Connector, transformation set and backlight module with voltage conversion function

A technology of transformer module and voltage conversion, which is applied to the parts, connections, electric light sources, etc. of the connecting device, can solve the problems of electric shock danger for assemblers, the space occupied by printed circuit boards, and the inability to meet the trend of thinning liquid crystal displays, etc. Achieve the effect of saving production costs and reducing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

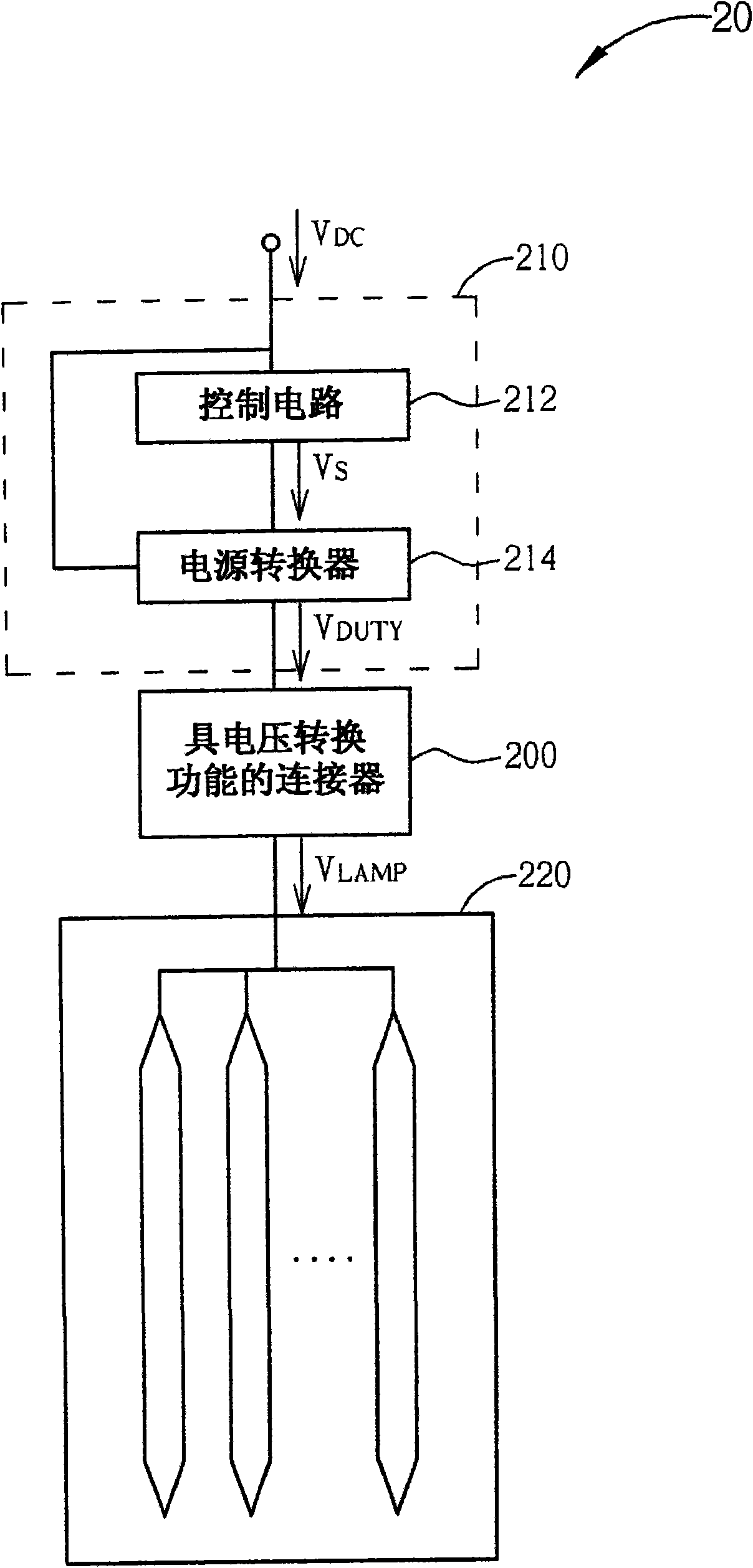

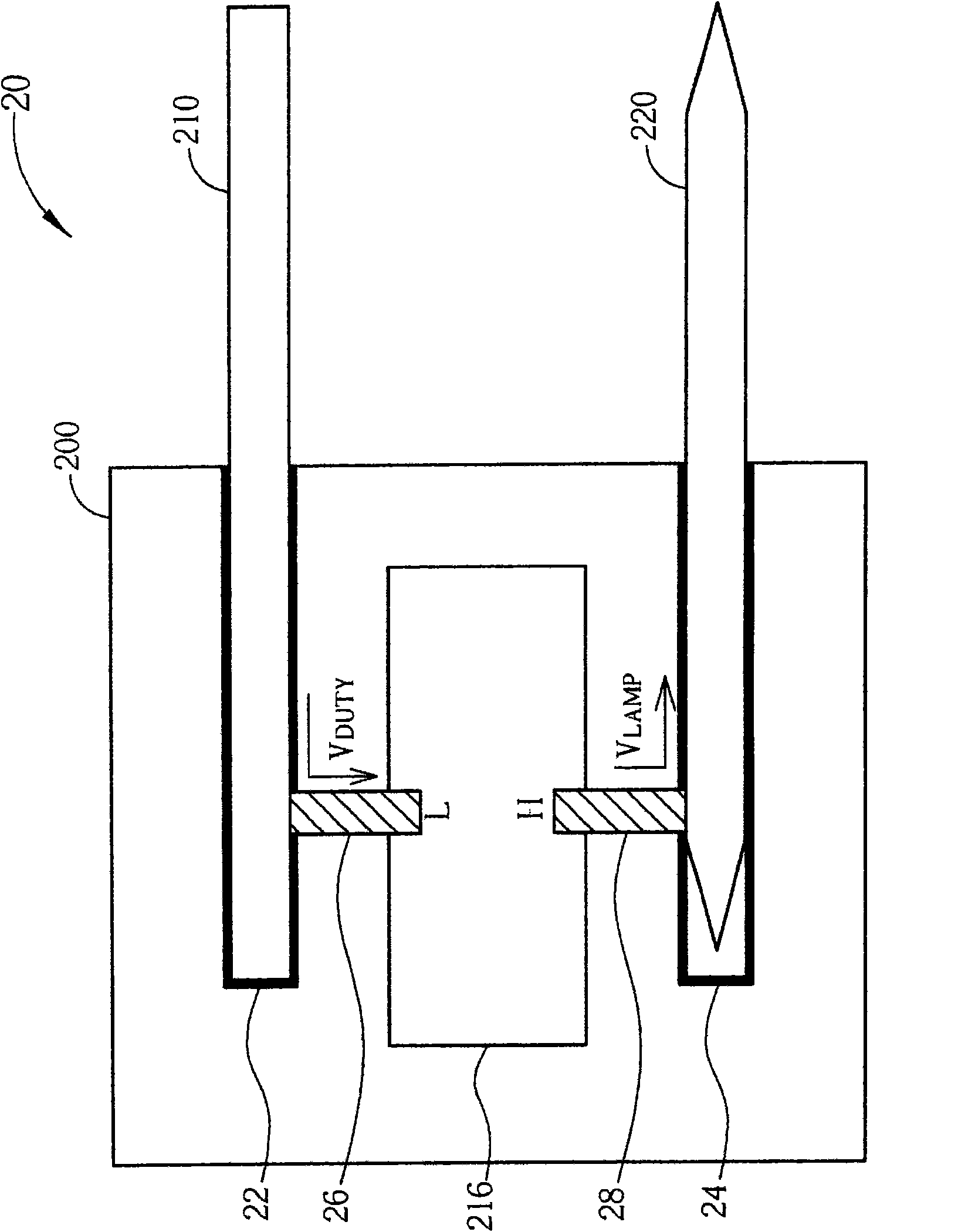

[0032] Please refer to figure 2 , figure 2 It is a functional block diagram of the backlight module 20 in the first embodiment of the present invention. The backlight module 20 includes an inverter 210 , a lamp set 220 , and a connector 200 with a voltage conversion function. The inverter 210 includes a control circuit 212 and a power converter 214. The control circuit 212 can transmit the DC signal V according to the driving circuit of the liquid crystal display. DC to generate a control signal V corresponding to each lamp in the lamp group 220 S , while the power converter 214 can respond to the DC signal V DC Conversion is performed to output a positive and negative symmetrical low voltage variable duty cycle signal V DUTY . The inverter 210 is usually fabricated on a printed circuit board, and can output a variable duty period signal V through multiple signal output terminals. DUTY . The connector 200 with voltage conversion function includes multiple sets of conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com