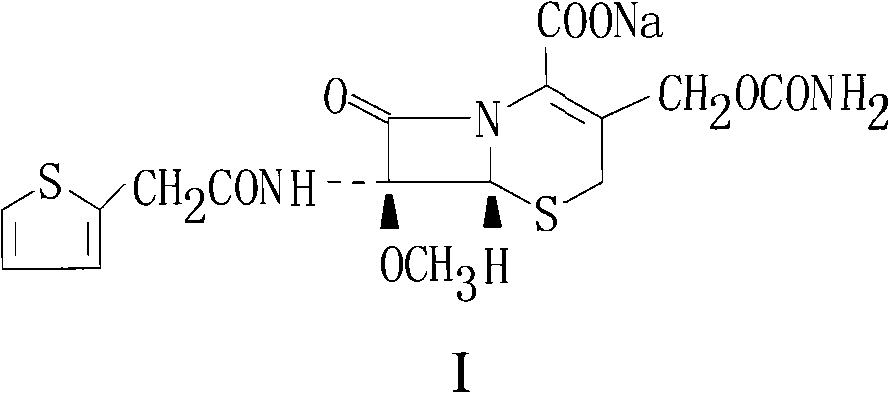

Method for detecting impurities in cefoxitin product

A cefoxitin and detection head technology, applied in the field of detection of impurities in cefoxitin products, can solve the problems of inability to distinguish four impurities, quantitative research, etc., and achieve the effects of reducing adverse reactions, effective quality, and strong specificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

