Driving device for manufacturing underground continuous wall and jointing method

A technology for underground diaphragm walls and driving devices, applied in sheet pile walls, underwater structures, water conservancy projects, etc., can solve problems such as low shear resistance, high cost, and poor integrity, and achieve strong digital selectivity and applicable Wide-ranging, quality-assured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

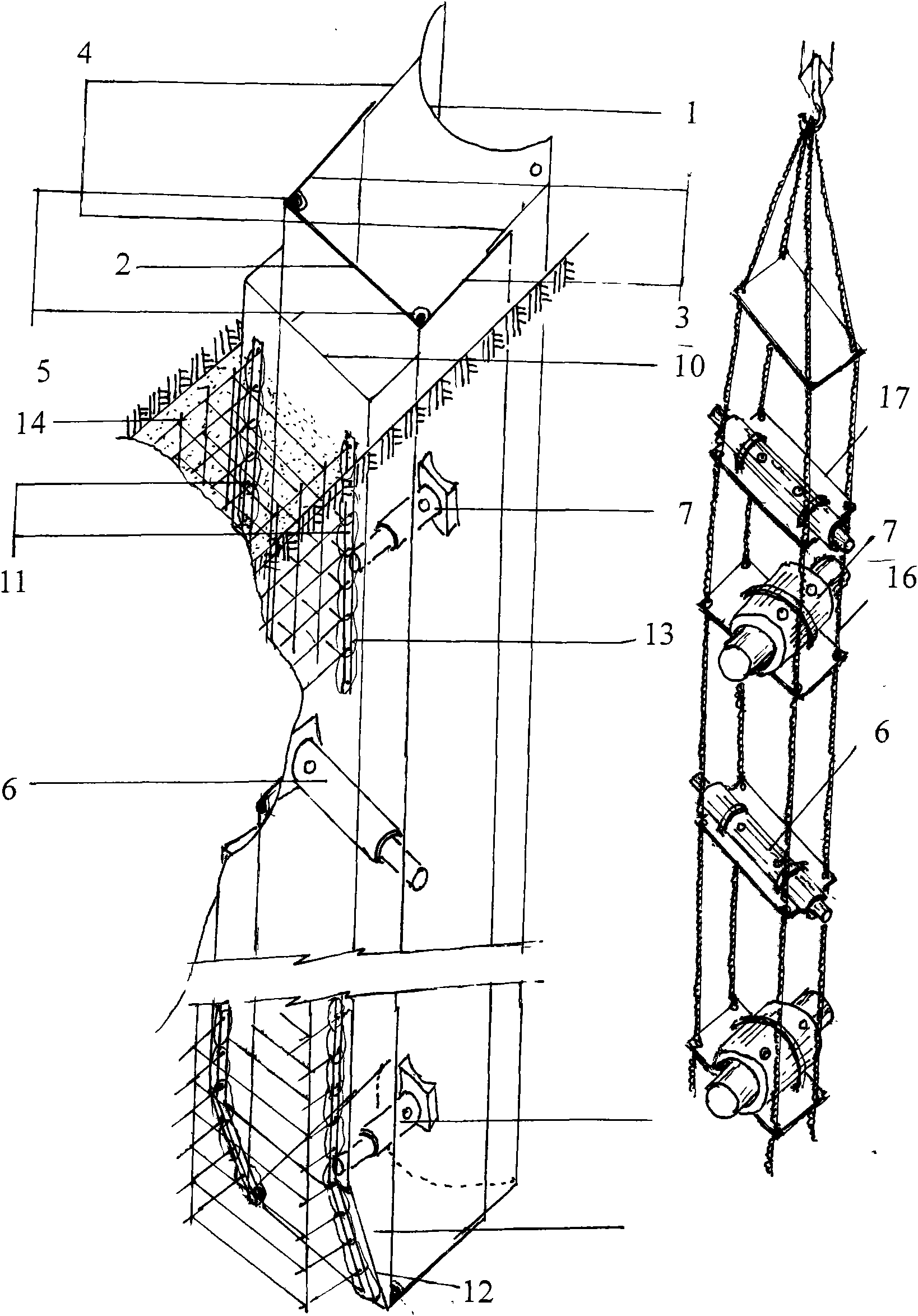

[0031] Such as figure 1 The hydraulic drive unit is shown in the figure

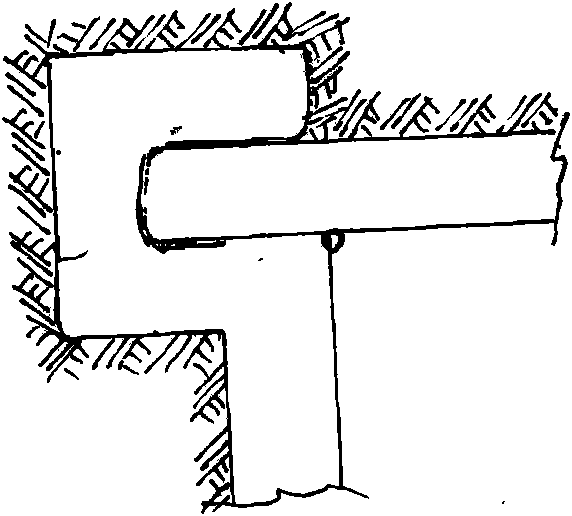

[0032] (A) The supporting plate 3 and the blocking plate 2 are formed into a [shaped structure by the shaft 5.

