Liquefied petroleum gas or gasoline desulphurization microwave reaction kettle

A technology of petroleum liquefied gas and microwave reaction, which is applied to the gasoline desulfurization treatment device and the field of petroleum liquefied gas, can solve the problems of no device, smoke, carbonization, etc., so as to avoid fire hazards, avoid micro-leakage, and achieve good desulfurization effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

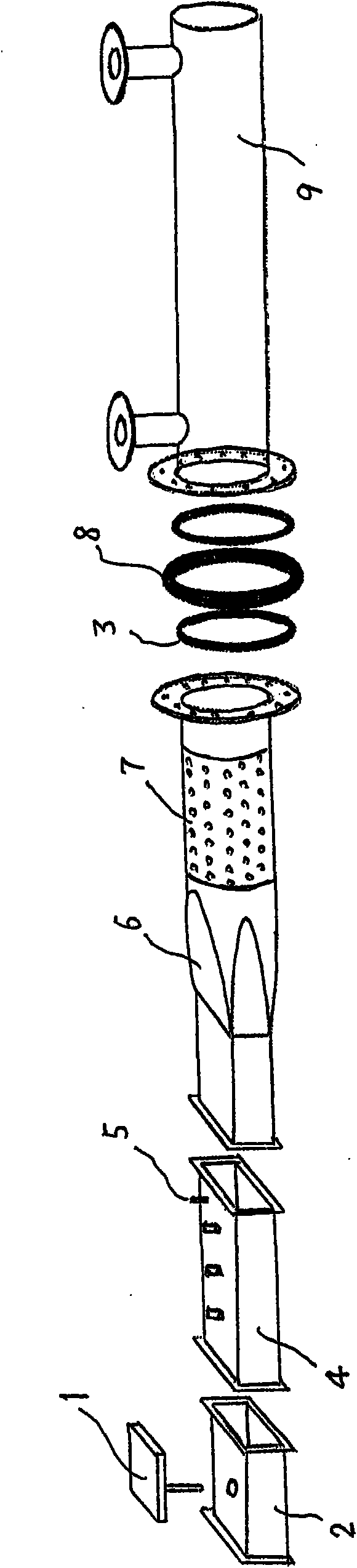

[0012] figure 1 Given the schematic diagram of the structure of the present invention, the structure of the present invention and the functions of each component will be further described below in conjunction with the accompanying drawings.

[0013] figure 1 Among them, 1 is a microwave source, 2 is a microwave coupler, 3 is a sealing ring, 4 is a microwave adjuster, 5 is a power detection device, 6 is a transition waveguide, 7 is a ventilation safety isolator, 8 is an isolation window, and 9 is a reaction cavity. Wherein, microwave source 1 can be existing magnetron and magnetron power supply, figure 1 The magnetron and the magnetron power supply for the magnetron power supply are not drawn respectively; the ventilation safety isolator 7 is a section of circular waveguide, and its side is opened with ventilation holes. There are many holes, and the size and density of the holes determine the The ventilation rate and mechanical strength of waveguide are one of necessary str...

Embodiment 2

[0017] When using the conventional microwave source 1 commonly used in industry, its microwave frequency is 2.45 GHz or 0.915 GHz. Then the corresponding cross-sectional size of the rectangular waveguide in the present invention can be 86.2×43.3mm or 245.0×122.5mm, the corresponding cross-sectional diameter of the circular waveguide can be 100mm or 300mm, and the inner diameter corresponding to the inlet and outlet can be 20mm or 40mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com