Method for manufacturing electronic component supporting plate

A technology for electronic components and manufacturing methods, which is applied in the directions of electrical components, multilayer circuit manufacturing, and electrical connection formation of printed components, and can solve the problems of inability to replace multilayer circuit boards and low circuit density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

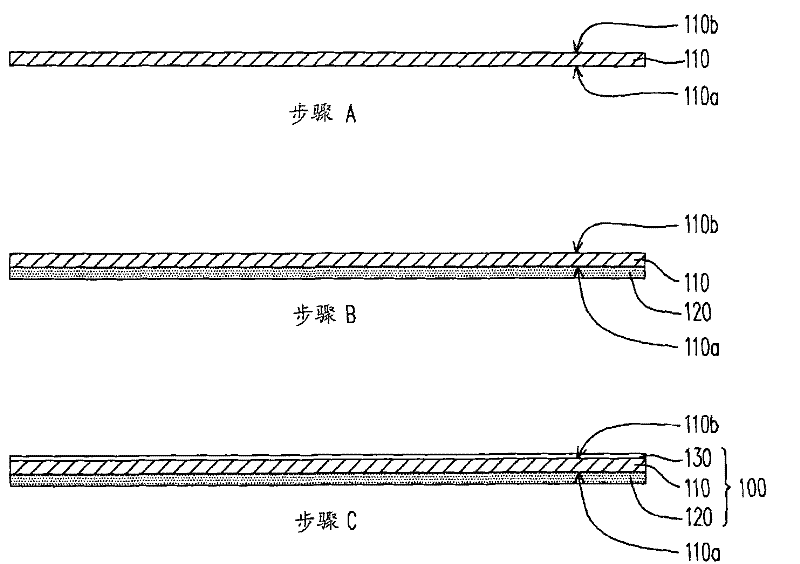

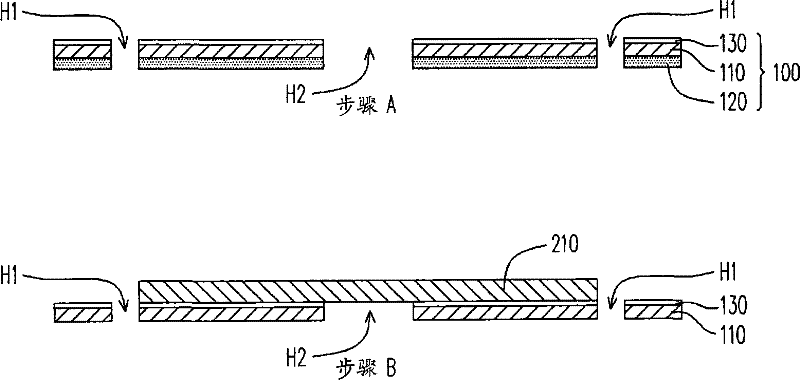

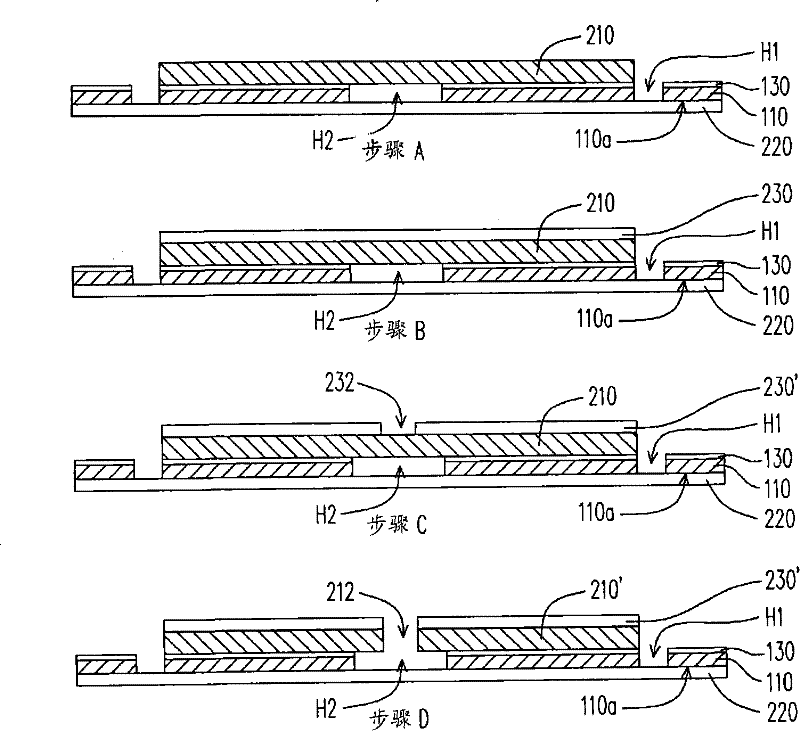

[0028] Figure 1A-1E It is a schematic diagram of steps of a method for manufacturing an electronic component carrier according to an embodiment of the present invention. It should be stated in advance that, Figure 1A-1E The manufacturing method of the electronic component carrier shown is only for illustration, so that those skilled in the art of the present invention can implement it, so the scope of the present invention is not limited to Figure 1A-1E The disclosed manufacturing method of the electronic component carrier also includes other embodiments not disclosed in the drawings. For this reason, the scope of the present invention should still be defined by the claims.

[0029] see Figure 1A , Figure 1A Steps A to C in the above are to fabricate the base material 100 . In detail, first, step A is performed to provide the first conductive layer 110 . The first conductive layer 110 may be a metal foil, such as copper foil, aluminum foil, or foil made of other sui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com