogen production, can solve the problem that the fermentation method cannot use protein to produce hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

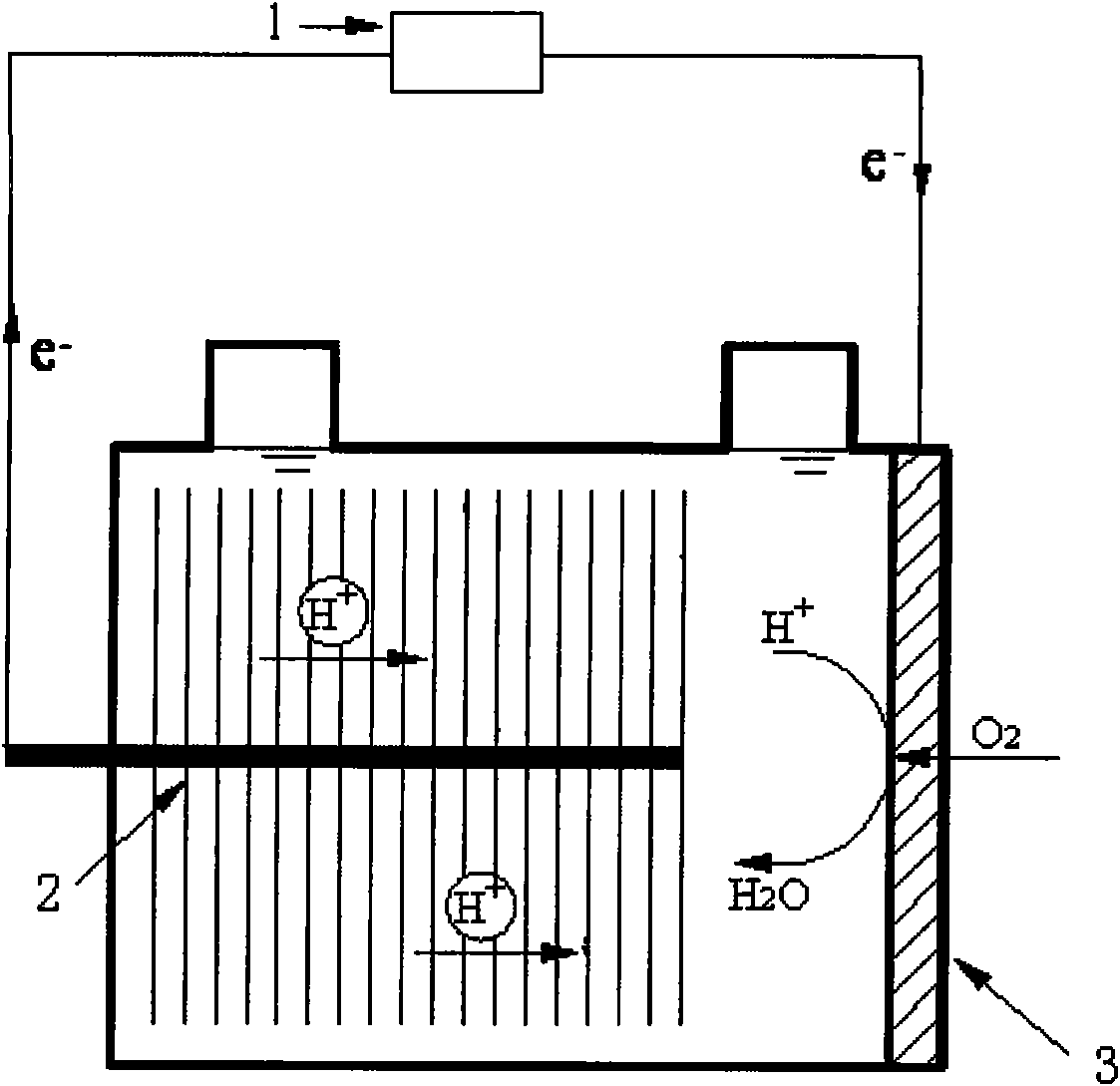

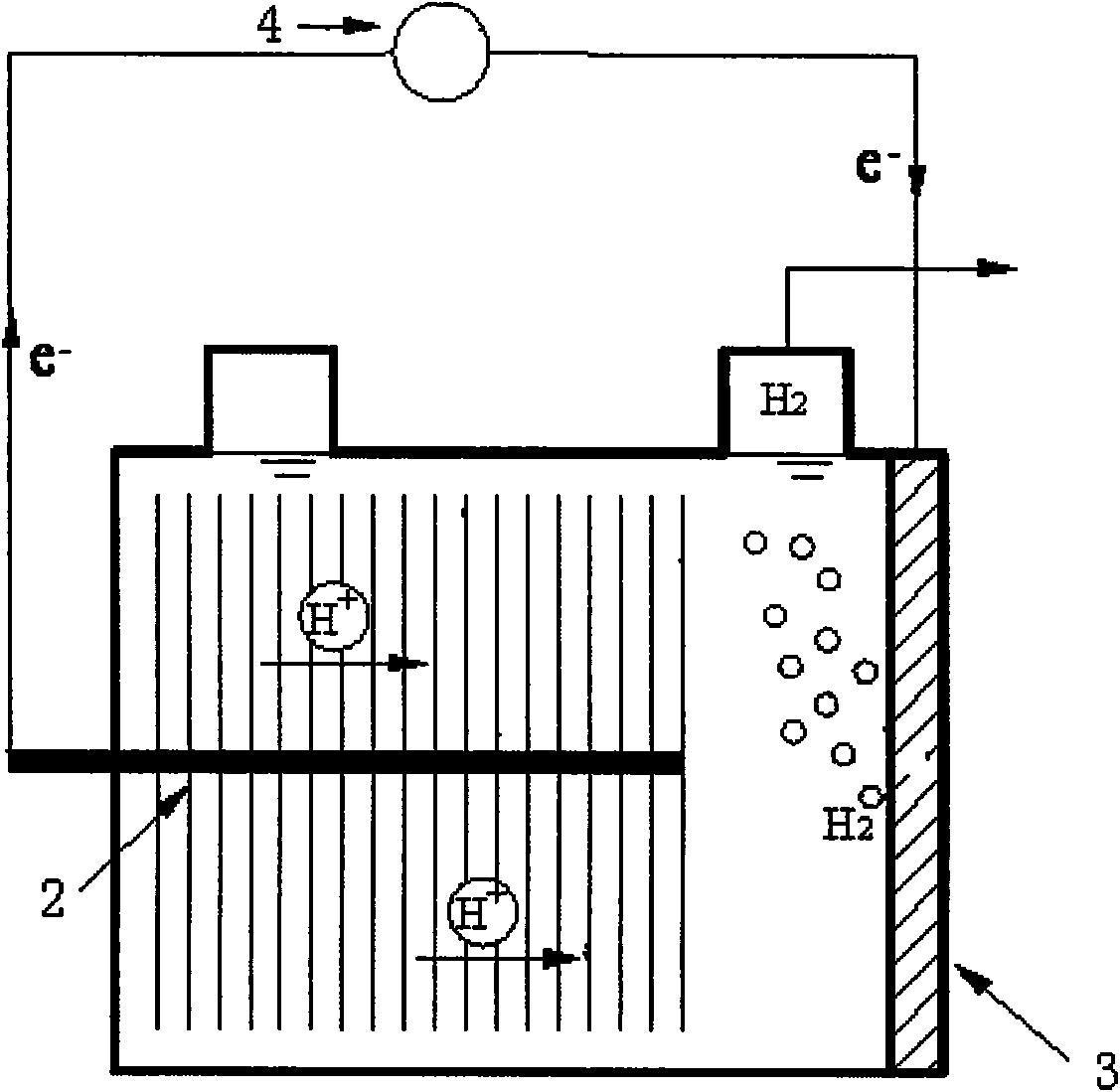

[0012] Specific implementation mode one: combine figure 1 and figure 2 Illustrate that this embodiment utilizes the method for protein to produce hydrogen in the microbial electrolysis cell to realize according to the following steps:

[0013] 1. Start the reactor in electricity production mode: a resistor 1 is set in the closed circuit using the electrolytic cell as the power supply, and the domestic sewage and the nutrient solution A are uniformly mixed according to the volume ratio of 1:1 to obtain the mixed solution C, and then the mixed solution The liquid C is passed into the electrolytic cell, and the new mixed liquid C is replaced under the condition that the voltage across the resistance 1 of the closed loop is lower than 25mV, and the mixed liquid C is continuously replaced until the voltage across the resistance 1 is greater than 500mV;

[0014] 2. Dissolve the protein in the nutrient solution B to obtain the mixed solution D, then replace the mixed solution C in ...

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that the domestic sewage in step 1 is obtained from the primary sedimentation tank of the urban sewage treatment plant. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0021] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the cathode Pt load in step one is 0.5 mg / cm 2 . Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com