Method for preparing polycrystalline silicon

A technology of polysilicon and silicon rods, which is applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of undisclosed polysilicon, etc., and achieve the effects of improving deposition uniformity, gentle heating rate, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

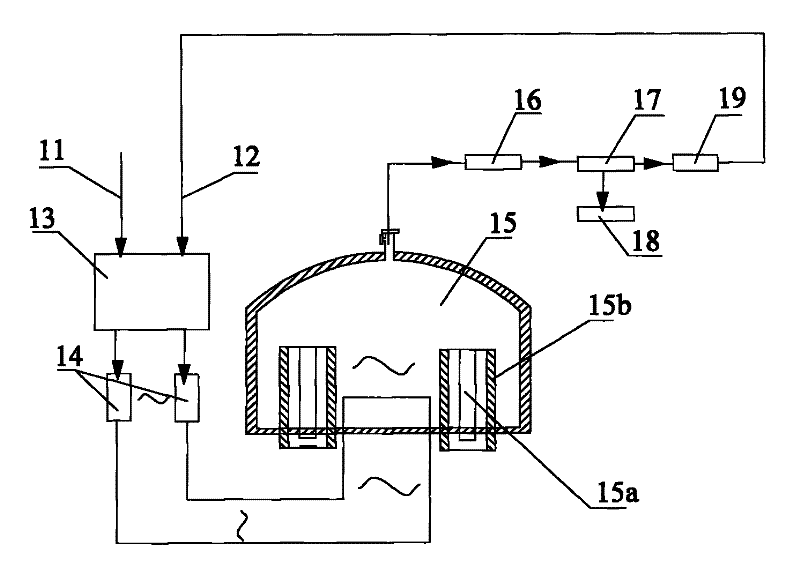

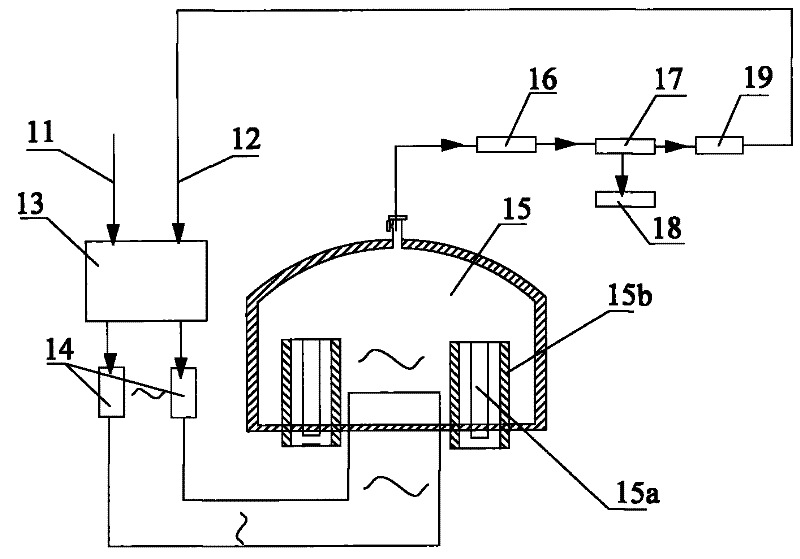

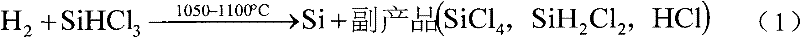

Method used

Image

Examples

Embodiment 1

[0058] Mix hydrogen and monosilane in a static mixer to obtain a first mixed gas, the purity of hydrogen is 99.999%, and the purity of monosilane is 99.999%. Then, the first mixed gas is continuously sent to the twelve-way preheater for preheating, and the preheating temperature is 260°C.

[0059] The preheated first mixed gas is sent into the reactor in twelve ways. The inner diameter of the reactor is 3 meters and the length is 3 meters. The reactor is also provided with a measuring device (not shown) for measuring the size of the silicon rod. Before the first mixed gas is sent into the reactor, the silicon rod is preheated to 260° C. through a heating mantle. Please refer to Table 1 for the silicon rod growth size process table formulated in this embodiment:

[0060] Table 1 Silicon rod growth size process

[0061]

[0062] According to the process table shown in Table 1, the mixing ratio of monosilane and hydrogen is adjusted in the range of 1:0.2~1:3 according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com