Composite magnet

A composite magnet and magnet technology, used in the manufacture of magnets, magnetic objects, inductors/transformers/magnets, etc., can solve the problems of weakening, high temperature resistance, weak magnetic field strength, etc., to achieve good magnetization or polarization effect, large remanence , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation

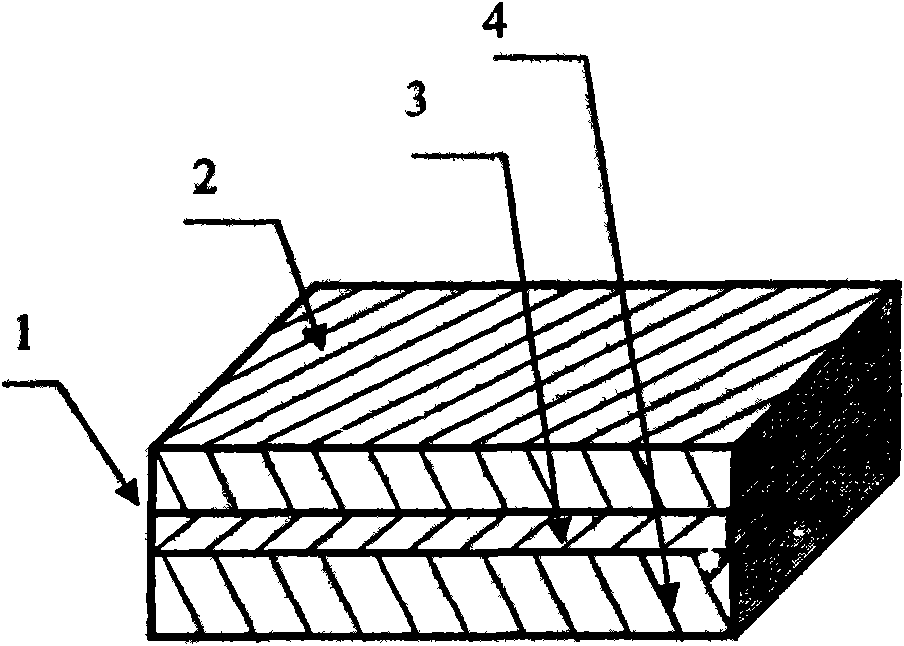

[0013] exist figure 1 Among them, the composite magnet (1) is composed of NdFeB magnet (2) and SmCo magnet or AlNiCo magnet or FeCrCo magnet or ferrite magnet and other high temperature resistant magnets (4) one of the magnets is self- The composite magnet (1) with a heat insulating layer (3) can be formed by adding a heat insulating material between the NdFeB magnet (2) and other magnets if necessary. Certainly also can utilize NdFeB magnet (2) and plastic soft magnet or rubber soft magnet self-priming together to form composite magnet (1), also can all self-priming plastics on both sides of NdFeB magnet (2) when needed Soft magnets or rubber soft magnets form a composite magnet (1) whose two sides are soft magnets and the middle of which is hard magnets.

[0014] The shape of the composite magnet (1) can be various shapes such as square, rectangle, circle, ellipse, tile type, and the size of the composite magnet is determined according to n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com