Vector control method of non-sinusoidal counter-electromotive-force surface AC magnetoelectric machine

A back-EMF, permanent magnet motor technology, used in motor generator control, electronic commutated motor control, vector control systems, etc., can solve problems such as pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

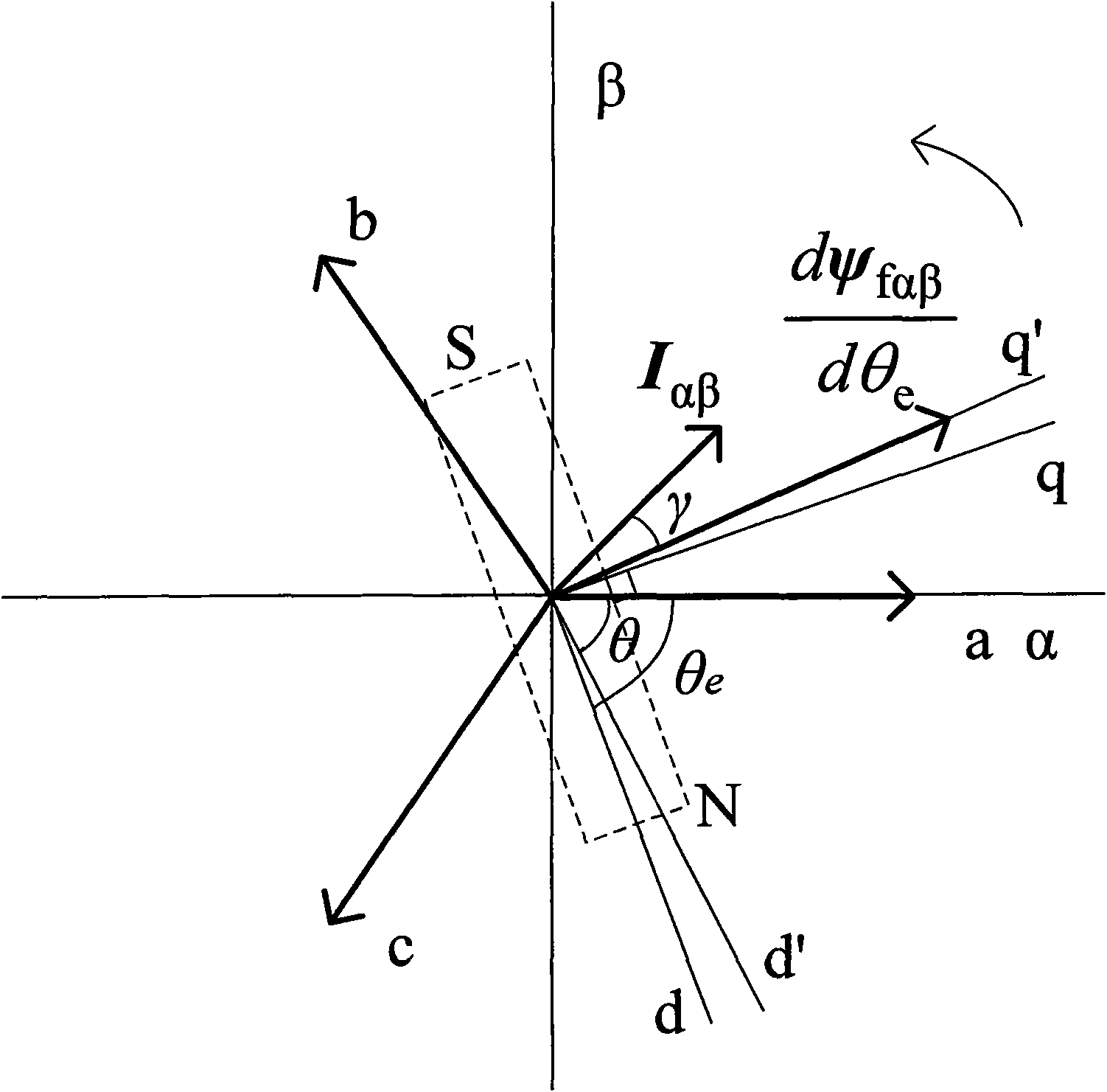

[0021] exist figure 1 Among them, the abc axis is the three-phase coordinate system of the motor, the αβ axis is the static coordinate system of the motor, the dq axis is the synchronous rotating coordinate system of the motor, and ψ fαβ is the permanent magnet flux linkage vector of the αβ coordinate system, θ e is the electrical angle of the motor mover, that is, the angle between the a-axis and the d-axis, which is used to indicate the position of the mover. dψ fαβ / dθ e means ψ fαβ to theta e Derivation is called the permanent magnet flux linkage derivative vector. I αβ is the current vector of the αβ coordinate system, and γ is dψ fαβ / dθ e with I αβ The included angle, N, S are the North and South poles of the magnet respectively. The present invention proposes an asynchronous rotating coordinate system, i.e. the d'q' axis, the d' axis of the coordinate system and the permanent magnet flux linkage derivative vector dψ fαβ / dθ e Coincidentally, the q' axis lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com