[0033] (B) The support plate 3 is vertically supported on the groove wall around the axis 5 after the hydraulic cylinder 6 works

[0034] (C) The hydraulic cylinder 7 supports the blocking plate 2 and the meniscus device to force the rotary drill to rotate

[0035] (D) The groove wall is unstable and the meniscus device pulls the sliding plate 4 enclosure

[0036] (E) After the hydraulic cylinder 6 is retracted, the hydraulic cylinder 7 is retracted to force the [shaped structure to move forward.

[0037] (F) Hydraulic cylinders 6 and 7 can also be hoisted into the [shaped structure by means of rope 16, bracket 17, effective digits in series, respectively, depending on the working conditions.

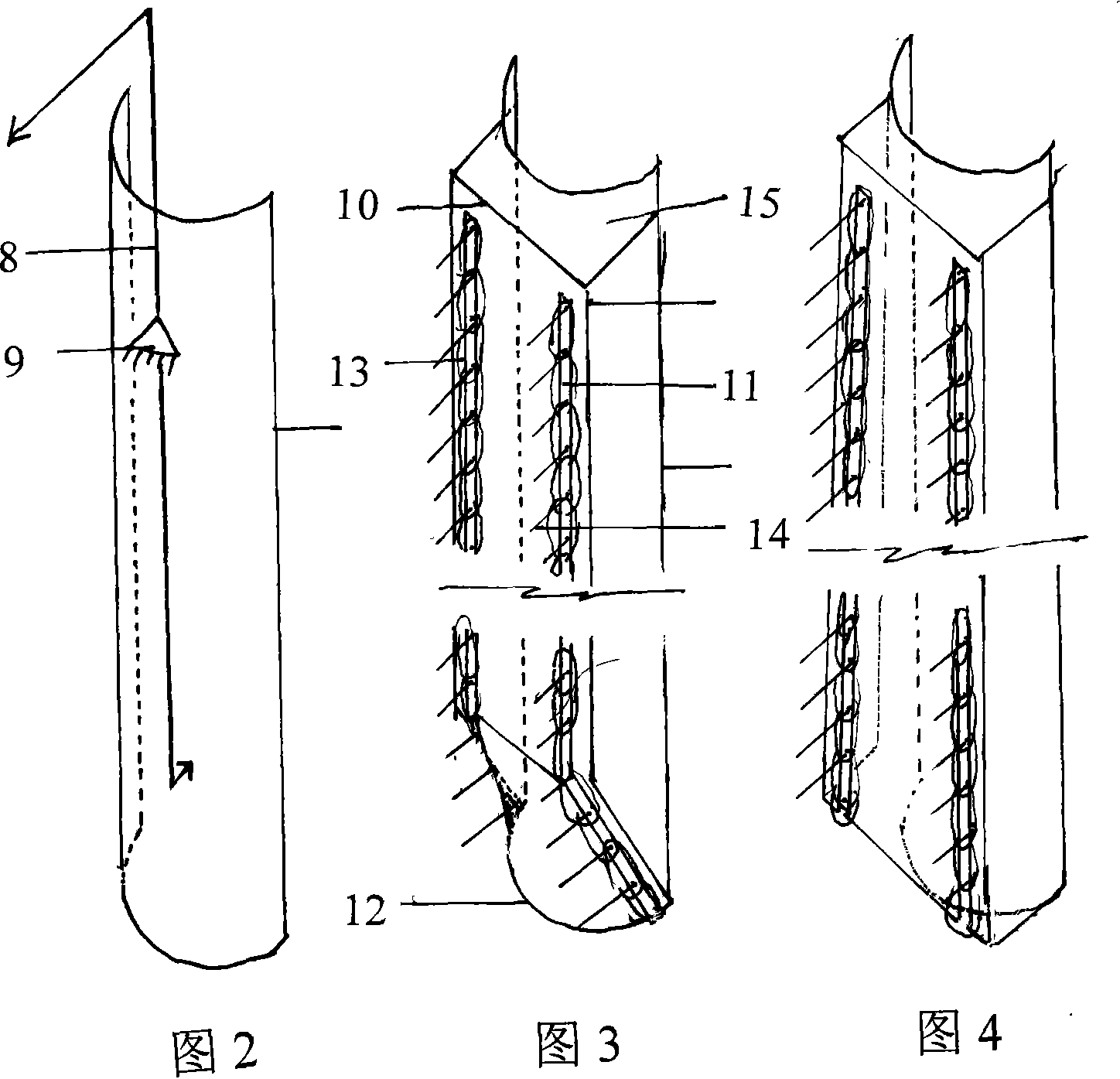

[0038] Such as figure 2 The lever support is shown in the diagram

[0039] (A) The fulcrum 9 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap