Fabricating method of cable insulated layer

A cable insulation and manufacturing method technology, applied in the direction of conductor/cable insulation, insulated conductors, insulated cables, etc., can solve the problem that flame retardancy, electrical performance and radiation resistance cannot be satisfied at the same time, radiation intolerance, accident occurrence rate advanced questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

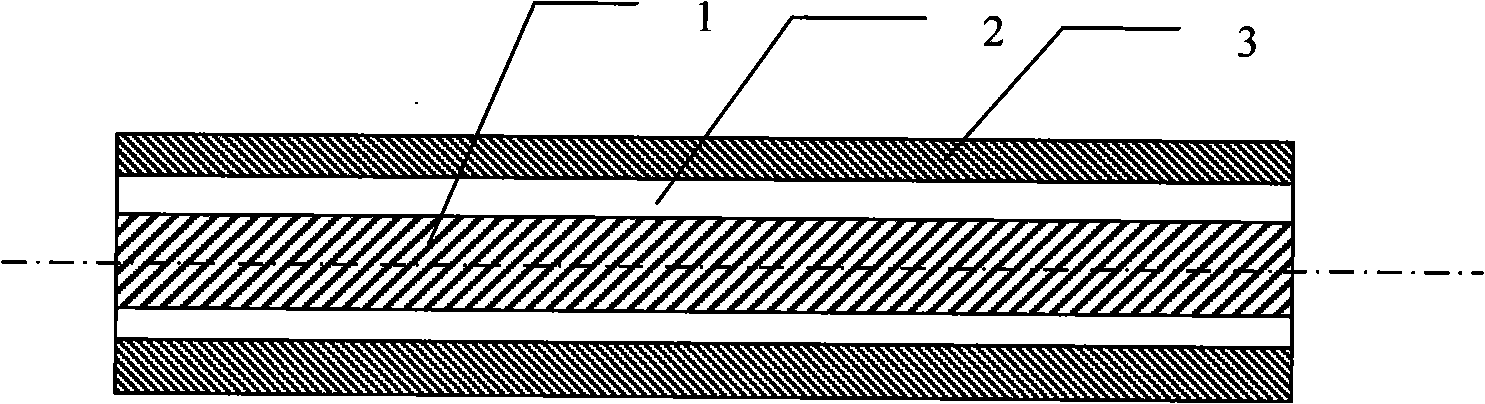

[0027] Embodiment 1: Select low-smoke, halogen-free, cross-linked polyethylene insulating material as the material for the inner layer 2 of the insulating layer, low-smoke, halogen-free, flame-retardant cross-linked polyolefin insulating material as the material for the outer layer 3 of the insulating layer, and the materials for the inner and outer layers The performance meets the following requirements:

[0028] Life expectancy ≥ 60 years;

[0029] Co with a dose of 25 Mrad 60 Radiation resistance;

[0030] Meet NES713 requirements, toxicity index ≤ 2.5;

[0031] Aging at 135±2℃ for 240 hours.

[0032] In addition, the insulation volume resistivity of the inner layer material is ≥1×10 under the conditions of 1kV and 20°C 16 Ω·cm, the material of the outer layer has passed the vertical burning requirement of a single insulated core of IEC 60332-1.

[0033] Extrude the inner and outer layer materials that meet the above requirements simultaneously with two extruders, and ...

Embodiment approach 2

[0034] Embodiment 2: Choose low-smoke, halogen-free, cross-linked polyethylene insulating material as the material for the inner layer 2 of the insulating layer, low-smoke, halogen-free, flame-retardant cross-linked polyolefin insulating material as the material for the outer layer 3 of the insulating layer, and the materials for the inner and outer layers The performance meets the following requirements:

[0035] Life expectancy ≥ 60 years;

[0036] Co with a dose of 25 Mrad 60 Radiation resistance;

[0037] Meet NES713 requirements, toxicity index ≤ 2.5;

[0038] Aging at 135±2℃ for 240 hours.

[0039] In addition, the insulation volume resistivity of the inner layer material is ≥1×10 under the conditions of 1kV and 20°C 16 Ω·cm, the material of the outer layer has passed the vertical burning requirement of a single insulated core of IEC 60332-1.

[0040] Extrude the inner and outer layer materials that meet the above requirements simultaneously with two extruders, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com