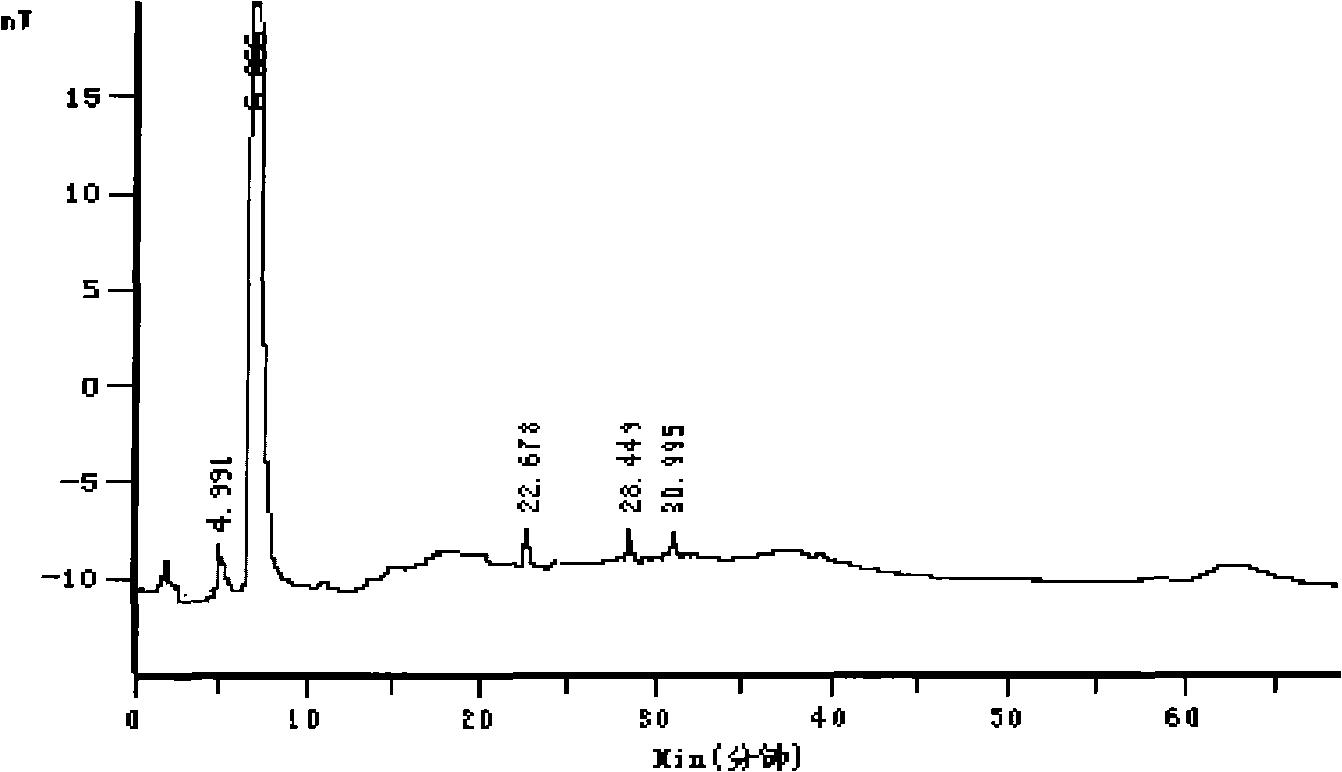

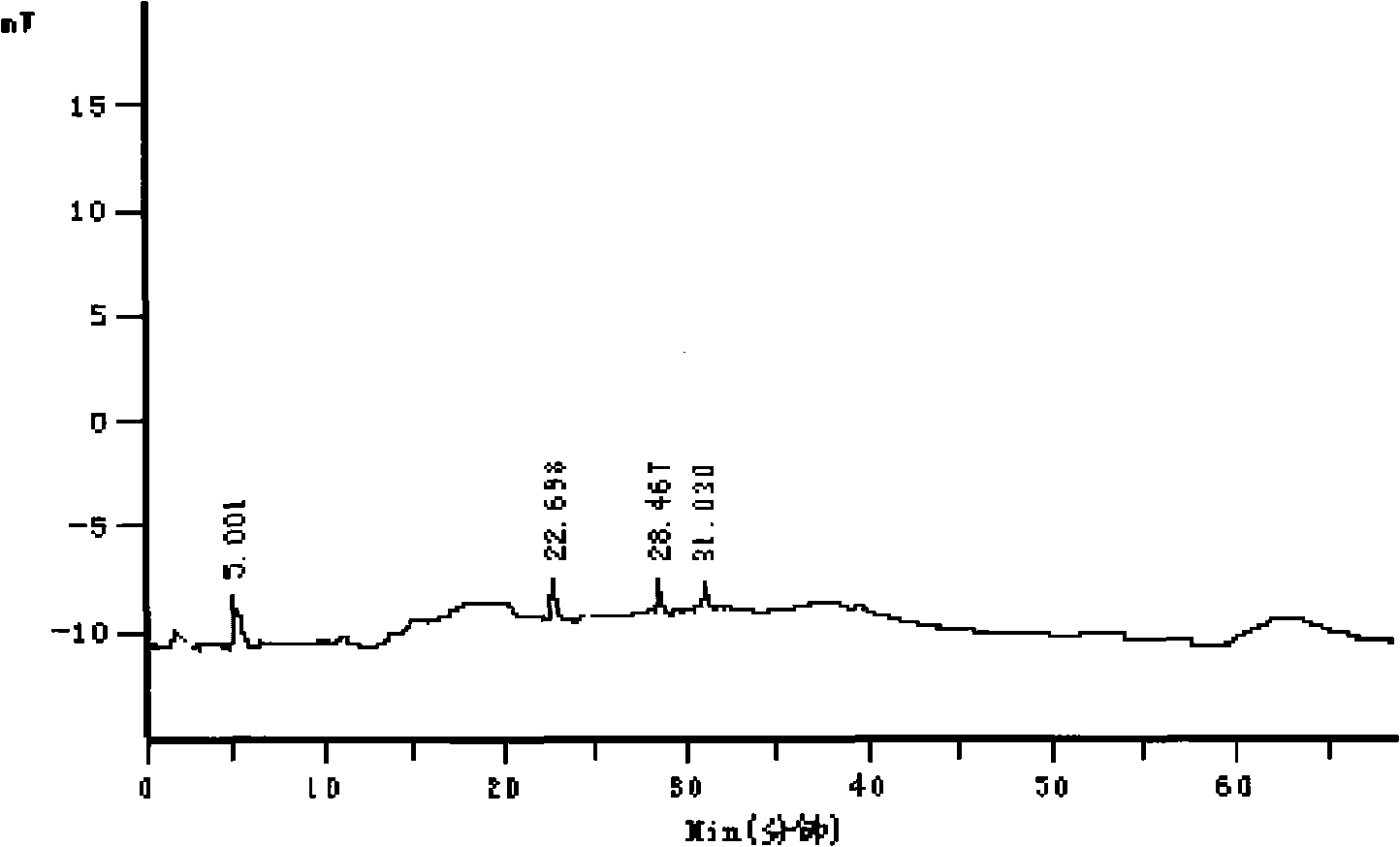

[0025] Reversed-phase high-performance liquid chromatography is used to carry out gradient elution through mixed solvents of different polarities, and the absorption peak of impurities is measured at ultraviolet 254nm, and the content of impurities is calculated by using known impurity reference substances.

[0026] (1) Chromatographic conditions:

[0027] Chromatographic column: YWG-C12H25 column (manufactured by Tianjin Second Reagent Factory);

[0028] Instrument: Shimadzu 10A high performance liquid chromatograph: LC-10AT solvent delivery pump, SPD-10AV ultraviolet detector, Zhejiang University 2010 chromatographic workstation;

[0029] Reagents: acetonitrile (chromatographically pure), potassium dihydrogen phosphate (A.R.), phosphoric acid (A.R.);

[0030] Mobile phase A: 0.7% (weight / volume) dipotassium hydrogen phosphate solution, adjusted to pH 3.5 with phosphoric acid;

[0031] Mobile phase B: acetonitrile;

[0032] Elute according to the gradient listed in the tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com